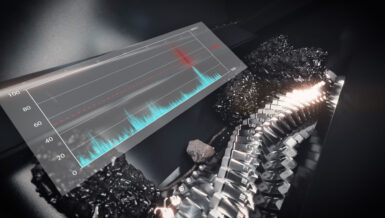

The newly commissioned facility features a fully integrated, high-capacity system engineered and delivered, turnkey, by WENDT. At the heart of the system is WENDT’s renowned M6090 Shredder, a modular solution designed for maximum throughput and efficiency, powered by an AC motor with variable frequency drive to optimize energy use and performance. The system also includes an infeed conveyor, the WENDT EZR PreShredder, and a comprehensive downstream sorting system.

Designed specifically for the aluminum sector, WENDT’s system can process a wide range of aluminum grades and product types, including baled and loose taint/tabor, production scrap, and used beverage cans (UBCs), among others. Its flexible shredding and sorting configuration allows Novelis to adapt to evolving feedstock streams while maintaining high recovery rates and product purity.

“We are proud to support Novelis in their vision to advance aluminum as the material of choice with circular solutions,” said Tom Wendt, President of WENDT CORPORATION. “This project is one of the most advanced and comprehensive aluminum processing systems we’ve delivered. It highlights the strength of our team and our ability to guide customers through the complexities of large-scale aluminum recycling projects, helping them achieve both their sustainability and operational goals.”