The recycling of electronic waste involves several key stages. Initially, products are dismantled and separated into components such as circuit boards, alloys, power supply units, connectors, production scraps, and even precious metal-bearing items. At this stage, the materials are still highly heterogeneous and require specific treatments to become secondary raw materials suitable for reuse.

The typical treatment process includes the following steps:

- Mechanical Treatment

- Thermal Treatment

- Chemical Treatment

- Electrochemical Treatment

Mechanical Treatment

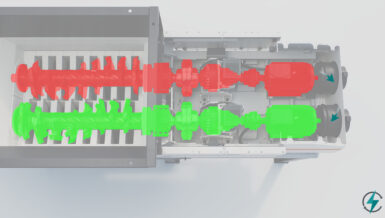

Circuit boards with a feed size of up to 400 x 400 mm can be processed using the CM4000 Cutting Mill. Each board can be reduced to a particle size of 4.00 mm in under 20 seconds. This step produces a more homogeneous material that still requires further refinement.

Thermal Treatment

To concentrate and upgrade the metal content, a thermal treatment is carried out. This step helps remove organic compounds, which may interfere with the efficiency of the subsequent chemical treatment.

Chemical Treatment

A hydrometallurgical process is used to recover metals by immersing the materials in chemical baths. Techniques such as cementation, precipitation, and liquid-liquid separation are applied. The resulting concentrate typically achieves a purity of around 80%.

Electrochemical Treatment

Following chemical processing, an electrochemical refining step is used to achieve extremely high metal purity — typically greater than 99.9%.

Sample Preparation of Computer Boards

To ensure accuracy and consistency while minimizing human error, LAARMANN offers a fully automated sample preparation solution. The system includes:

- Cutting Mill or primary shredder

- Vezin sampler

- Dust collector

- Product collector on load cell

- Electronic control unit

- Structural framework

System Configuration:

- The Cutting Mill is mounted on a platform and connected to a vibratory feeder, which feeds into the Vezin Sampler.

- The Vezin Sampler is installed under the feeder to take representative samples from the flow of pre-cut material.

- A 1200-liter sample collector is placed under the sample divider to collect the processed material. The collector is mounted on guided wheels and positioned on a load cell to allow for accurate weighing.

- The load cell is fitted with air bag clamps to ensure stable and precise measurement during the collection process.