In Norway, all producers and importers of beverages, in either cans or non-refillable bottles (PET), can register their products in the deposit system.

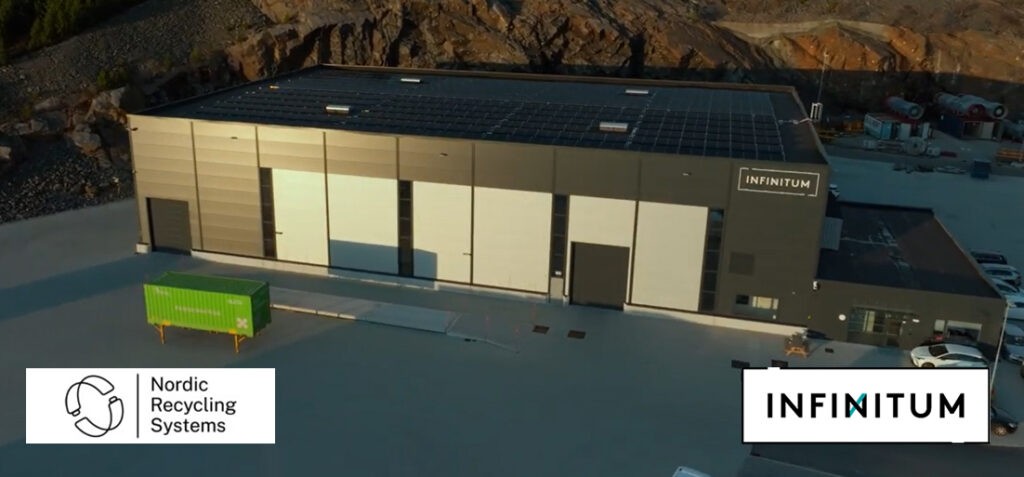

In November 2024, Infinitum AS opened a brand-new sorting plant at Skurve, on the southwest coast of Norway.

The facility is the result of a collaboration between Infinitum and Nordic Recycling Systems (NRS), a full-service supplier of technical solutions for handling and recycling of used beverage containers. Both companies share a common commitment to innovation and sustainability in recycling.

A State-Of-The-Art Facility

Nordic Recycling Systems & Infinitum wanted to make this new sorting plant the world’s most advanced for used beverage containers with cutting-edge technologies. Nordic Recycling System chose Pellenc ST to supply the most advanced optical sorters and placed its trust in Pellenc ST, particularly because of the quality of its equipment and services.

In practical terms, the sorting centre process more than 14000 tonnes of PET bottles and beverage cans every year. The plant is fitted with state-of-the-art equipment to ensure that the waste is processed correctly: A patented robot bag opening system with self-learning camera systems with artificial intelligence guarantees that the bags are opened completely, a unique air transport system also guarantees low operating costs as well as a clean environment. The plant is also equipped with the most advanced label removing system ensuring loose labels are collected in big bags.

Concerning optical sorting, a COMPACT+™ sorter uses Infra-red spectroscopy to recover all PET bottles and Vision spectroscopy to separate them by colour with above 99% purity for the clear PET fraction. Once sorted, PET bottles (around 70%) and aluminium cans (around 20%) are sent to their own recycling channels for a second life.

By combining advanced sorting technologies with artificial intelligence, the plant is positioned as one of the most advanced in the industry and helps to make the economy ever more circular.

To know more about this project, watch the video here: