ITS approaches each project by first defining material characteristics, throughput targets and site constraints. From that brief the company engineers a complete feed solution that typically includes: a loading conveyor sized for piece geometry and elevation; a controlled feed arrangement to the shredder rotor; a discharge conveyor matched to downstream equipment; and safety interlocks and enclosures that meet applicable European standards. Because ITS designs and produces every mechanical component, the company can adapt belt widths, speeds, hopper geometries, tipper capacities and guard layouts to the customer’s exact needs.

Here are some recent success stories, of ITS plants with complete conveyor systems, completely designed and produced by ITS.

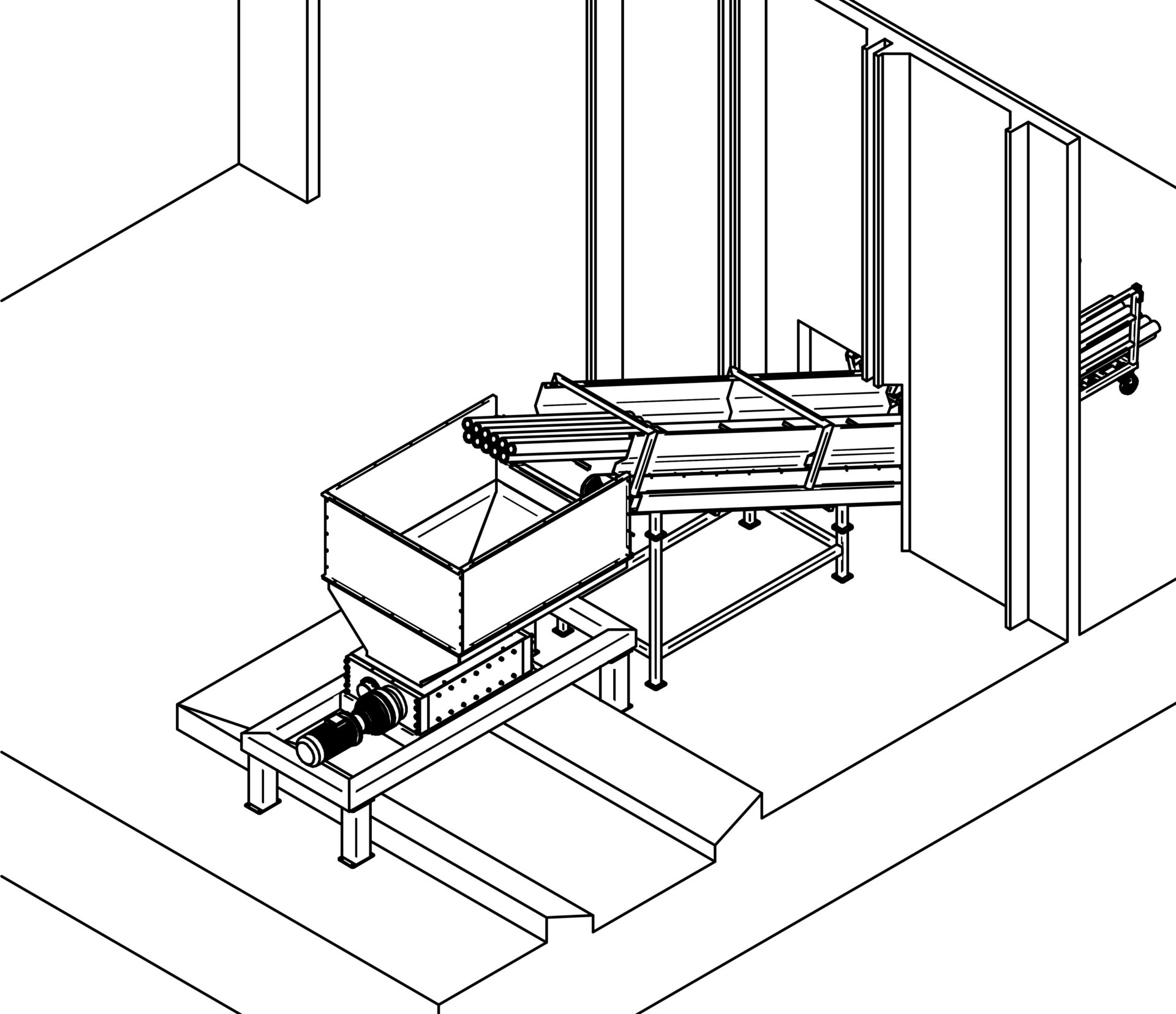

Case study 1: Bottle recycling line

The bottle recycling installation features a 3 metre high loading conveyor, an ITS 1250×900 EP twin shaft shredder and a discharge conveyor exceeding 4 meters. This configuration demonstrates ITS’s ability to handle mixed, bulky feedstocks by:

- Controlling feed to reduce bridging and rotor overload;

- Sizing discharge elevation to feed downstream separation or storage systems without additional transfer stations;

- Balancing throughput between conveyor capacity and shredder sizing to maintain continuous operation.

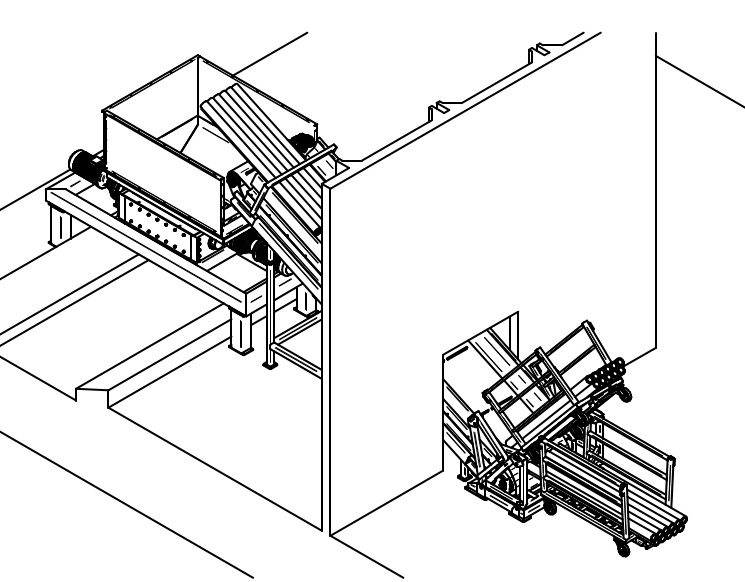

Case study 2: Cardboard recycling for a cardboard manufacturing facility

Here ITS delivered a system composed entirely of ITS designed modules:

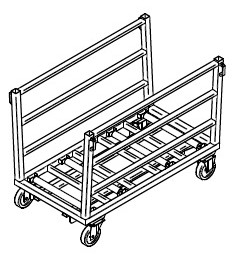

- Loading cart for variable carton and cardboard sheets and cores.

- Protective fenced automated loading area with an electronic safety microswitch on the access door so the cycle only operates when the door is closed, and ensuring compliance with European safety requirements.

- Automatic custom tipper to transfer cart contents into the safety zone and onto the conveyor.

- Transport conveyor that feeds the hopper and the ITS 1250×900 E shredder for case and carton reduction.

This solution reduces manual handling, improves operator safety and standardizes feed quality into the shredder.

Why choose an OEM that manufactures conveyors and shredders

Single source engineering reduces integration risk: mechanical, electrical and safety systems are designed to work together from the start. ITS’s in house production enables:

- Faster customization of belt widths, hopper shapes and tipper interfaces;

- Simplified commissioning because control logic and safety interlocks are pre integrated;

- Easier spare parts management and consistent service support.

For companies evaluating size reduction technology, ITS offers a compelling proposition: customizable, in house designed conveyor systems integrated with proven shredders such as the ITS 1250×900 E/EP, delivered as turnkey lines that prioritize throughput, safety and downstream compatibility. Recent installations for bottle and cardboard recycling illustrate how ITS adapts its modules to meet diverse material and regulatory demands while keeping the entire system under single vendor responsibility.