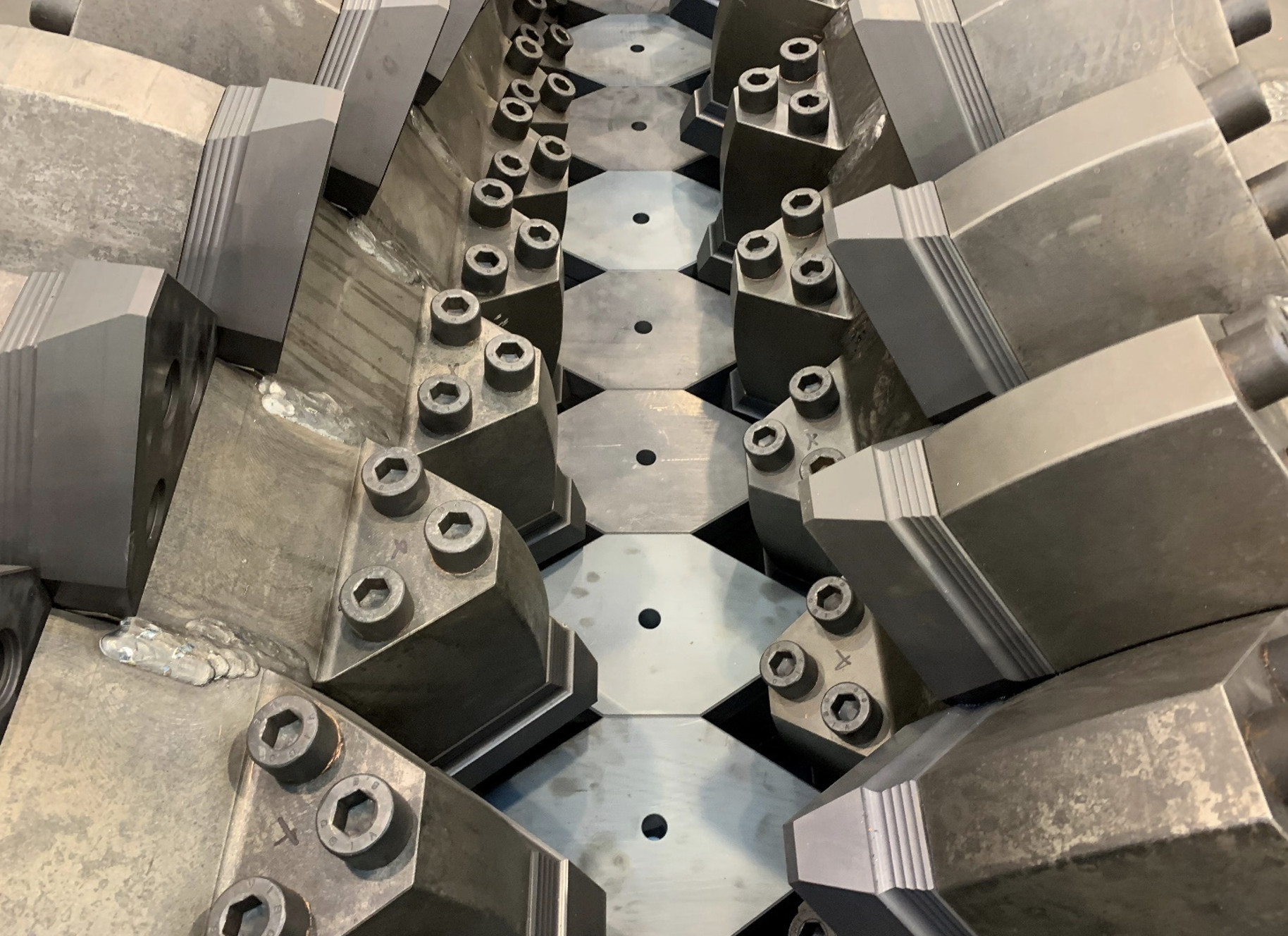

At IFAT, there was particular interest in M&J Recycling’s latest addition – the modular M&J P250 pre-shredder, which is the Next Generation of the former flagship M&J 4000S.

The pre-shredder’s modular design delivers many daily benefits and, ultimately, has a greatly beneficial impact on what it costs to have the machine running. The individual parts can be dismantled quickly and easily – thus saving both time and money on servicing the machine, as well as ongoing maintenance.

“The visitors to our stand were very excited about our new, modular pre-shredder. Understandably, everyone in the industry has a strong focus on avoiding long and expensive downtime, so easy maintenance is a super important competitive parameter. And our E-drive option will be a ‘must have’ for many customers. We are extremely pleased with the reception of the M&J P250 and feel convinced that it will quickly gain a foothold in the market”, said Uffe Hansen, CEO of M&J Recycling

eFactor3 awarded Partner of the Year

During day 2 at IFAT M&J Recycling hosted their annual partner seminar and the absolute hightlight was when Hartmut Bendfeldt, President of eFactor3 received the M&J Partner Award 2021.

“eFactor3 has made great decisions and achieved outstanding results as our sales and service partner in the USA”, said Morten Kiil Rasmussen, Commercial Director at M&J Recycling.

Significant savings on the operating budget

All parts on the M&J P250 can be removed and replaced in an ultra-short time if necessary. And the modular design also has the great advantage that you only have to replace the parts that are actually worn.

Combined, this ensures high uptime in production and large savings on the operating budget, because fewer hours and spare parts are spent on maintenance and service. The modular design also makes the service work on the machine safer and work-friendly.

Go green with E-drive

The M&J P250 on display at IFAT was equipped with M&J Recycling’s newly developed E-drive solution, which is an obvious choice for a large number of waste types. It shreds with the same force as the hydraulic solution, but uses up to 50% less power.