This innovative facility transforms low-value waste plastics into high-value chemicals such as propylene and ethylene, creating valuable feedstock for the chemical industry while significantly reducing landfill and incineration.

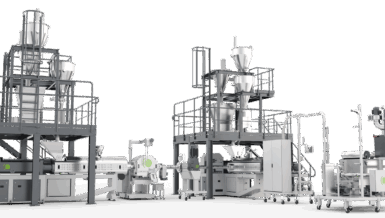

At the heart of the operation are six Harden SG2200RP single-shaft shredders, running stably and efficiently onsite. Each unit processes up to 6 tons per hour, ensuring a constant supply of uniformly sized material for downstream processing.

Converting Challenging Waste into Valuable Resources

The plant is designed to handle a wide variety of mixed waste plastics—including agricultural film, paper mill waste, municipal waste, and other low-value plastics. Input material, typically sized between 100–400 mm, is shredded to a precise ≤30 mm output size, perfectly suited for advanced chemical recycling.

Why Harden SG2200RP Shredders?

- Integrated screening system for output sizes down to 20 mm when needed

- Four-edge rotatable blades to reduce cost per ton and extend wear life

- Variable torque drive system that adapts to diverse materials

- Quick-adjustable cutting gap enabling throughput up to 15 t/h (depending on material and input size)

High-Performance Recycling with Lower Environmental Impact

The combination of advanced shredding technology and chemical recycling capacity allows the facility to reclaim plastics previously considered too contaminated or degraded for reuse. By recycling instead of discarding, the plant achieves major water and energy savings, reduces greenhouse gas emissions, and produces high-purity chemical outputs ready for reintegration into manufacturing.

With its scale, efficiency, and adaptability, this project demonstrates the potential of industrial innovation to tackle one of the most pressing environmental challenges—plastic waste—while generating valuable products for a more sustainable future.

Contact: info@hardenmachinery.com