Plastic recycling is more relevant than ever, because it is one of the most widely used materials today: durable, lightweight, and cost-efficient for both consumer and industrial use. Its popularity, however, makes responsible handling essential after its first use. Recycling gives plastic a new life and helps prevent it from ending up in landfills, being burned for energy, or breaking down into microplastics in nature.

Because plastic recycling depends on markets, local regulations, and collective action, everyone plays a role, whether you are a designer or a consumer of plastic products or a waste collector, efficient recycling starts with all of us. And every successful recycling process begins with a smooth and reliable material infeed – the key to ensuring continuous flow and optimal efficiency right from the start.

Efficiency Meets Sustainability in Plastic Recycling

Balancing efficiency and sustainability are one of the biggest challenges recyclers face today. As demand for recycled plastic grows and regulations tighten, the industry is turning to automation, higher capacity, and smarter processes to recycle more plastic, faster and with less environmental impact.

Yet recyclers still face challenges such as turbulent markets, competition for raw materials, and labor shortages in many regions. Beyond regulations, incentives are needed to make recycled plastics more competitive with virgin materials. The key question remains: how can plastics be recycled profitably?

We at Cross Wrap do our part so that recycling would be more efficient, reliable and economically worthwhile for plastic recycling and processing companies. Cross Wrap at the forefront of providing automated solutions designed to improve plastic recycling processes.

Wire Removal in Plastic Recycling: Which Method Fits Your Process Best?

Plastic must be sorted and recycled by type to preserve its value. After collecting, plastics like PET, HDPE, and LDPE are sorted, washed, and prepared for reuse. Many facilities receive their materials in compressed square bales for easier transport, making bale opening the essential first step in the recycling process.

At the start of your recycling or production line, baled material needs to be opened, and wires removed to create a smooth and consistent material flow. There are several most common ways to do this, and each method has its strengths and challenges, but with the right combination, you can achieve the best results for your operation.

There are three main ways to handle this step, each with its own strengths and challenges:

Manual Wire Cutting – Simple and low-cost, but labor-intensive and risky for operators.

Shredding – Automates the process by crushing bales with wires included, but increases maintenance costs.

Automated Dewiring – The safest and most efficient option, cutting and coiling wires automatically for cleaner material flow and smoother downstream processing.

Cross Wrap helps to improve recycling plant efficiency

“Customers report up to 50% less wear and tear on shredders when using Dewiring solutions.”

Cross Wrap pioneered automated Bale Dewiring for plastic recycling in 2017, setting the industry standard. The dewiring solution is an infeed, bale opening and wire cutting solution by nature.

Let´s look at the process start closer!

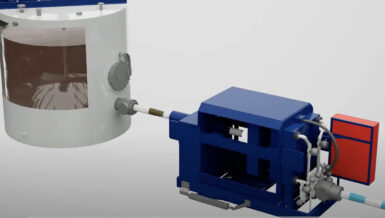

After waste bales arrive at the recycling facility, the baled material must be fed into the process and opened to get a loose material flow, depending on customer´s needs and volumes, the plastic bales will be placed onto infeeding conveyor or directly into the Dewiring unit. The fully automated process cuts, removes and coils the metal wires for easy handling. Once dewired, the bale opens into slices, allowing shredders or bale breakers to handle the material for the next process steps.

Installed before a shredder or bale breaker, the Dewiring Machine ensures smoother material flow, improved safety, and lower maintenance costs.

Built on a solution-oriented approach, every machine is tailored to meet customer-specific needs and operational goals. Designed for both horizontal and cross-wired bales, the system can include a bale turning unit for added flexibility, making it ideal for facilities handling mixed bale types.

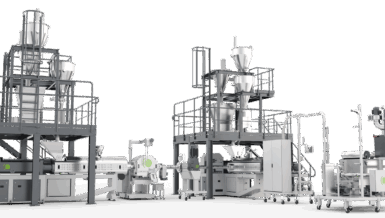

Cross Wrap chain conveyors ensure baled material moves efficiently through the recycling line. Chain belt conveyors are ideal for plastic recycling. Fully automated and customizable, multiple units can be linked to create a seamless infeed system.

To further optimize your process, Cross Wrap offers smart add-ons like the Bale Slice Breaker, which loosens bale slices for even smoother flow, and the Coil Shredder, which crushes a metal coils for cleaner recycling and higher material value.

Conclusion

Cross Wrap continues to lead the way worldwide in safer, smarter, and more efficient bale handling solutions. Since the founding of Cross Wrap, the company built its business on flexibility and a solution-oriented mindset. Cross Wrap takes pride in meeting its customers where they are and understanding their unique challenges in plastic recycling. Cross Wrap´s engineers don’t design products in isolation; instead, we collaborate closely with our clients to create solutions that address their specific needs.

For more information, visit www.crosswrap.com or contact our team for tailored solutions that fit your plant’s specific needs

Written by Jenni Kaurola