Construction and Demolition Waste Recycling

Our latest E-mail campaigns for Construction and Demolition Waste Recycling

- E-Market Insight: Innovations in C&D Waste Recycling February 20, 2025

- Construction and Demolition Waste Recycling – E-Market Insight: February 15, 2024 February 15, 2024

- Construction And Demolition Waste Recycling – January 9, 2020 January 9, 2020

- Construction And Demolition Waste Recycling – October 10, 2019 October 10, 2019

Experts for Construction and Demolition Waste Recycling

Olli Heinonen

Tana OyTana Oy’s Vice President of Sales and Marketing Mr. Olli Heinonen has a strong knowledge of global sales and heavy machinery business. Prior to his current role, Olli was the Director for a consumables product line at Metso Outotec and Metso. At Tana Oy, Olli is responsible for overseeing the sales and marketing efforts, ensuring that the company's products meet the evolving needs of customers in the waste management industry. His leadership contributes to Tana's strong growth path and the mission of delivering innovative and efficient solutions that help manage waste sustainably.

Daniel Wresnik

UNTHA shredding technologyDaniel Wresnik, Head of Sales and Business Development BU Waste & Recycling in the DACH region at UNTHA, is a proven expert with extensive experience in waste recovery and recycling. Since joining UNTHA in 2009, he has developed numerous tailor-made shredding solutions for clients across Europe – including in Austria, Germany, Italy, France, Greece, Switzerland, and the Benelux countries. His core expertise lies in high-throughput industrial shredders for a wide range of input materials – from municipal and commercial waste to the production of alternative fuels (RDF/SRF). Together with his team, he develops high-quality, efficient, and economically viable system solutions – always with a strong focus on customer benefit. His guiding principle: “There are no problems – only solutions.”

Tom Jansen

TOMRA RecyclingAfter studying Chemical Engineering at the Technical University of Eindhoven, the Netherlands, Tom started working as Sales Engineer at Innov-X Systems. He initially focused on selling handheld XRF equipment in the Benelux, while gradually extending the geographical territory over the years. From 2007 he was heavily involved in the pioneering of automated XRF sensor technology, bringing this new technology to the metal scrap market worldwide. Tom joined TOMRA Sorting (then Titech GmbH) in 2011 as Sales Manager responsible for the Metal Recycling market in the Netherlands and Belgium. Since then, in his role as Segment Champion for the ELV shredder segment, he has also supported the metal recycling market in the Middle East region, Italy, Greece and projects in several other countries.

Xu Xifeng, the founder of Keson and vice president of Jiangsu Low Carbon Environment Design Institute of China. He has been engaged in solid waste recycling industry for more than 10 years, and has unique insights on solid waste overall solutions and resource recovery and sorting systems. He has visited well-known solid waste treatment companies in the Middle East, Europe, America and other regions, introducing standardized, refined and systematic management concepts of global top enterprises to his enterprises, and transforming advanced technologies and processes into productive forces. Within five years of solid waste sorting technology and waste resources in the field of rapid layout, his products are sold in 17 countries and more than 40 regions.

Dan Fairest

M&J RecyclingAt M&J Recycling, my role as the UK & ROI Sales Manager centres on providing top-tier shredding solutions tailored to the waste and recycling sector's dynamic needs. My competencies lie in ensuring each solution aligns perfectly with our client's operational objectives. Capitalising on my 20-plus years of experience in the industry, my mission is to deliver reliable and innovative shredding technology that meets the rigorous demands of materials processing. My professional career is driven by the satisfaction of resolving complex waste management challenges, fostering long-term client relationships, and steering projects to completion with efficiency and precision.

Ankit Kalola

Fornnax Technology Pvt. LtdMr. Ankit Kalola serves as the Global Head – Sales at Fornnax Technology Pvt. Ltd, where he has played a pivotal role in shaping the company’s sales strategy and global footprint. A seasoned expert in shredding systems and end-to-end recycling solutions, he excels in building client-centric approaches, driving market penetration, and aligning technical solutions with customer needs. His strategic direction has significantly contributed to Fornnax’s success across diverse industries and geographies. Mr. Kalola’s leadership continues to fuel growth, innovation, and long-term partnerships worldwide. For further information or to connect with Mr. Kalola, please reach out at +91-9033077711 or email: info@fornnax.com.

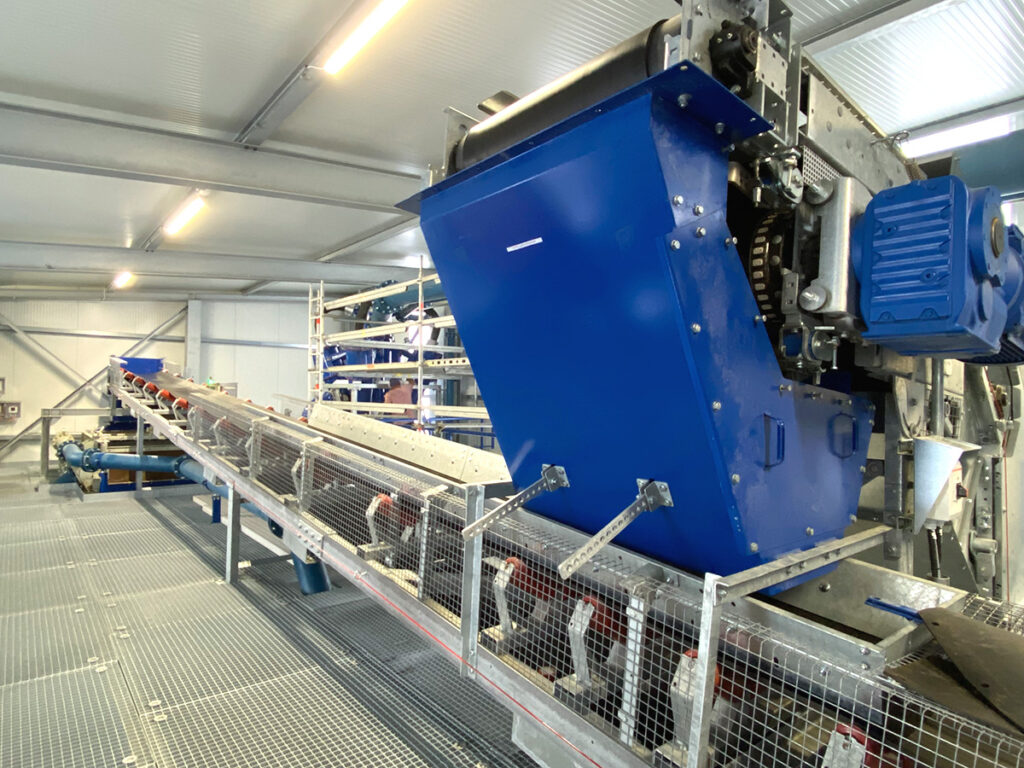

Construction and demolition (C&D) recycling involves the systematic recovery, separation, and processing of materials generated during the construction, renovation, and demolition of buildings, infrastructure, and civil works. These activities produce large volumes of waste, including concrete, wood, metals, masonry, asphalt, insulation, plastics, and other reusable or recyclable materials that would otherwise be disposed of in landfills.

Through advanced sorting and processing technologies, C&D recycling facilities are able to reclaim valuable materials and reintroduce them into new construction projects or other industrial applications. Concrete and masonry can be crushed and reused as aggregates, metals can be separated and recycled, and wood can be repurposed or converted into alternative fuels or engineered products.

C&D recycling plays a vital role in reducing landfill use, conserving natural resources, and lowering the environmental footprint of the construction sector. It also supports compliance with increasingly strict waste regulations and sustainability targets. As urban development and infrastructure renewal continue to accelerate, efficient C&D recycling systems are essential for enabling circular construction practices and promoting a more resource-efficient built environment.