Showdown with fossil fuels

The plant can receive up to 250,000 tonnes annually of dry mixed commercial, industrial, construction, and demolition waste and recover commodities and convert the residuals to PEF. PEF is used as a substitute for fossil fuels in both domestic and offshore cement production markets. Among other things, the facility will supply PEF to Boral Australia, Australia’s largest cement supplier, for its cement kiln as a replacement for coal.

In total, it is estimated that the factory’s production can replace over 100,000 tonnes of coal consumption per year, equivalent to removing 20,000 cars off the road regarding greenhouse gas emissions reduction.

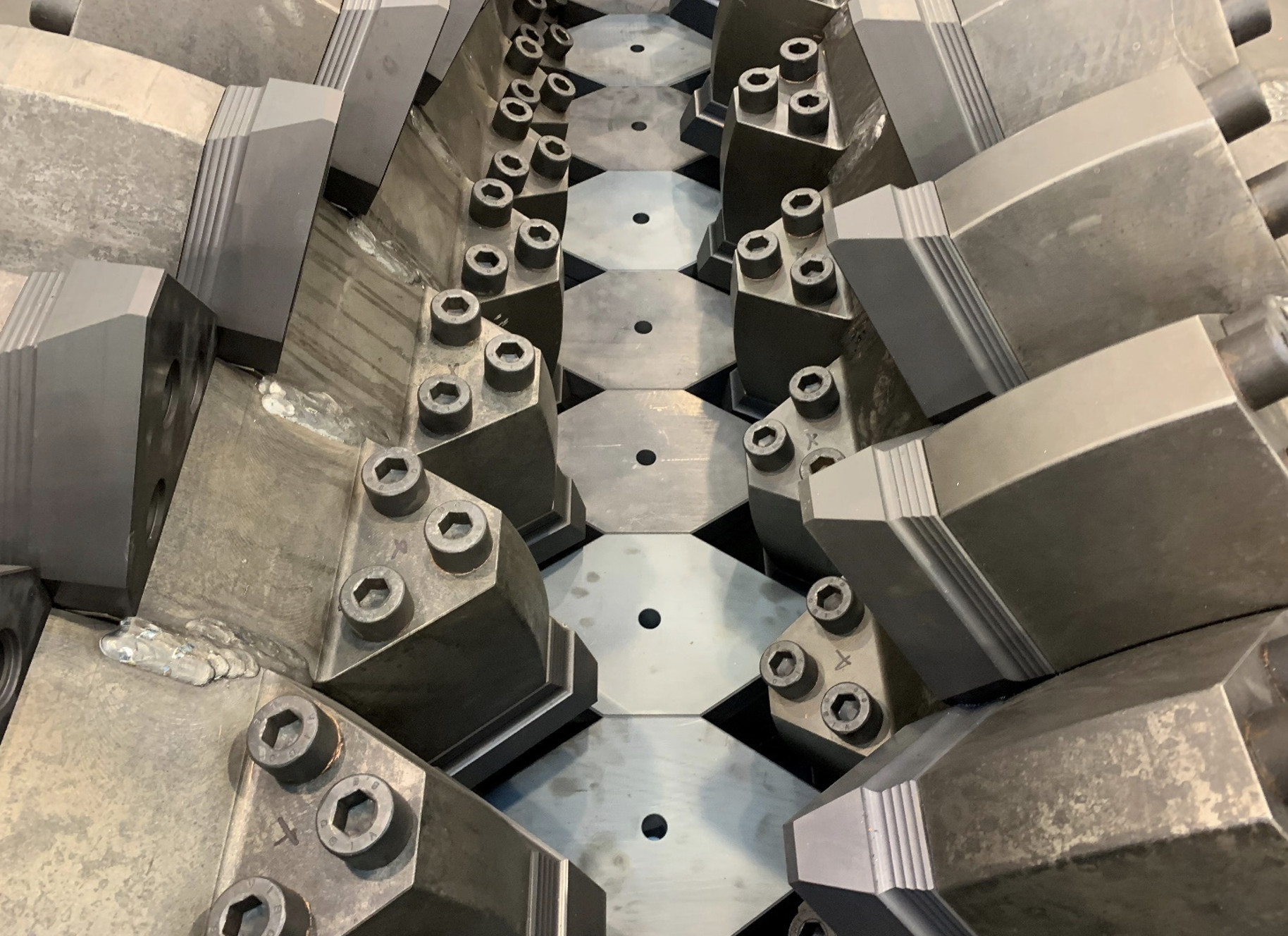

Flexible and reliable PreShredder

Metso Waste Recycling is the completely right partner when it comes to turning waste into resources. The market’s highest reliability and impressive output (up to 50 tons per hour) placed M&J PreShred 6000S at the forefront of the queue when the time came to select a PreShredder for the new factory. It is one of the largest PreShredders on the market and a machine that is widely recognized for ensuring maximum uptime in production. And it can practically eat through all kinds of materials – including Industrial (C&I), Construction, and Demolition (C&D). In short, a perfect partner to meet the factory’s ambitions.

The company

ResourceCo was founded in 1993 and is one of Australia’s largest recycling businesses, accepting and processing over two million tonnes of waste per annum. Cleanaway Waste Management is Australia’s leading total waste management, industrial and environmental services company.

“We invest only in proven technologies to achieve our goal of playing a key role in Australia’s ambition to reduce waste to landfill and reduce CO2 emissions,” says, the customer.