Ready for a revolution in mechanical recycling – with this slogan, Lindner presented its revolutionary cleaning process, Flexloop, at the start of the K trade fair on 8 October. The origins of this development go back to the last K show, which is when the first discussions were held between Lindner and Procter & Gamble. These initial ideas turned into concrete plans, which were followed by intense negotiations. Eventually, Lindner obtained the exclusive licensing rights to the technology developed by Procter & Gamble – with the mutually agreed goal of establishing an industrially scalable recycling process.

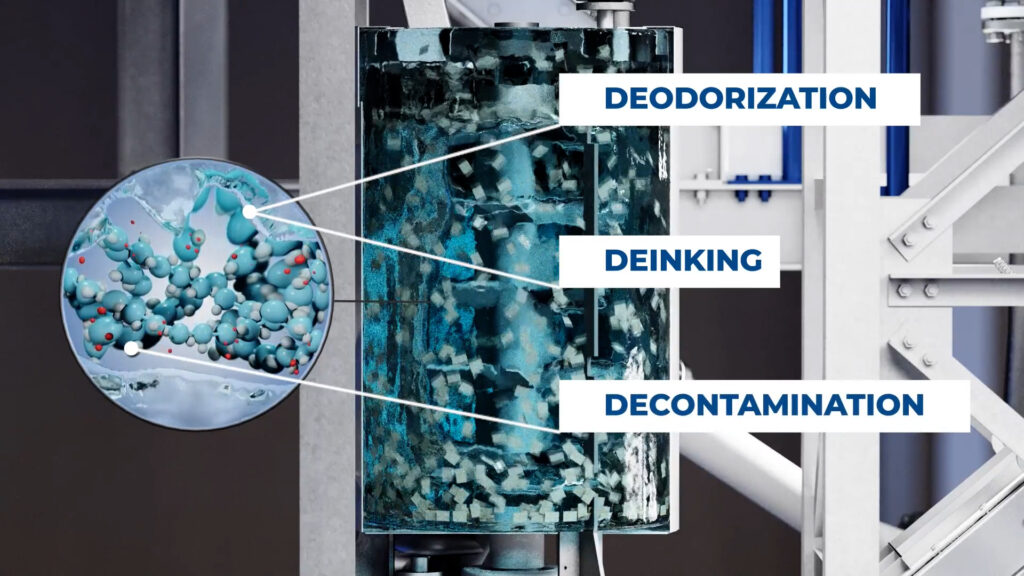

“We have always wanted to advance mechanical recycling,” says Michael Lackner, Managing Director of the Lindner Group. “For us, Flexloop is a logical and necessary development in mechanical recycling and an extension of cold and hot washing.” Flexloop follows preliminary mechanical cleaning and provides a solvent-based extraction step. In this step, NIAS (non-intentionally added substances) such as pesticides, phthalates, dioxins and organic residues are also extracted and taken away along with odours, adhesives and printing inks. “This mechanical recycling technology gives recyclers a valuable tool and helps them produce recyclates for sophisticated applications, using the mechanical recycling technology they know and trust,” says Lackner.

Lee Ellen Drechsler, Senior Vice President of Research & Development at P&G, adds:

“We foresee a growing demand for high-quality recycled resin that is suitable for a wide range of flexible film applications, so we are excited for the introduction of Flexloop, an innovation our researchers developed as an option for upcycling a wide range of plastic materials through mechanical solvent extraction. The license of this plastic-to-plastic cleaning technology to Lindner is consistent with our corporate commitment to bring to scale technologies that can help address significant environmental challenges including the reduction of plastic waste and achieving a circular economy for materials.”

“The difficulty of obtaining high-quality, clean recyclate is a particular problem when handling post-consumer waste and for mixed plastics from domestic and commercial collections,” says Yannick Stanau, Business Development Manager at Lindner Washtech. “During collection, plastics of all different types and origins are mixed together – and they can absorb substances that you wouldn’t expect to find in this material – this is generally referred to as contamination. For instance, food packaging could come into direct contact during collection with packaging that was not originally intended for food – NIAS can diffuse into the polymer and be transferred,” Yannick explains. Recyclate made from post-consumer plastics is currently mostly only used in less advanced applications such as park benches or rubbish bags. Chemical recycling is frequently used as a solution for post-consumer plastics, however, the high investment and energy costs mean that this route holds limited commercial appeal.

“With Flexloop, we have found a solution for this problem,” says Stanau. Flexloop can be viewed as an extension of the mechanical recycling process. The additional solvent-based cleaning step makes it possible to extract NIAS, odours, adhesives and printing inks out of polymers, without attacking their structure. This results in a consistent recyclate quality, which can even be suitable for sensitive applications in cosmetics and personal care. Recyclates obtained this way not only comply with legal requirements, they also meet the often much stricter specifications of many brand manufacturers.

Gian De Belder, Technical Director, Packaging Sustainability at P&G, is excited for the launch and the new opportunities that this will bring recyclers worldwide. “It’s great to see this cleaning technology come to life. Flexloop is particularly important for a wide range of feedstocks, specifically packaging and agricultural films. The technology allows us to get a step closer to make film packaging fully circular by closing the loop, for example by producing high-quality rPE film grades that can be safely used in a new generation of film packaging aimed at sensitive packaging applications.”

In view of its modularity, the Flexloop unit can be integrated in any Lindner washing and recycling line so that recyclers can use the existing infrastructure and incorporate Flexloop in the existing processes. The capital expenditure and operating expenses, compared to chemical recycling, are low. De Belder continues: “The beauty of the technology is that target users are the mechanical recyclers who have an interest in upgrading the quality of their recycled resin – and they can do this simply by retrofitting their existing washing lines.”

With their Flexloop technology, Lindner and Procter & Gamble are presenting a pivotal innovation in mechanical recycling – a technology that is cost-efficient and scalable. It fulfils the increasing requirements of brand manufacturers and also gives recycling companies access to a new product portfolio and new sales markets.

Flexloop is the name of the new mechanical recycling technology that Lindner is presenting to recyclers at K 2025 in collaboration with P&G. With the help of a solvent-based extraction process, polymer chains are reliably cleaned from contaminants (NIAS), odours, adhesives and printing inks – and this with consistent purity, so that recyclates can also be used for sensitive packaging, e.g. in the cosmetics or hygiene sector.