Versatile and rapidly deployed.

Can be supplied in stationary or mobile configurations. Unlike any other shredders, CM systems come as a turnkey package and include infeed conveyor, discharge conveyor, subframe, stands and platforms as well as a control panel with PLC Controls. All systems are prewired and tested at the factory. This unique feature allows systems to be quickly installed and commissioned in the field. Most systems are operational in two-three days after arrival on site. This saves thousands of dollars in freight, site preparation, and field installation costs.

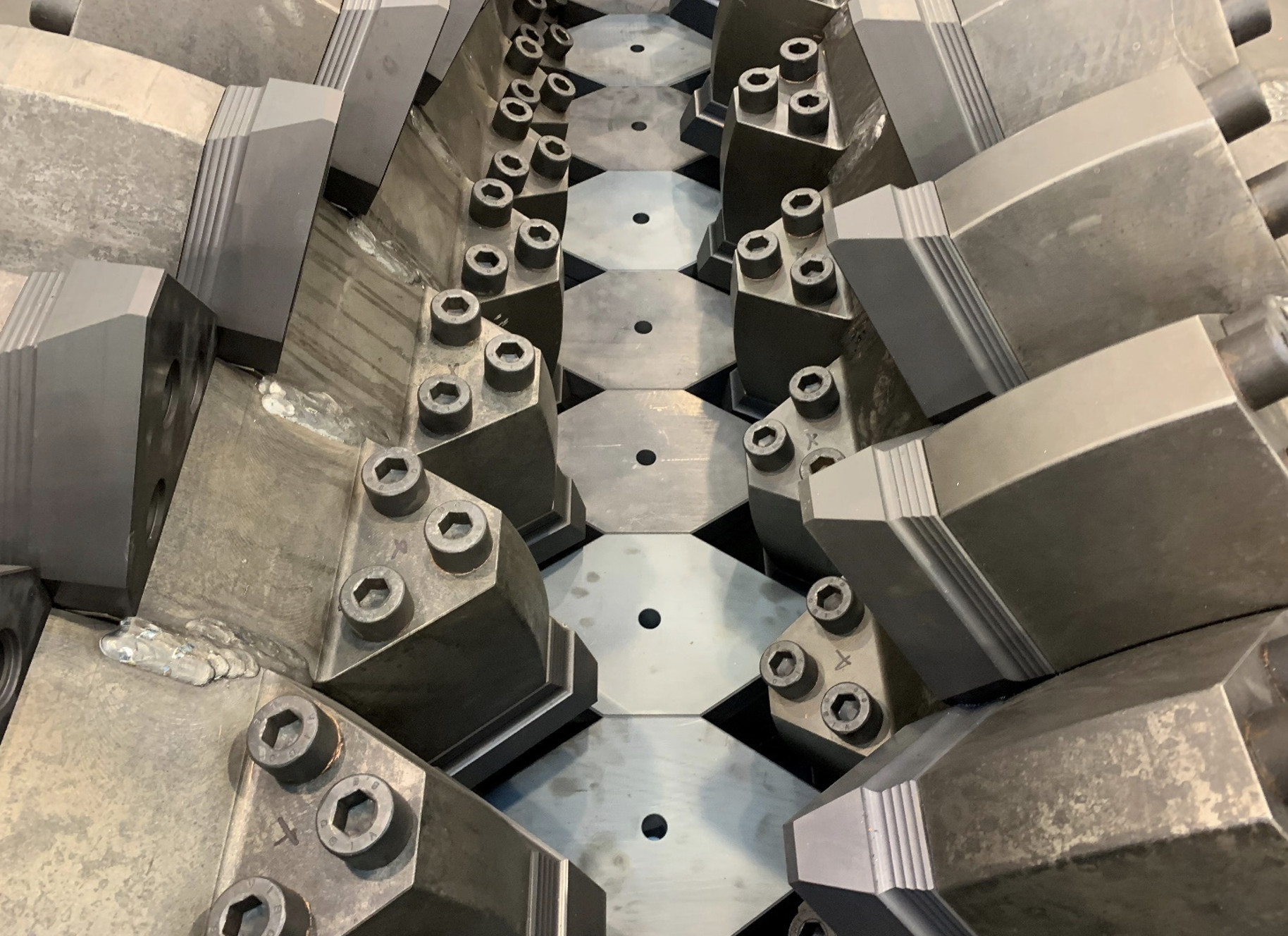

Reduce your knife cost by over 300%

The cost associated with knives is the leading cost driver for operating a shredder. This system can be equipped with CM’s patented knife technology, which allows it to process more tires at a lower cost. CM knives can be repositioned, reground and reused up to 6 times. CM’s replaceable knife systems run longer between knife changes, take less time to change and cost less to replace. This allows you to reduce your knife cost by over 300% and provide the least cost of ownership of any shredder on the market today.