Kibag Kies Weinfelden AG modernised its concrete and recycling plant in the south-east of the town. The joint venture between Kibag AG and TIT Imhof AG under the name Baustoff Recycling Thurgau (BRT) AG aims to close the material cycles in the regional construction sector. Using state-of-the-art technology, mineral materials (contaminated and uncontaminated) are processed and the reusable components are recovered as high-quality building materials. The resulting building materials are used for the production of concrete or as gravel mixtures on regional road and civil engineering construction sites.

State-of-the-art wet-mechanical processing plant

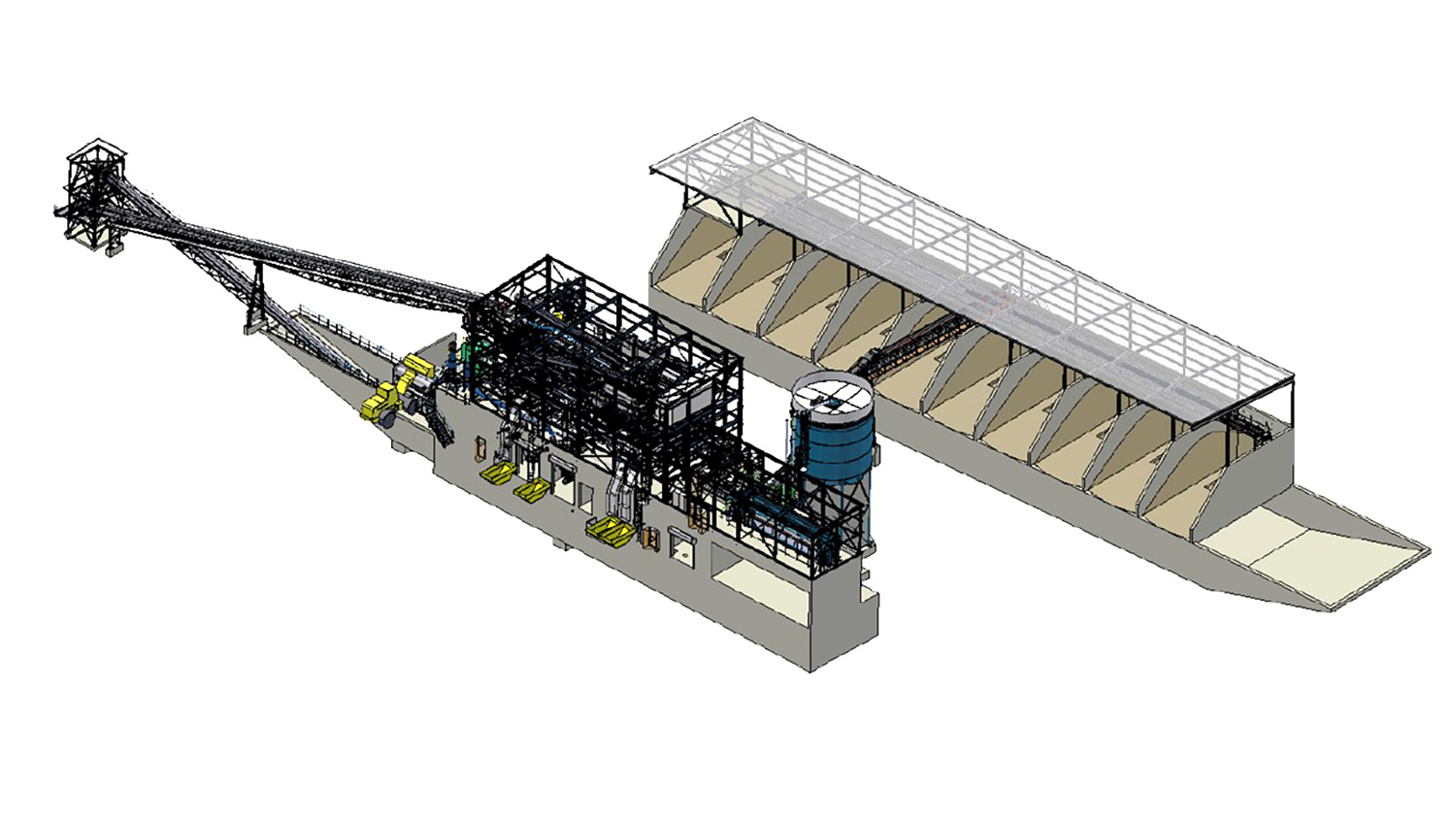

The new wet-mechanical processing plant is the central collection point for mineral waste from the canton of Thurgau and neighbouring cantons and is state of the art. The ability to accept mineral waste by rail and remove gravel again can greatly improve the environmental compatibility of transport. As the general contractor, Frei Fördertechnik AG developed the process engineering solution for processing the raw materials according to the desired target products and in the corresponding quality. It was also heavily involved in the planning and execution of the steel construction.

The plant concept was customised to the client’s requirements and the conditions on site. The aim was always to maximise operational efficiency. The steel structure has external dimensions of 51 x 16 m and extends over three storeys, on which material, water and technology are processed. Material transport on the site is primarily carried out using conveyor belts so that wheel loader hours can be reduced.

Closing the material cycles

The new processing technology results in a much better quality of the recycling material, says Martin Feldmann, Managing Director of BRT AG. “Fines, which previously reduced the quality and caused large fluctuations, can be efficiently removed with wet mechanical processing. By closing the material cycles in this way, we are effectively combating the scarcity of resources. The fact that processing and reuse in concrete production take place on the same site means that transport can also be reduced. The Swiss construction industry continues to grow – which makes it all the more important to utilise the available primary and secondary raw materials as efficiently as possible. We want to make our contribution to this.”

Opening of the complete Baustoff-City in autumn 2024

The complete Baustoff-City opened in autumn 2024. The site will then include the wet-mechanical processing plant (operations began in autumn 2023), a recycling site for dry processing and a concrete plant that can recycle recycled material.

Scope of delivery of Frei Fördertechnik AG – complete system from a single source

- Consulting, engineering, planning, realisation, installation and commissioning

- Process engineering plant construction for a turnkey system

- Material feeding

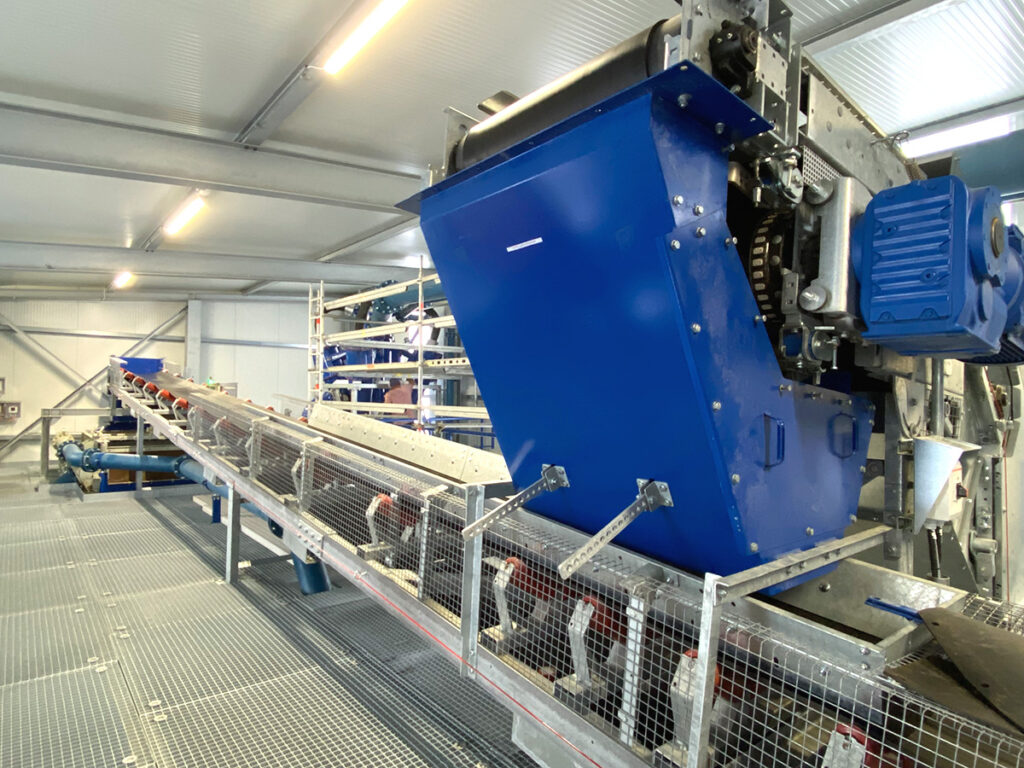

- Material washing and gravel processing

- Impact crusher

- Conveying technology

- Sand processing

- Material boxes

- Dedusting system

- Silo and dosing system

- Water treatment plant – planning support from Frei Fördertechnik

- Removal of foreign matter / classification

- Pipeline construction for treatment plant

- Steel construction with building shell (without concrete construction)

- Control system and software – planning support from Frei Fördertechnik

- Spare and wear parts

ModuFlex.FFAG – Modular plant construction

Benefit from the advantages of modular plant construction that can be perfectly customised to your specific requirements. With the flexible expansion of six modules, we offer you an individual solution that can be optimised step by step – from improving material quality to increasing the purity of the end products.

Optimise your processes with a solution that sets the highest standards in terms of both technology and flexibility. Efficient removal of unwanted components for improved material quality and unbeatable purity of the end products.