Rubber recycling process

There is a complete industry dedicated to the rubber recycling process.

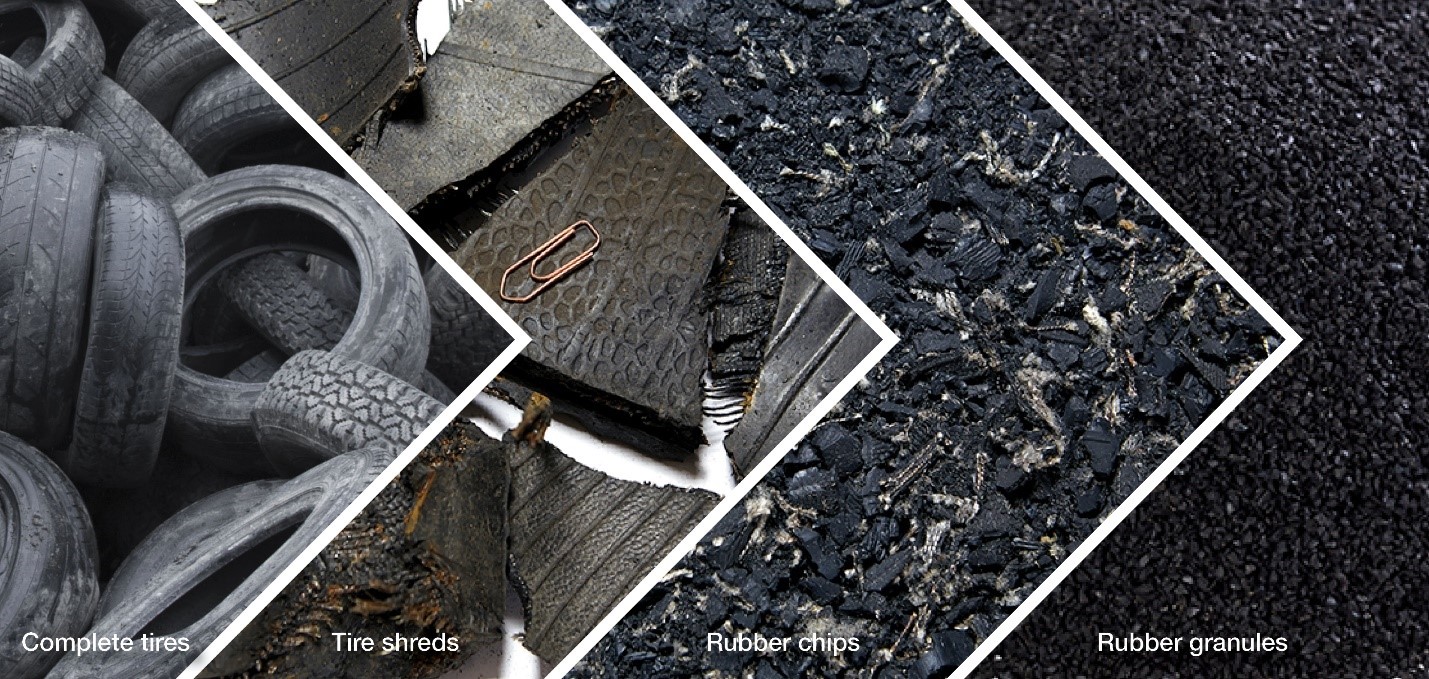

In the typical rubber recycling process, rubber is collected, shredded, sorted, and finally devulcanized to transform waste rubber into raw material.

Collection of rubber waste

Rubber waste is collected from deposits by individual households and from landfills whereafter it’s sent to recycling centers. In most cases, this rubber waste is in the form of a waste tire (ELT), the major rubber product.

Size reduction of rubber waste

To reduce rubber products into smaller particles a shredder/granulator is often the machine of choice. Reducing the size of rubber into smaller particles allows for easier processing during the sorting and devulcanization processes.

Click here for manufacturers of shredders for this application.

Crumb rubber

Rough crumb rubber is more manageable than whole waste tires but is not very useful. The rough crumb rubber still contains fragments of reinforcing fabric and wire.

Depending on the end market, additional processing may be necessary to remove those impurities and create a finer crumb size, or mesh.

Sorting of rubber waste

Sorting of rubber waste often occurs during the size reduction process. During this sorting process, steel fibers are removed from the rubber waste stream by means of a magnet.

Textile fibers are separated from the waste stream by using (shaking) screens, (wind) sifters, (low vacuum) suction equipment.

Devulcanization of rubber waste

Devulcanization of rubber waste is a process that reverses the “vulcanization” of rubber, recycling it so that it can be vulcanized again. This process converts waste rubber into a new “virgin” raw material.

Definition Devulcanization: A process that causes the selective breakup of the sulfur-sulfur (S-S) and carbon-sulfur (C-S) chemical bonds without breaking the backbone network and without degrading the material.

The devulcanized rubber can be mixed with virgin rubber or with other kinds of matrices to give new compounds without generating a significant decrease in mechanical and physical properties.

Many devulcanization process types are presented: chemical, microwave, ultrasound, thermomechanical, etc.

Other waste rubber processes:

Beyond this, there are other options for the processing of the waste rubber. They include:

Freezing

This concerns the freezing of the waste rubber to process its recycling. While this process is less common, it’s still as effective as devulcanization. In this process, the rubber gets frozen with the use of liquid nitrogen.

After the rubber is frozen, it gets processed in mills where it is grounded to create granules. These granules then become suitable to create new rubber products.

Pyrolysis of rubber waste

Pyrolysis of rubber waste offers an economically and environmentally beneficial method for transforming waste rubber into useful products, heat, and electrical energy.

Pyrolysis is a recycling method that involves heating (thermal decomposition) whole or shredded waste rubber in an oxygen-free reactor to break the polymers down into molecules.

These molecules vaporize into gases that travel from the reactor to a condensing system where the gas transforms into liquid oil.

Non-liquified gases return to the combustion system as fuel. The liquid oil collected by pyrolyzing rubber waste is often required for processes in the metal, alloy, or chemical industry.

Image:

Image: