The Pre-shredder was first utilized to process a stream of C&D debris directly to a “B” sorting at a processing rate of 75 Tons per hour resulting in a homogenous fraction of <20” (500mm). The consistent material size increased the screening quality and made it easier for the hand pickers to sort out different material streams with the emphasis on wood.

Materials included demolition wood, doors, metals, aggregates, plastics, and even shredded portable restrooms. All materials were loaded directly into the shredder with an excavator.

Once all material was processed for the sort line the machine was moved to another location to shred directly into a baler. The shredded material baled easier and compacted better, resulting in a 25% increase in bale weights. The operators and attendees were impressed by the quality and ease of operation of this robust piece of equipment.

For the next 2 days, the METSO M&J 4000-6 Pre-shredder was then moved to a Waste Transfer Station feeding directly into railcars. At this facility, Residential and Commercial waste streams are processed and loaded into railcars. The machine was loaded with a front-end loader with a 13 cubic yard bucket to keep up with the massive capacity of the shredder. Among other materials, they also processed some waste streams that included a very light, fluffy, compacted canvas type of material. It was a breeze for the METSO M&J 4000-6 to tear this material up and amazed the customer how well the machine was able to handle it. In this setting, the machine processed approximately 120 tons per hour filling up railcars to capacity without overflow or a need to compact the material any further.

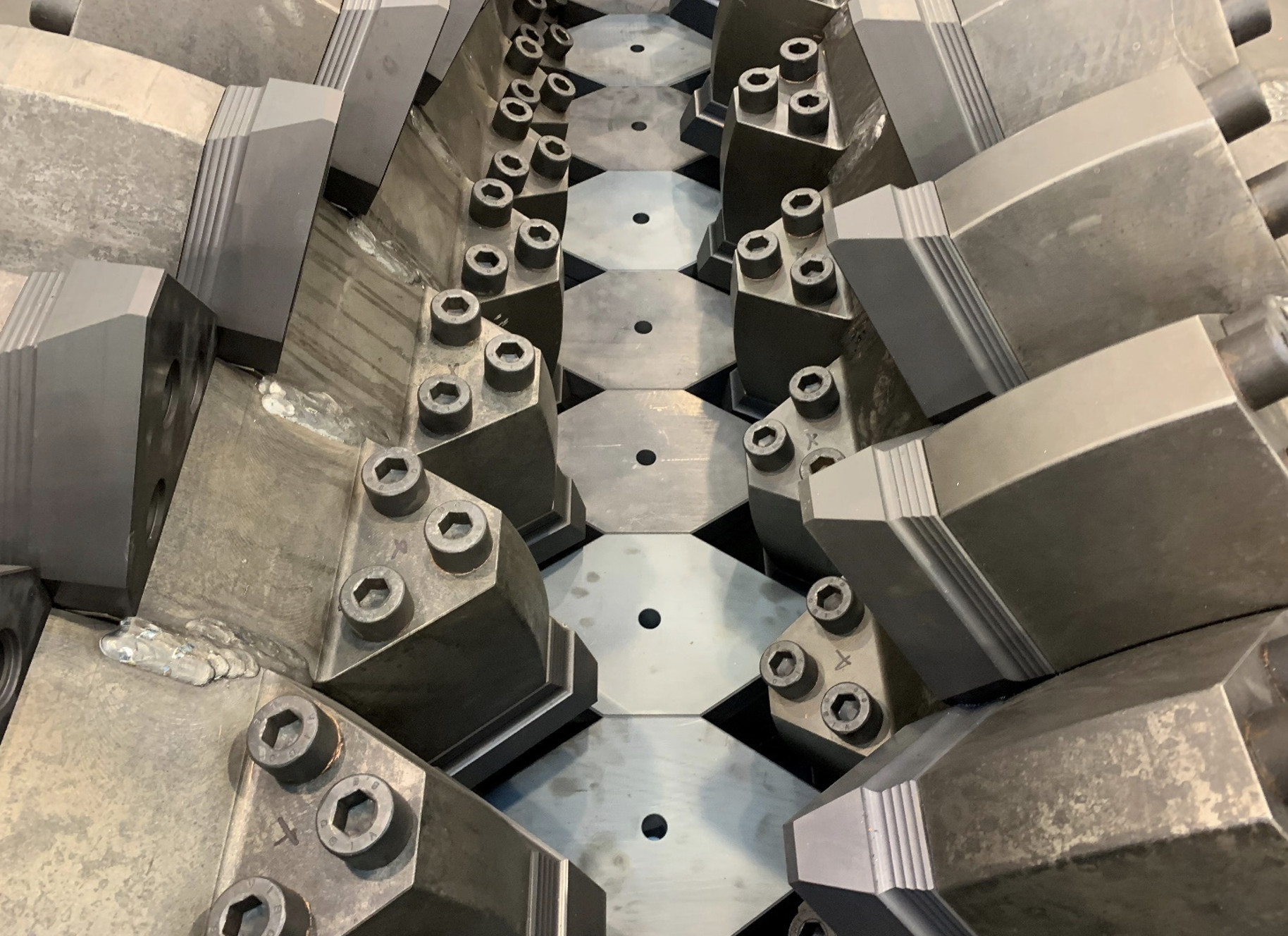

Pre-shredders must be tough machines. This METSO M&J 4000-6 unit is built with a CAT 540 diesel engine that uses ~14 gallons per hour of fuel at full shaft speed and shredding capacity. The shredding shafts are independently driven by dual hydrostatic drives, allowing for rapid directional changes of the shafts and knives.

The fans on the cooling radiators automatically change directions to keep the system clean and to reduce end of shift clean-up time for the maintenance team. Remote monitoring allows all operations and diagnosis of the machine to be seen and analyzed by the manufacturer (at customer’s request) to assist with operations, maintenance and issues, and help increase the lifespan of the machine and uptime of the facility’s operations.

If the machine encounters any un-shred able materials (such as a 12” diameter steel drum filled with concrete) in the waste stream it will reverse five times before it will shut down and give an alert. In these seldom cases, it is possible to empty the machine by utilizing the unblocked shaft manually. No need to dig through a large amount of material to remove the blockage.

Since the machine does not have any bolted in tools, screen bars etc. the maintenance is a simple process of hard facing the cutting tips and cutting table. The intervals vary depending on the abrasiveness of the material processed with the machine.

eFACTOR3, LLC is based in Charlotte, North Carolina, and is a distributor and service partner for the METSO Shredders that are available in a mobile or stationary configuration. The METSO parts distribution center for North America is in Columbia, South Carolina.