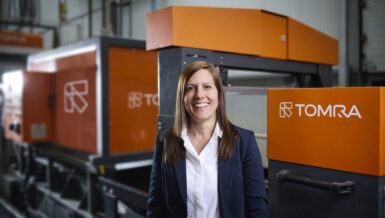

However, Greenpath Enterprises, a polymer recycler based in California, USA, set out to change that by developing a cap-to-cap recycling solution. By partnering with TOMRA Recycling Sorting, they successfully implemented a high-precision flake sorting system using TOMRA INNOSORT™ FLAKE, achieving purity levels of over 98%.

What is INNOSORT™ FLAKE?

INNOSORT™ FLAKE is TOMRA’s cutting-edge sorting technology, designed to simultaneously sort plastic flakes by polymer type and color with extreme accuracy. This advanced sorting system enables recyclers to:

– Process mixed polyolefin waste and recover high-purity fractions

– Achieve 98%+ purity in polyethylene (PE) and polypropylene (PP)

– Deliver high-quality post-consumer recycled (PCR) content

– Support closed-loop recycling for bottle caps and other applications

Today, Greenpath Enterprises now transforms a polyolefin mix into high-quality mono fractions, making cap-to-cap recycling a reality.

INNOSORT™ FLAKE Advantages at a glance:

· High-speed, automated flake sorting for large-scale processing

· Simultaneous detection of polymers and colors

· Sorts white opaque, natural, transparent and translucent flakes

· Sorts PET, PP, PE, PVC, PS, ABS, PA and more

Thanks to TOMRA’s sensor-based sorting technology, Greenpath Enterprises has taken a significant step toward sustainable, high-purity PCR production, creating new opportunities for recyclers looking to enhance material recovery and profitability.

Ready to upgrade your plastic recycling process?

Explore INNOSORT™ FLAKE: INNOSORT™ FLAKE

Learn more about the Greenpath Enterprises project: Closing the loop on bottle caps