Smarter Than Ever

At the heart of Max-AI® AIR lies one of the most sophisticated neural networks in the recycling sector. With over 300 material categories programmed into its “brain,” the AI can accurately identify even the most challenging materials—dirty, misclassified, or otherwise difficult to detect. For Max-AI AIR, these are no longer obstacles.

Trusted Mechanics, New Intelligence

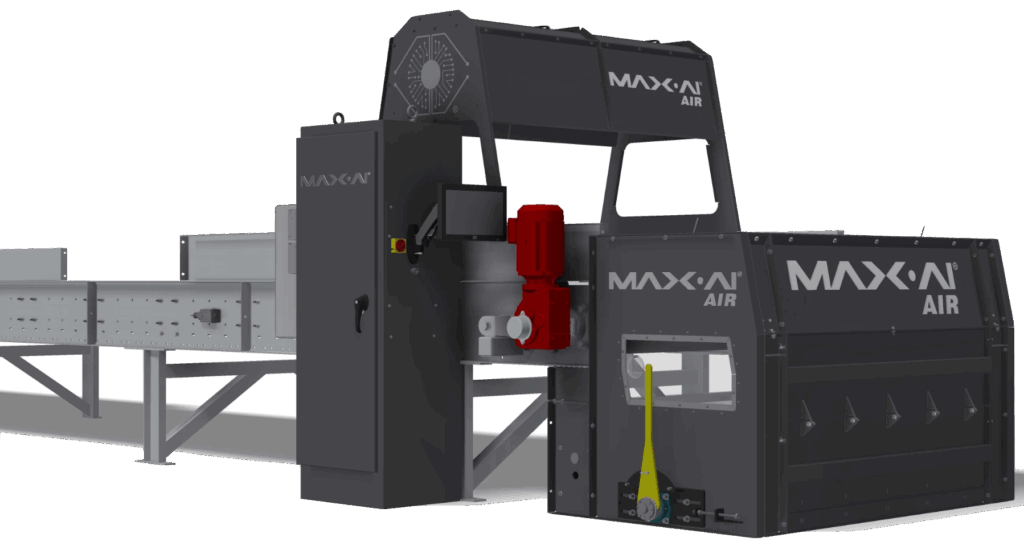

What sets Max-AI® AIR apart is the seamless integration of cutting-edge artificial intelligence with well-known and widely trusted air jet technology. These air jets, already a staple in optical sorting, are now guided by an unmatched level of intelligence, enabling lightning-fast, precise sorting with minimal error.

Critical Applications, Maximum Impact

The first units are being deployed in “Last Chance” lines and UBC (Used Beverage Can) clean-up applications—exactly where material recovery is most crucial and where value is often lost. Max-AI AIR steps in where other systems stop, providing a robust solution that improves recovery rates, reduces waste, and maximizes value from residual streams.

Designed for the Entire Industry

Max-AI® AIR is built for flexibility and performance across the board. Whether dealing with household waste, commercial recyclables, or specific material flows such as aluminum or PET, this system delivers consistent results. It’s not just an addition to the sorting line—it’s a strategic leap forward in building a more efficient and sustainable recycling operation.

Max-AI® AIR proves that the fusion of intelligent software and proven hardware is the key to unlocking the full potential of modern sorting facilities. In a world full of challenges, this is the technological breakthrough the industry has been waiting for.