Intelligent Recognition, Efficient Sorting

Keson’s next-generation smart sorting robot marks a breakthrough by integrating AI-based visual recognition, optical sensing technology, and deep learning algorithms. It enables precise analysis of multiple material characteristics—including color, texture, reflectivity, shape, and composition—to accurately identify and sort 15 types of plastics (such as PET, HDPE, and LDPE) and various types of rubber, achieving an impressive 99.2% recognition accuracy. Compared to traditional sorting methods, it offers significantly higher precision, faster response times, and greater operational stability. It is particularly effective in separating complex mixed plastic streams, laying a solid foundation for high-value downstream resource recovery.

Industry 4.0 Architecture for Smarter Recovery

Designed with Industry 4.0 principles at its core, the system seamlessly integrates with MES, ERP, and cloud-based platforms. Real-time monitoring, remote operation, and data-driven optimization empower the system to continuously self-adapt, refine operational parameters, and learn from materials being processed. This level of intelligence transforms the robot into a truly autonomous and continuously improving sorting solution.

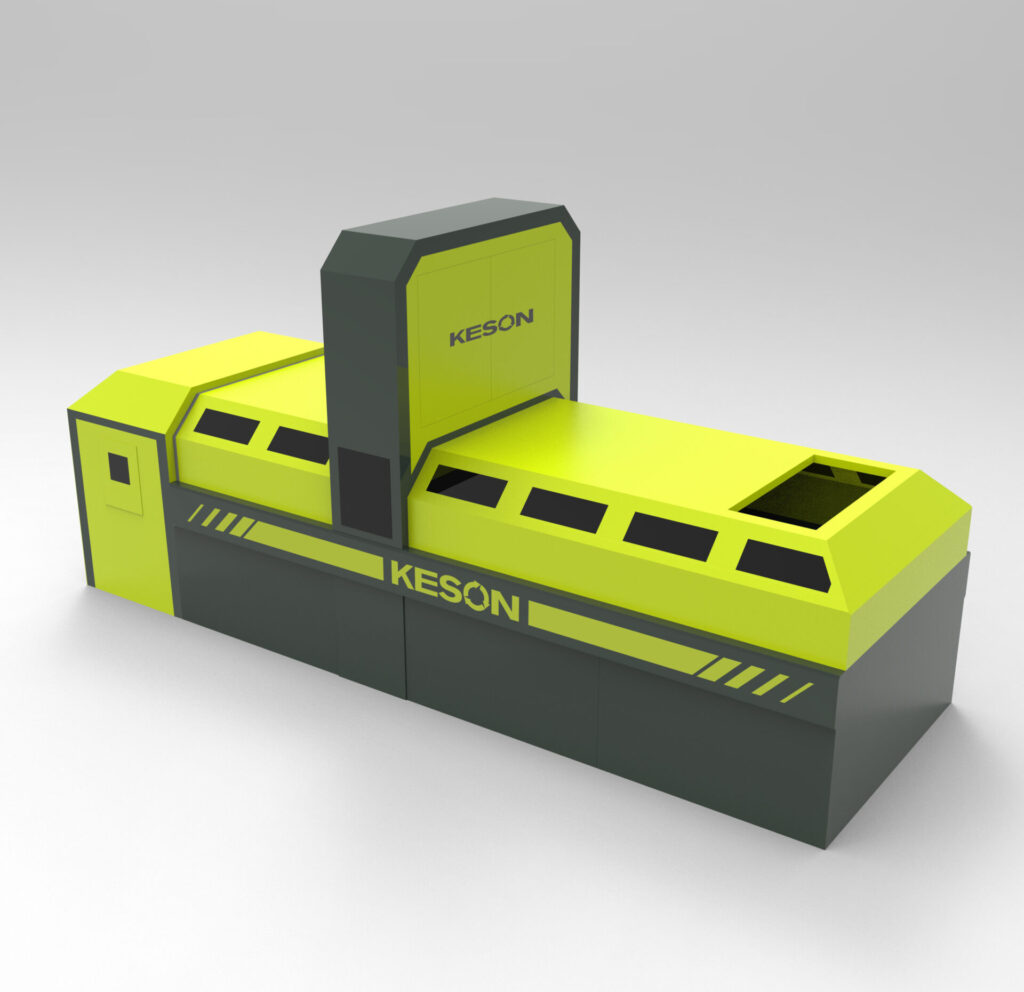

Modular and Flexible for Plastic & Rubber Applications

Whether in municipal solid waste sorting centers, plastic recycling facilities, or rubber product dismantling lines, the Keson smart sorting robot offers modular configurations tailored to specific application needs. Highly scalable and adaptable, the system can be seamlessly integrated with crushing and screening units, enabling coordinated operations from coarse separation and size reduction to precise material sorting. This ensures a highly efficient and intelligent end-to-end solution for diverse recycling scenarios.

Eco-Friendly and Energy-Efficient

With low energy consumption and high operational efficiency, the robot significantly reduces resource waste and carbon emissions. Its automation and smart control features not only minimize human labor and safety risks but also enhance the overall environmental performance of the recycling process — supporting the global push toward carbon neutrality in the plastics and rubber industries.

Visit Keson at IE expo China 2025 – Experience the Future of Smart Sorting

Keson is set to officially debut its Industry 4.0 Smart Sorting Robot at IE expo China 2025, which will be held in Shanghai from April 21 to 23. Visitors are welcome to stop by Booth N5 K01 to see the equipment in action and discover new possibilities in intelligent plastic and rubber recycling.