ALLU, a global leader in screening and crushing bucket attachments, proudly introduces its newest innovation for the recycling sector: the ALLU Asphalt – a powerful, hybrid screening solution engineered specifically for processing cold-milled asphalt and reclaimed asphalt pavement (RAP) in a faster, cleaner, and more cost-effective way.

“Globally, there’s a clear shift toward sustainable infrastructure in construction business. Asphalt recycling plays a major role in this movement, and our new ALLU Asphalt Bucket empowers contractors to turn reclaimed and cold-milled asphalt into high-quality, reusable material—directly on site. It’s a smarter, more profitable way to work, and we’re proud to help drive this transformation across the industry.” — Peter Grönholm, CEO, ALLU Finland Oy

As municipalities, contractors, and asphalt producers look for smarter ways to reuse milled asphalt, the ALLU Asphalt Bucket delivers a transformative advantage. This purpose-built attachment crushes clumps, screens fines, and separates oversized particles – all in a single pass.

“At a time when efficiency, sustainability, and profitability are key, the ALLU Asphalt Bucket ticks all the boxes,” says Tom Chapman, Managing Director at MRD Plant, UK. “It does the job of a mobile impact crusher – but at a fraction of the cost and with far less complexity on-site.”

Efficiency Meets Profitability

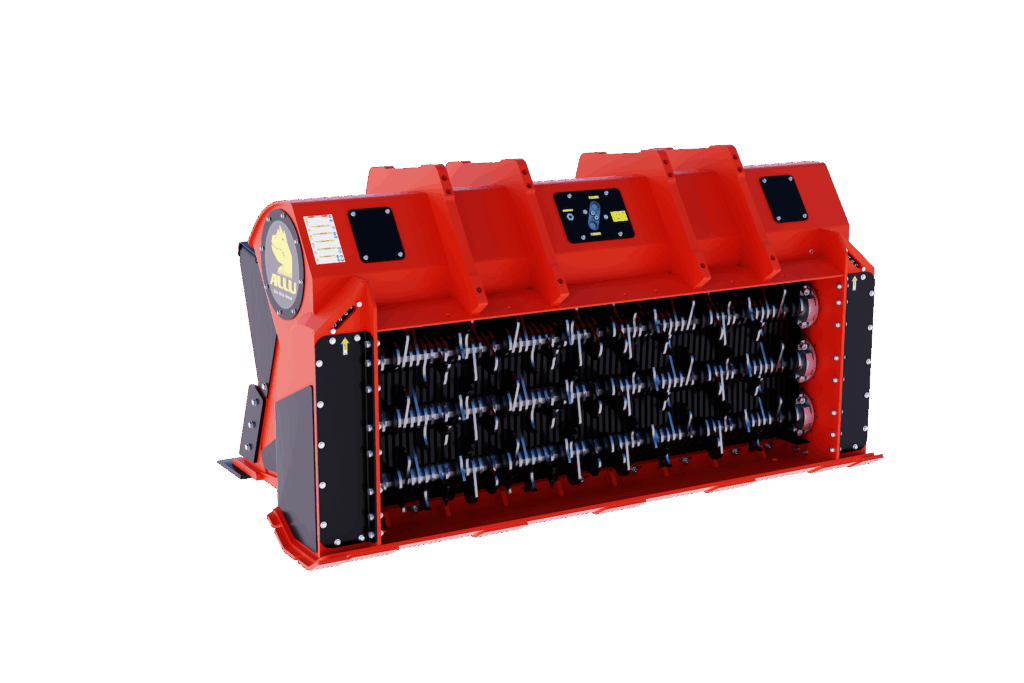

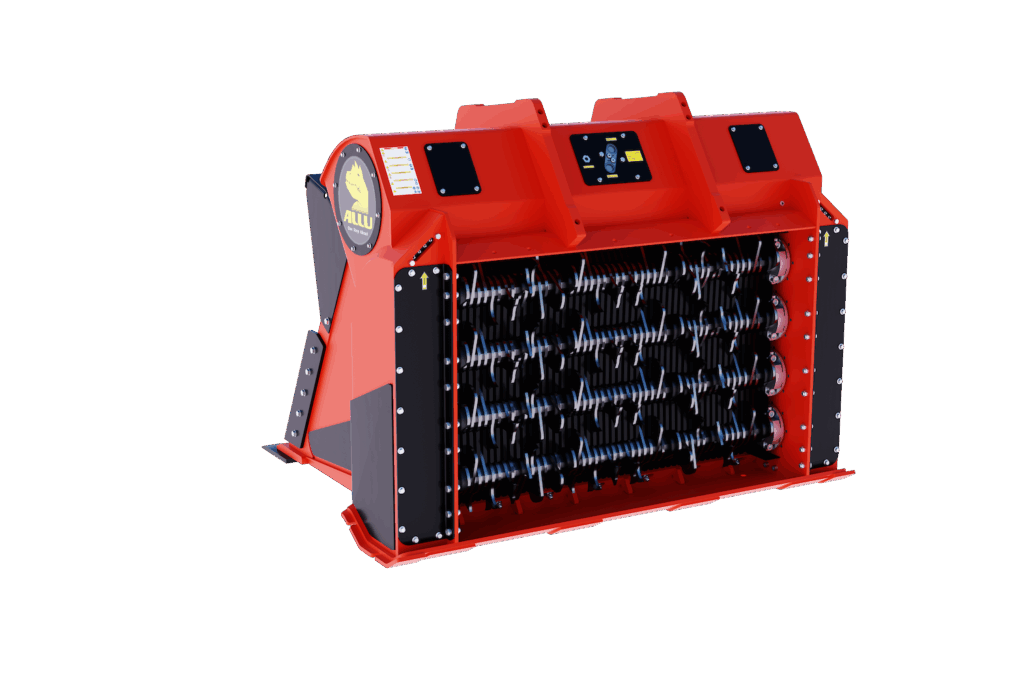

The Asphalt Bucket utilizes a hybrid blade configuration – a mix of screening and crushing blades – to fine-tune performance and achieve consistently high-quality end products. This combination allows operators to process cold-milled asphalt directly at the source without additional crushing equipment.

“The hybrid blade setup is what makes this bucket so effective—it delivers just the right mix of crushing force and fine screening to process asphalt efficiently in a single step,” says Peter Grönholm.

With nominal screen sizes of 12, 16, and 25 mm, the bucket can produce over 95% of finished material below target size, drastically reducing reprocessing needs.

Key features include:

- One-Step Operation: Crushes and screens simultaneously, eliminating the need for separate pre-crushing or secondary equipment.

- Lower Total Costs: Reduces reliance on mobile impact crushers, cutting fuel consumption, wear part expenses, and overall ton-per-cost rates.

- Proven Throughput: Models deliver up to 250 tons per hour, with rapid drum change-outs thanks to the Variable Drum technology.

Designed for Today’s Job Sites

The ALLU Asphalt Bucket is available in several sizes for 25–45 ton excavators and 15–30 ton wheel loaders. Its robust design includes a serrated cutting edge and reinforced frame, tailored for aggressive processing.

Whether it’s pre-crushed demolition asphalt or compacted cold-milled material, the ALLU solution is engineered for reliability, mobility, and productivity – even in tight or urban work sites.