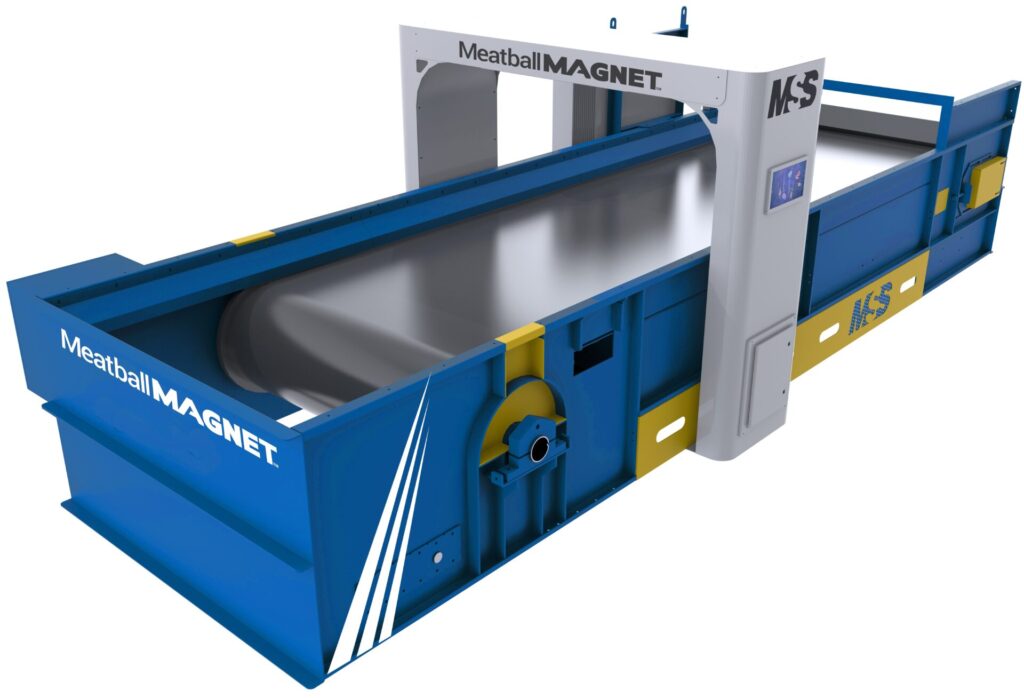

This advanced solution automates the separation of non-steel contaminants such as motors, transformers, alternators, etc. (“meatballs”) from shredded steel in auto-shredder facilities, which has traditionally been a challenge requiring manual labor.

The system employs AI detection algorithms to trigger electromagnets that sort the material as it travels at conveyor speeds of 250 feet per minute (FPM). The system’s deep learning neural networks consistently outperforms manual sorting, both in identification accuracy, as well as in handling individual items up to 25 pounds, even multiple items at one time.

“The Meatball Magnet™ represents a significant advancement in automated sorting technology for our scrap metal clients,” said Felix Hottenstein, Sales Director at MSS. “By leveraging similar technical approaches to other well-proven MSS sortation solutions, we are excited to help eliminate a difficult and dangerous manual sorting process while substantially improving Steel #1 quality and consistency.”

The Meatball Magnet™ is available in 32″, 48″, and 64″ machine widths, and is protected under multiple US Patents. For technical specifications and implementation details, please visit Meatball Magnet Brochure.