Keson, a leading provider of integrated solid waste sorting solutions, is driving this change with cutting-edge technologies—including its Combined Eddy Current System and AI-Powered Intelligent Sorting Systems—enabling clients to achieve more precise, cost-effective, and intelligent metal recovery.

Industry Challenge: Complex Material Streams Require Smarter Separation

In today’s recycling environments—ranging from e-waste and ELVs to industrial scrap—ferrous and non-ferrous metals are often heavily mixed, making efficient separation increasingly difficult. Traditional sorting systems face several key limitations:

- Ferrous metals interfere with non-ferrous separation;

- Output material streams lack consistent purity;

- Manual sorting is costly, slow, and error-prone.

Keson addresses these challenges through a two-stage solution combining pre-separation of ferrous metals and intelligent classification of non-ferrous materials, covering the full process from coarse to fine sorting.

1. Combined Eddy Current System: Two-Step Separation of Ferrous and Non-Ferrous Metals

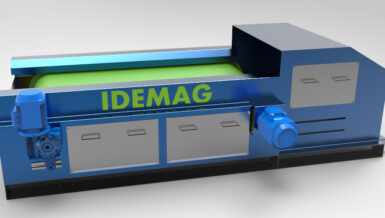

▶ System Structure: Magnetic Drum + Eddy Current Separator

Keson’s Combined Eddy Current System features two integrated modules:

- Magnetic Drum Separator

A high-intensity permanent magnet drum captures ferrous metals like iron, steel, and nickel, removing them early from the flow and protecting downstream components. - Eddy Current Separator (ECS)

The remaining material then passes through a high-speed rotating ECS rotor, which generates eddy currents to eject non-ferrous metals such as aluminum, copper, and brass with precision.

▶ Technical Highlights

- Sequential separation flow: Ferrous removal ensures high ECS accuracy;

- Adaptable design: Handles shredded, mixed, or contaminated input;

- Durable & stable: Built for high-load, continuous operation;

- Output purity: Final non-ferrous streams reach 98%–99.5% purity.

▶ Common Applications

- End-of-life vehicle (ELV) processing;

- WEEE recycling and home appliance dismantling;

- Industrial metal scrap treatment;

- Metal recovery from incinerator bottom ash (IBA).

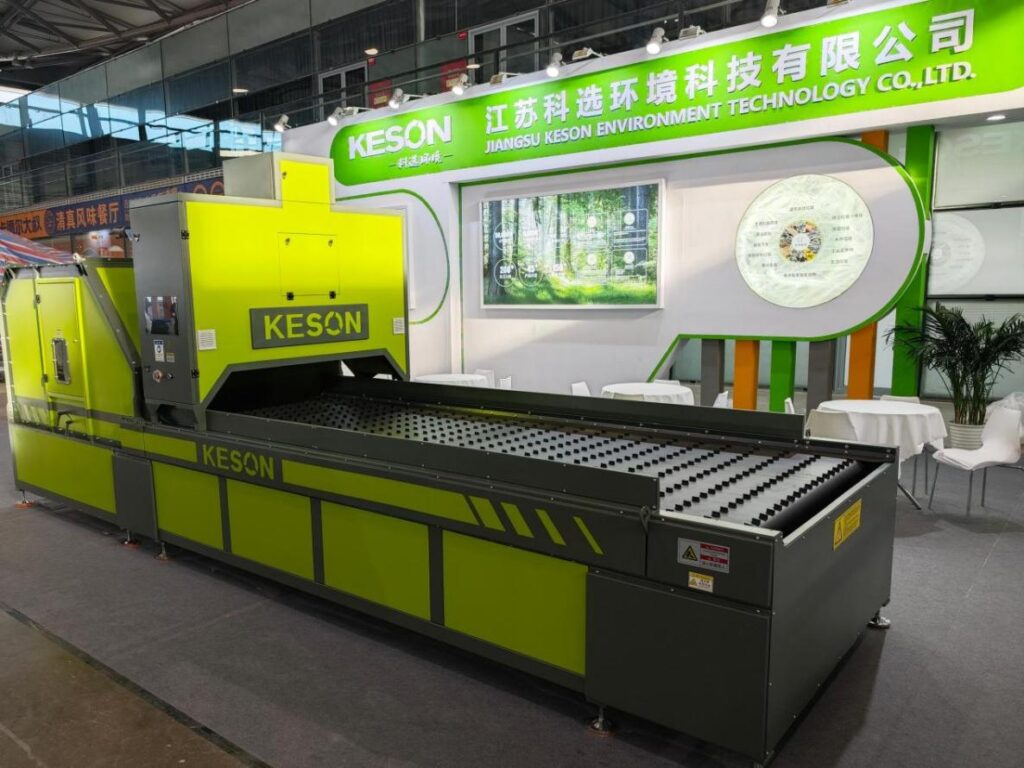

2. Intelligent Sorting System: AI-Driven Recognition for Maximum Value Recovery

Keson’s AI-Powered Sorting System combines advanced optics with machine learning algorithms to identify and sort various types of metal based on material, color, alloy, and surface conditions—taking fine separation to the next level.

▶ Key Technology Components

- Multispectral sensors: HD color cameras, NIR, and laser (LIBS);

- AI classification model: Identifies aluminum, copper, zinc, stainless steel, and more;

- Self-learning system: Continuously improves sorting performance;

- Smart control interface: Intuitive, touchscreen-based operation and data monitoring.

▶ Optional Features

- Multi-channel pneumatic ejectors;

- Auto-grading by material class;

- Integration with MES or SCADA platforms

3. Integrated Solution Benefits: Higher Recovery, Less Labor, More Profit

By integrating the Combined Eddy Current System with the AI Intelligent Sorting System, Keson enables clients to build full-spectrum sorting lines from coarse separation to fine sorting, drastically improving operational efficiency and profitability.

▶ Comparison Table

| Metric | Traditional Setup | Keson Integrated System |

| Ferrous Interference | Frequent, reduces ECS efficiency | Magnetic drum removes upfront |

| Non-Ferrous Purity | 85%–90% average | Up to ≥98.5% purity |

| Recovery Rate | Unstable, labor dependent | Stable, AI-optimized |

| O&M Costs | High labor, high downtime | Modular, smart diagnostics |

| Scalability | Difficult to integrate | MES/PLC compatible, plug & play |

4. Case Study: 35% Recovery Boost at a WEEE Recycling Facility

Client Profile: A large-scale electronics recycler processing over 40,000 tons of e-waste per year.

Keson Solution:

- 1 Combined Eddy Current System (magnetic drum + ECS);

- 2 AI-Powered Intelligent Sorting Units;

- Centralized monitoring and remote control system.

Results Achieved:

- +35% increase in total non-ferrous recovery;

- Copper and aluminum purity at 99.2% and 98.7%, respectively;

- Labor reduced by 3 operators per shift, saving approx. ¥600,000/year.

5. Green Vision: Turning Innovation Into Circular Economy Action

At Keson, we believe that high-efficiency metal separation is not just a business advantage, but a commitment to a more sustainable future. Our ongoing mission:

- Promote low-carbon, resource-saving solutions;

- Reduce the need for primary metal mining;

- Accelerate the global circular economy transition.

In many areas of circular economy, Keson has outstanding R&D strength and ranks among the best in the industry. Contact Keson to see how we can help you address the gap between solution supply and the fast-rising demand for solid waste with the latest technology.