A multi-stage treatment is required to eliminate these odours sufficiently, allowing the pellets to be processed into high-quality end products for applications in industries such as packaging, automotive, and consumer goods.

Next Generation Recyclingmaschinen GmbH (NGR) and Kreyenborg GmbH & Co. KG have announced a strategic collaboration to sustainably enhance the quality of the recycled product through innovative technologies aimed at reducing odours and emissions.

This partnership combines NGR’s know-how in efficient recycling of plastic waste streams with Kreyenborg’s innovations in heat treatment of recycled pellets.

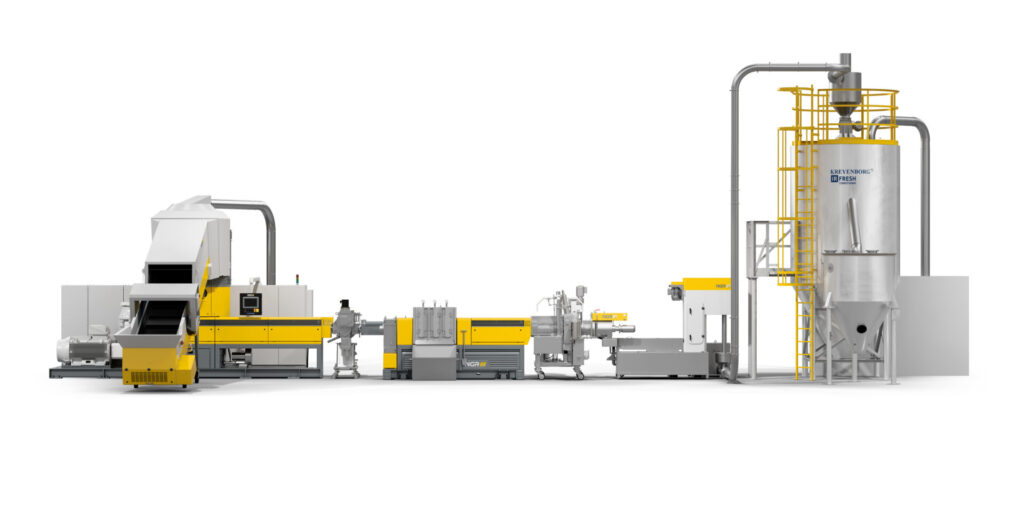

A modular, energy-efficient system has been developed that minimizes unpleasant odours in post-consumer plastics, thereby increasing the acceptance and potential applications of recyclables in high-quality applications.

Maximum Cleaning in the Melting Phase of Plastic

The process begins with an exceptionally efficient regranulation step based on NGR’s proven C:GRAN cascade technology. An initial cleaning step occurs in the cutter compactor, where warm exhaust air from the cylinder cooling system flows through the preheated material.

Optionally, a degassing zone can already be integrated before the melt filter to remove volatile contaminants. In the subsequent melt filter, all solid particles are removed from the melt stream. After filtration, the melt is fed into a high- performance degassing zone within a cascade extruder.

This “power venting section” acts as a surface generator and, along with an efficient vacuum system, facilitates maximum degassing performance. The goal is to remove volatile impurities from the melt as thoroughly as possible. After passing through the cascade, the melt is granulated, and the granules are transported to the Kreyenborg IR-Fresh Conditioner for post-treatment.

Thermal-Physical Post-Cleaning using the Kreyenborg IR-Fresh Conditioner

In the second crucial step for overall process quality, remaining low-molecular impurities are reliably removed through a thermal-physical cleaning process in the IR- Fresh Conditioner. This specially designed container maintains the material at the optimal temperature range for decontamination using a stream of hot air.

The precise interaction of the process parameters ensures consistently excellent deodorization and decontamination results, as evidenced by numerous successful tests conducted on various material streams.

For extremely stubborn volatile contaminants, the ground material can also be pre- treated before the extrusion step. This treatment removes odorous substances from the surface before they are incorporated into the melt during the extrusion process. Kreyenborg’s proven infrared technology quickly brings the material to the ideal temperature for the respective plastic. The continuous rotation of the IR drum ensures a homogeneous mass flow with a defined dwell time (first-in/first-out principle), whilst integrated rotation and mixing elements guarantee constant surface exchange. This pre-treatment, in combination with the IR-Fresh Conditioner, significantly enhances odour removal in a short residence time, greatly contributing to the overall success of the recycling process and improving energy efficiency.

Two Proven Technologies, One Goal: Producing High-Quality Granulates

“The combination of our technologies enables a substantial improvement in pellet quality and opens up new markets for recycled plastics,” explains Marcus Vogt, Technical Sales Manager at Kreyenborg.

Stefan Lehner, PCR Product Manager at NGR, also views this collaboration as a pivotal step towards promoting the circular economy and meeting its increasing demands.

The joint system is already successfully operational in the market. Furthermore, tests can be conducted with customer materials at any time to demonstrate the efficiency of this collaboration in a clear, and measurable manner.

For more information, please contact:

Kreyenborg GmbH & Co. KG: www.kreyenborg.com

NGR Next Generation Recyclingmaschinen GmbH: www.ngr-world.com

Visit us at the K-Show in Düsseldorf: Kreyenborg:

in Hall 9 / Stand A 27

NGR Next Generation Recyclingmaschinen GmbH: in Hall 9 / Stand C21