The animation serves as a powerful illustration of how Eriez helps scrap yards maximise metal yield, reduce downtime, and improve profitability. Whether deployed individually or as part of a custom-engineered system, these solutions work together seamlessly. Lloyd Williams, Eriez-Europe Sales Director, explains that “Eriez doesn’t believe in a one-size-fits-all approach. Our specialists collaborate closely with scrap yard operators to understand their unique requirements and design tailored systems that deliver exceptional results.”

The animation opens with PokerSort®, showcasing its effectiveness in resolving one of scrap processing’s most persistent problems: removing long ferrous pieces from shredded material. Automating this critical step protects downstream equipment from jams and damage while streamlining material flow to eliminate costly interruptions and enhance throughput.

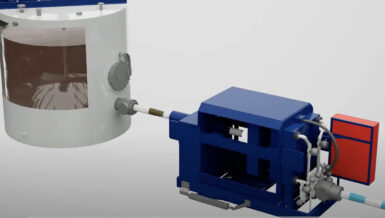

Next, the Double Pass P-Rex® Drum System takes over. Thanks to its robust dual-drum design and superior magnetic strength, it achieves industry-leading ferrous recovery. This boosts overall recovery and produces cleaner end products by liberating more nonferrous residue. The Shred1® Ballistic Separator follows. Efficiently separating premium, low-copper ferrous material from traditional #2 shred, it reduces manual sorting and increases material value. Finally, the Eriez Electromagnetic Scavenger Drum separates ferrous from nonferrous and debris, further increasing the grade of the shredded scrap.

Shifting to nonferrous recovery, the animation shows how Eriez solutions ensure reliable material handling and precise separation. Eriez Suspended Electromagnets remove lingering ferrous items from the nonferrous stream. The Eriez Dynamic Pulley Separator utilises an agitating magnetic field to enhance fine ferrous separation. Additionally, the Ultra High-Frequency Eddy Current Separator achieves unparalleled nonferrous recovery, producing a clean, market-ready mixed metals product with minimal residue.

The animation also features the Eriez Drum-in-Housing Magnetic System and the ST22 Eddy Current Separator, designed for the consistent recovery of medium-sized nonferrous materials. The LT2 Eddy Current Separator separates coarse nonferrous fractions, preceded by an Eriez Magnetic Pulley automatically removing the largest pieces of ferrous. Any oversized material passes through the trommel to complete the comprehensive recovery process.

“We created this animation to highlight how Eriez’ commitment to innovation, automation, and system integration delivers real benefits for scrap yard operations,” Williams detailed. “Reduced manual labour, increased productivity, enhanced equipment protection, and better metal recovery all contribute to a more lucrative, proficient, and future-ready facility.”

With a legacy of technical leadership and first-class support, Eriez helps scrap yards of all sizes realise a quick ROI. From single-line upgrades to fully integrated systems, Eriez delivers the expertise and proven technologies to keep operations running at peak performance.