A technological leap without a complete rebuild

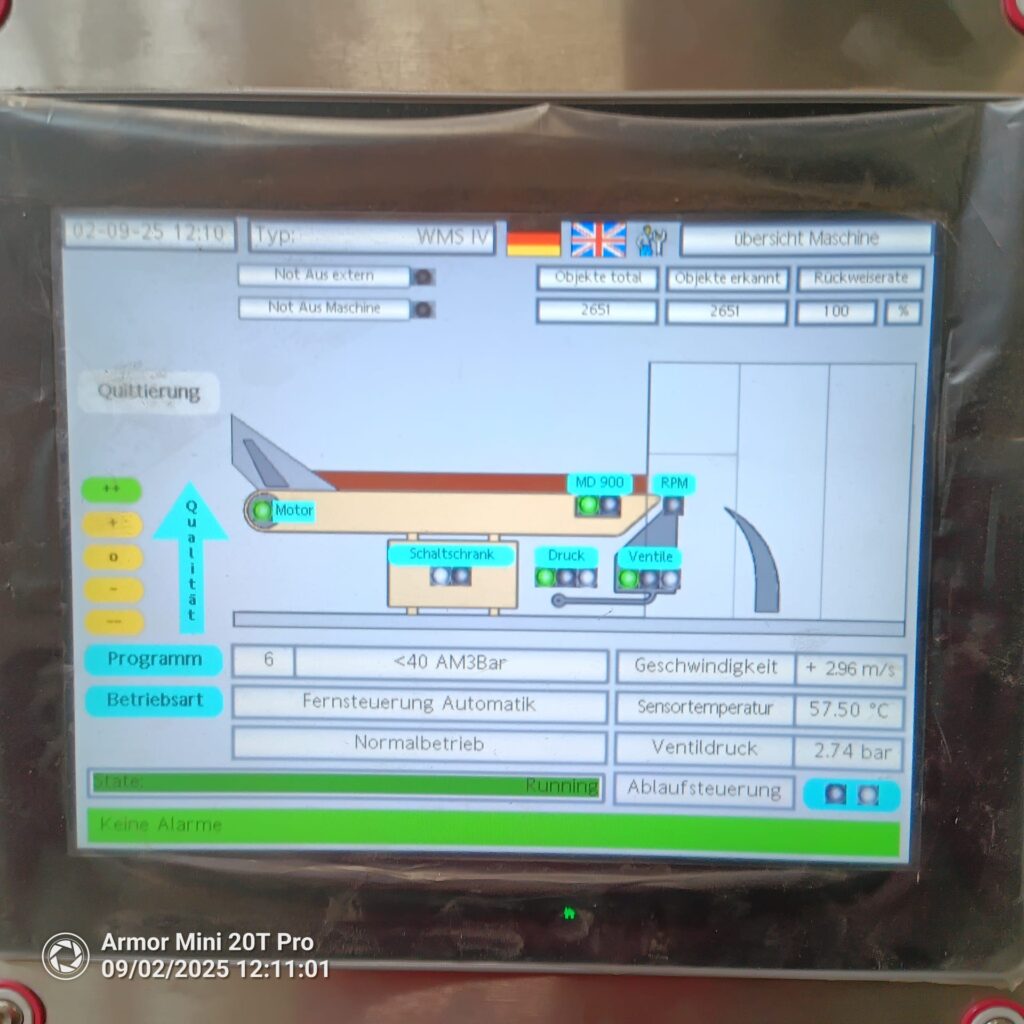

Instead of replacing old systems, Sense2Sort and WMS pursues a strategy of targeted modernization: core components are upgraded, while the basic structure remains unchanged. At Thommen AG, the latest update included three key modules:

• a completely redesigned valve bank (blowing unit)

• a state-of-the-art PLC

• a modern, user-friendly control terminal

This makes the system, which has been running reliably since 2009, fit for the next ten years – even under full three-shift operation.

New Blowing unit installed in existing MD900 New user-friendly operating software

More efficiency, less energy

The revolutionary valve bank is the true centrepiece:

• Efficiency boost from 27% to 49%

• Halved input pressure: only 2 bar instead of 4 bar – with the same output

• Extended lifetime: valves now last up to six years

• Greater clarity: simplified maintenance and faster valve replacement

Compressed air management has also been completely rethought. System fluctuations were reduced by 50%, enabling more precise adjustments and additional energy savings.

Voices from the field

“With the upgrade to the nozzle bank, we are going far beyond today’s state of the art. The technology has proven itself even in the harsh shredder environment – and with updates, the system remains at top level over the long term,” explains Peter Kremer, technical manager of the Thommen AG group.

Thommen AG is using his MD900 sorters based on inductive technology for the first sorting step of all metals post ECS accept material as well as for a second sorting step to create clean stainless-steel from all metal fraction out of the first MD900. With amazing sorting results.

Stainless steel fraction >98 purity Non-Metal fraction >99% purity

A signal to the industry

The progress is striking while systems from 1998–2002 required 8–10 bar, today only 2–3 bar are needed in heavy-duty applications like the stainless-steel at Thommen, and just 0.5 bar for lightweight materials such as PET. The result: dramatically lower compressed air consumption while increasing overall performance.

Conclusion

With Thommen AG as a long-term partner, WMS as the inventor of the Air Management System, demonstrates how modernized technology not only extends the life of existing systems but elevates them to a new level of efficiency. A concept with impact and a clear signal for the future of sensor-based sorting.