Plastics expertise across the board

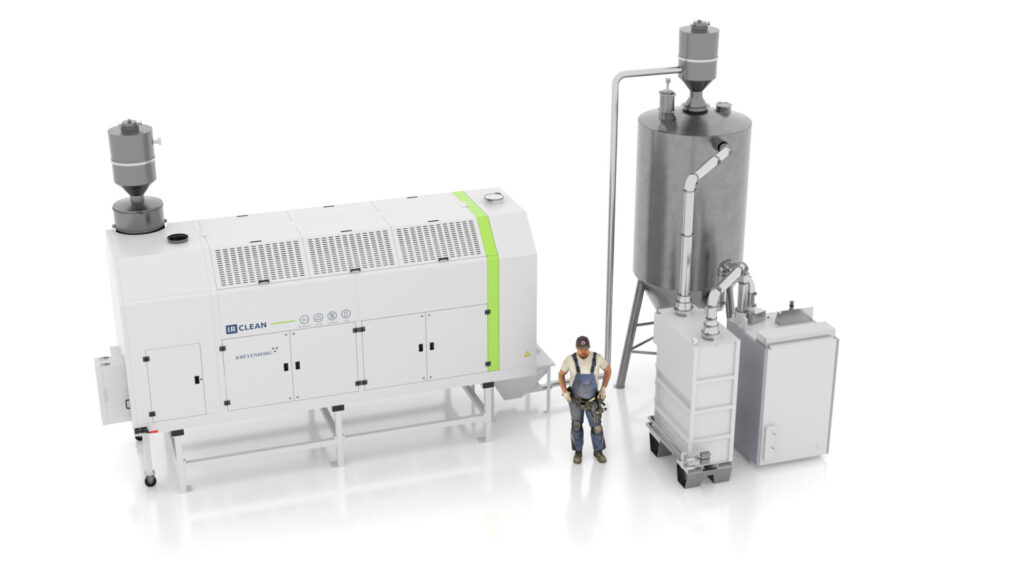

Kreyenborg, the plastics specialist from Germany, will be demonstrating both a continuous system and a batch version of the infrared rotary drum (IRD) at the K trade fair. To demonstrate the IRD a large monitor that provides a view into the interior, showing how the material in the rotating drum behaves under infrared light. With mixers, special silos and extruder feeding systems, the plant manufacturer will be demonstrating its broad and decades-long expertise in the handling of bulk materials. Easily and poorly free-flowing or sensitive products have specific characteristics: they stick to each other, contain excess moisture, are not homogeneous, form bridges during removal or fail to flow properly. Such challenges in bulk material handling are business as usual at Kreyenborg, such as in the construction of special silos or mixing and feeding systems. and Kreyenborg’s presentations are an integral part of every K trade fair.

Specialist in plastics recycling

Kreyenborg specializes in the recycling of post-consumer recycled PET flakes (rPET) and has developed the IRClean system in addition to the IRD’s classic crystallization and drying. rPET flakes are heated from the inside to the outside in just a few minutes. The decontamination performance of the IR Clean achieves a cleaning efficiency of over 95% and thus meets both the EU/EFSA and the US-FDA criteria and up to 100 percent of the treated material can then be used for food packaging.

Kreyenborg can now also draw on a wealth of experience in the odor reduction of post-consumer plastics in the polyolefin sector. The PP or PE recyclates often absorb intense odors from cleaning agents, detergents, chemicals, cosmetics or fuels, and therefore cannot be processed further. Kreyenborg has developed a simple and fast process for deodorizing the regrind before or after the extrusion process (IR-Fresh system), which is also suitable as a retrofit solution for extrusion lines. Process times are significantly shortened and a highquality plastic recyclate is produced.

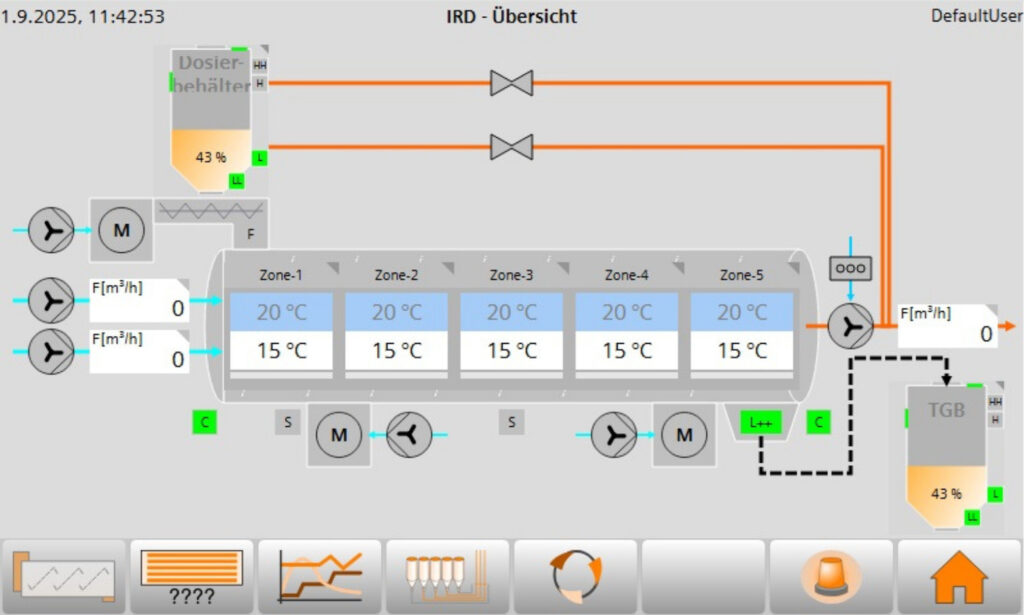

NEWQ visual control software

Kreyenborg will present a preview of a completely new control system for the IRD. The 7- and 15-inch monitors have been given a graphical user interface and make the software much more user-friendly. Due to the visual structure, the software offers a better overview and easy control. In addition, some steps are no longer necessary. Greater transparency is now possible, allowing the user to make more accurate and faster decisions in the production process on the machine. The new panel with the graphical software will be part of every new IRD system in the future.

Focus on energy saving in the development of new systems

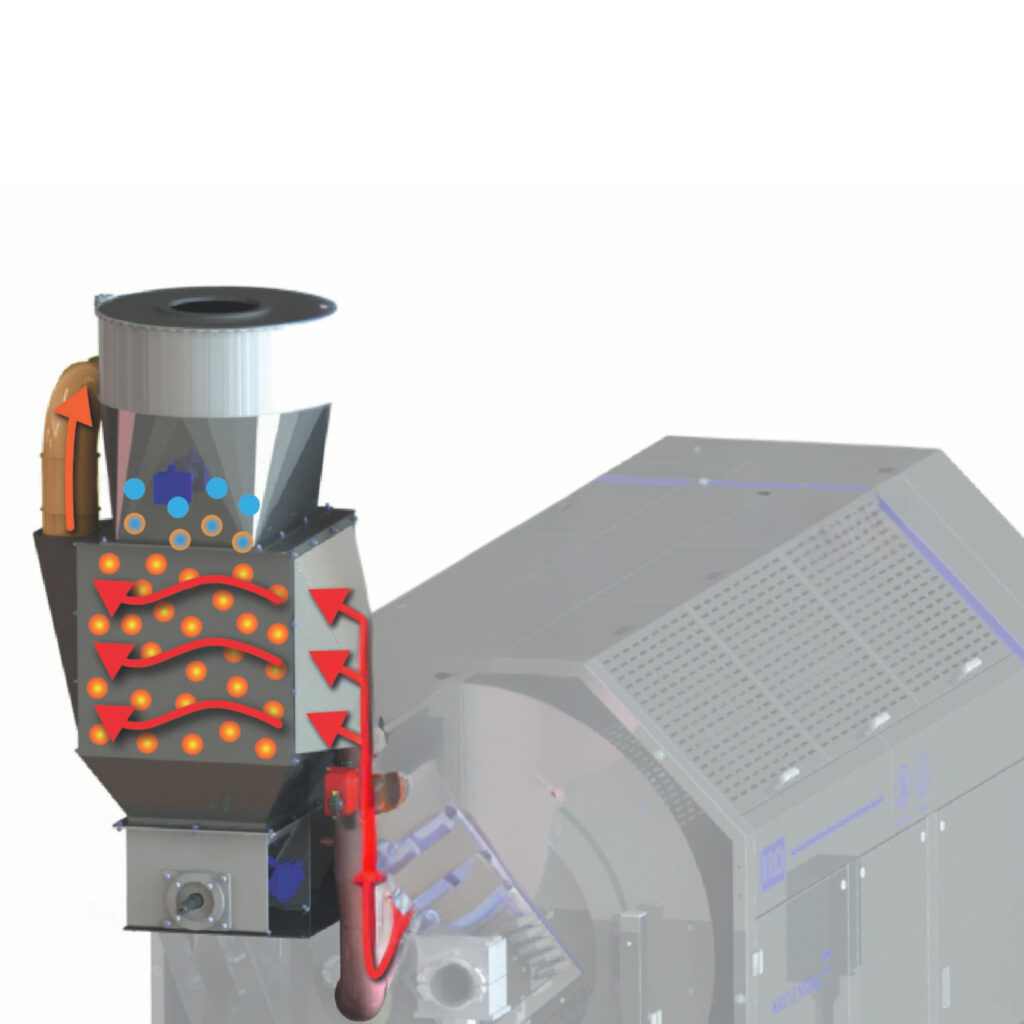

For the sustainable use of heat from infrared technology, Kreyenborg offers a retrofit solution for the IRD, the Eco-Booster. Heat from the infrared rotary tube is used to preheat the raw material waiting to be supplied. This can save up to 10 percent of energy use or increase the throughput of the material by up to 20 percent. The system can thus pay for itself after about one year. Kreyenborg sees the development of such solutions as an important contribution to energy efficiency and sustainability in plant engineering and to the circular economy in general.