Material testing and existing installations are proving the Eriez UHF Eddy Current Separator typically recovers an additional three percent of previously unrecovered Zorba which would be otherwise missed by existing upstream equipment.

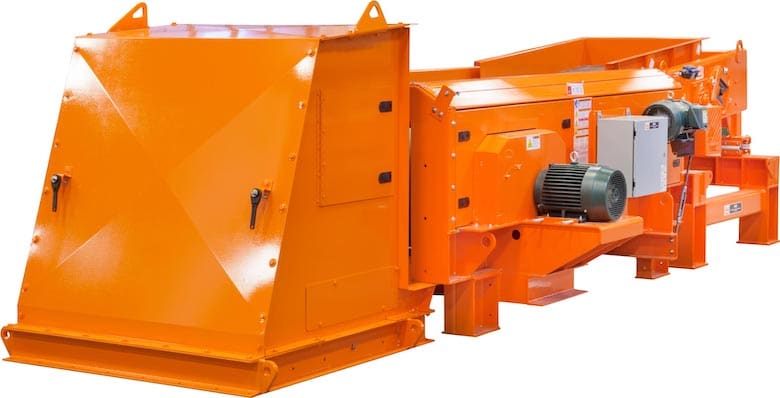

Introduced in 2016, the Eriez UHF Eddy Current Separator generates significant new revenue for scrap metal processors by recovering valuable aluminum, copper, and other nonferrous fines as small as 2-3 mm from automobile shredder residue (ASR), without the requirement for expensive sensor-based or optical sorting equipment.

Leading-edge scrap metal processors, including Illinois-based Scrap Metal Services (SMS) and Ohio-based Garden Street Iron & Metal, utilize Eriez UHF Eddy Current Separators to recover thousands of additional tons of premium Zorba annually. These units feature a state-of-the-art rotor and revolutionary design which creates high-frequency changes. This results in a recovery rate that is impossible to match with traditional eddy current technology.

Separation and Recycling Product Manager Chris Ramsdell explains, “When it comes to upgrading and improving metals recovery, challenges vary from application to application. That is why we encourage processors to send their material samples to us for testing in our Central Test Lab.” He says, “Recovery results using a customer’s own sample effectively demonstrates the potential profit that customers can gain by implementing Eriez solutions.” He adds, “When dealing with the fines waste fraction, the UHF Eddy Current Separator often proves to be the ideal equipment choice.”

According to Eriez, the typical input to the UHF Eddy Current Separator is the fines waste fraction from a customer’s existing nonferrous processing line. The product of the UHF Eddy Current Separator is a high-grade Zorba package with considerably higher-than-normal copper content. Typically this fine Zorba product is comprised of 20 percent or more red metals content, which can be sold at a premium.

Tests performed in the company’s Central Test Lab, located in Erie, Pennsylvania, often begin with around five to 10 gallons of material. Ramsdell says, “If the smaller scale tests look promising, we usually arrange a larger scale test at an existing installation to validate the recovery data.”