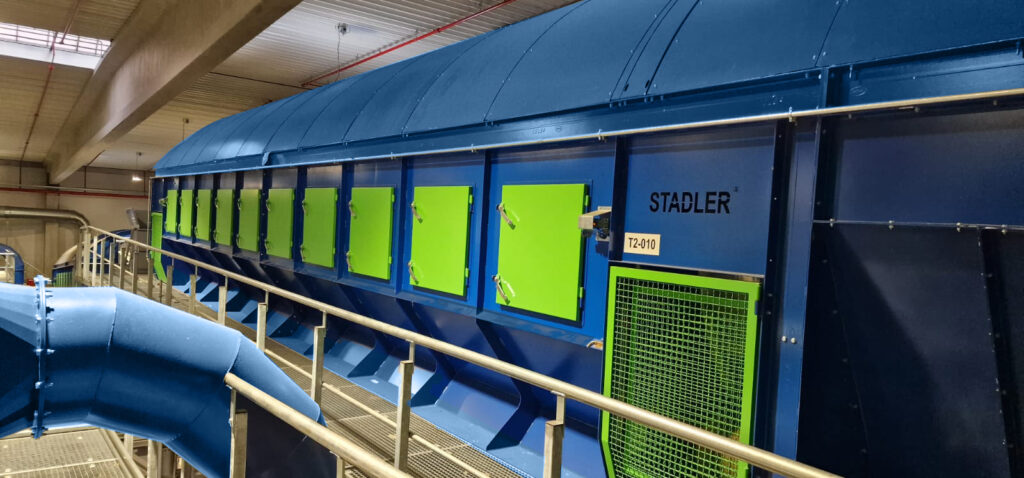

STADLER Anlagenbau GmbH, the globally active German company specialized in the planning, production and assembly of turnkey sorting plants, carried out the reconstruction of the Sortierkontor Nord (SKN) lightweight packaging facility in Bremen, Germany. After two fire incidents in 2022 severely damaged parts of the plant, SKN – operated as a joint venture between Nehlsen AG and PreZero Recycling Deutschland GmbH – tasked STADLER with the redesign and rebuild of the affected sections with a focus on future-ready safety, automation, and operational reliability.

The facility, originally designed and commissioned by STADLER in 2021, is one of Europe’s most modern sorting plants for lightweight packaging. It processes around 120,000 tons of material per year from the dual collection systems in Bremen and the surrounding federal states. With the rebuilt plant, commissioned in early 2025, SKN has restored its original throughput and significantly raised the bar in terms of fire protection, sorting stability and preparation for automated battery extraction – an increasingly critical challenge for the waste and recycling industry.

A redesigned facility built for safety, continuity and future performance

The reconstruction process was unlike a conventional plant build: around one-third of the machinery area was destroyed, and despite extensive preservation measures, further damage to standing equipment occurred during the complex insurance settlement process. STADLER integrated state-of-the-art sorting technology into the existing structure, while meeting significantly higher safety requirements.

“Fire incidents in light packaging plants tend to cause immense damage because hazardous components such as lithium-ion batteries are often concealed in the material stream,” explained Tom Schmitt, Sales Manager at STADLER. “In redesigning the Bremen facility, our priority was to ensure stable sorting performance while significantly increasing fire safety. This involved architectural changes, new system layouts, and the integration of technologies inspired by our latest projects.”

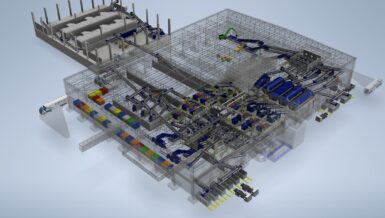

A central change in the new design was relocating the first classification steps – air separation, magnetic separation and 2D Flex sorting – into a hall structurally separated from the main machinery area. This spatial redesign increases fire protection by isolating these key critical early process stages, reducing the plant’s overall vulnerability to fire-related incidents. The addition of a second 100-cubic-meter fire extinguishing water tank, together with modern fire-protection systems including sprinklers and integrated fire suppression lines on equipment such as trommel screens, further enhances fire safety.

A modernized sorting process with enhanced automation and reduced manual intervention

The rebuilt sections of the plant now feature an optimized flow that reduces material bottlenecks and inefficiencies of the original setup. Three trommel screens, previously positioned in a single area and connected by long conveyor belts, are now arranged opposite each other for smoother, more accessible operation. Films – one of the highest-volume fractions – are now sorted fully automatically, with the option of integrating a third sorting stage in the future. SKN now produces transparent LDPE and mixed-film fractions with improved consistency and reduced manual handling.

The plant continues to deliver twelve high-purity mono-material fractions, including PP, PET, PE, PS, mixed polyolefins, paper-cardboard-carton, aluminum and additional composite materials. At the same time, the redesign enables the future integration of automated battery extraction technology similar to the system installed at PreZero’s Sollenau facility, which can detect and remove batteries.

“Restoring and securing the sorting capacity was our first priority,” said Benjamin Kreie, Managing Director of Sortierkontor Nord GmbH & Co.KG. “But together with STADLER, we went far beyond reconstruction. The modified sorting technology, the creation of more monitored fire sections, and the possibility to integrate battery extraction all raise the plant to a new level – safer, more robust, and better suited for current and future waste streams.”

“Achieving the highest possible level of fire protection – technically and organizationally – was crucial for us,” added Andreas Thiel, Managing Director of Sortierkontor Nord GmbH & Co. KG and Branch Manager at PreZero Recycling Deutschland GmbH. “The new plant structure, together with state-of-the-art sorting systems, allows us to operate with greater reliability and significantly reduced risk, ensuring the facility meets both operational and insurability requirements.”

Collaboration built on trust, experience and joint responsibility

STADLER’s long-standing relationships with Nehlsen and PreZero played an important role in the project. Having built previous plants for Nehlsen and collaborated on major recent projects with PreZero – including the Eitting and Sollenau facilities – the company brought both technical expertise and deep familiarity with the client organizations.

Reconstruction required close coordination between the three partners, external project management teams and insurance stakeholders. The process from incident to rebuild stretched over nearly three years, demanding persistence, detailed documentation, and joint decision-making at every step.

“During planning and installation, STADLER’s approach was communicative, open, and problem-focused, with a strong emphasis on keeping to the project schedule,” added Andreas Thiel. “Commissioning was more challenging due to coordinating subcontractors, which caused some delays. Despite this, the result was a high-performance facility capable of reliably meeting its sorting volumes.”

A safer, more resilient plant ready for the future

With the completion of the SKN reconstruction, Bremen once again hosts one of Europe’s most advanced light packaging sorting plants, now rebuilt as a stronger, safer, and more forward-looking facility. It demonstrates how modern recycling infrastructure can evolve to meet rising safety demands while maintaining high throughput and output quality.

“Fire risks in light packaging sorting can never be completely eliminated,” concluded Wolfgang Köser, STADLER Sales Director for Germany, Austria and Switzerland. “With the measures implemented in Bremen – including structurally separated classification halls, monitored fire zones, sprinklers and integrated fire suppression systems – the plant now operates at significantly lower risk and with much greater resilience. This project shows what can be achieved when long-term partners work together to rebuild not only what was lost, but to create a facility ready for current and future challenges.”