STADLER Anlagenbau GmbH, the globally active German company specializing in the planning, production, and assembly of turnkey sorting plants, has successfully completed the comprehensive modernization of the BZB (Bizkaiko Zabor Berziklategia) light packaging sorting plant in Amorebieta-Extano, Bizkaia. The upgraded facility was officially inaugurated on January 27th, 2026, with representatives from BZB, Ecoembes, STADLER and regional stakeholders in attendance. The modernization represents a major leap forward in capacity, automation, and digitalization, enabling BZB to significantly increase throughput, improve material purity, and future-proof operations in line with evolving regulatory and market demands.

BZB, a public-private partnership involving Garbiker (part of the Provincial Council of Bizkaia) and Trienekens País Vasco, has been a pioneer in sustainable waste management and recycling in the region. Specializing in the collection, sorting and processing of packaging waste, BZB transforms household and commercial materials into valuable recyclables and plays a vital role in promoting circular economy initiatives across Bizkaia.

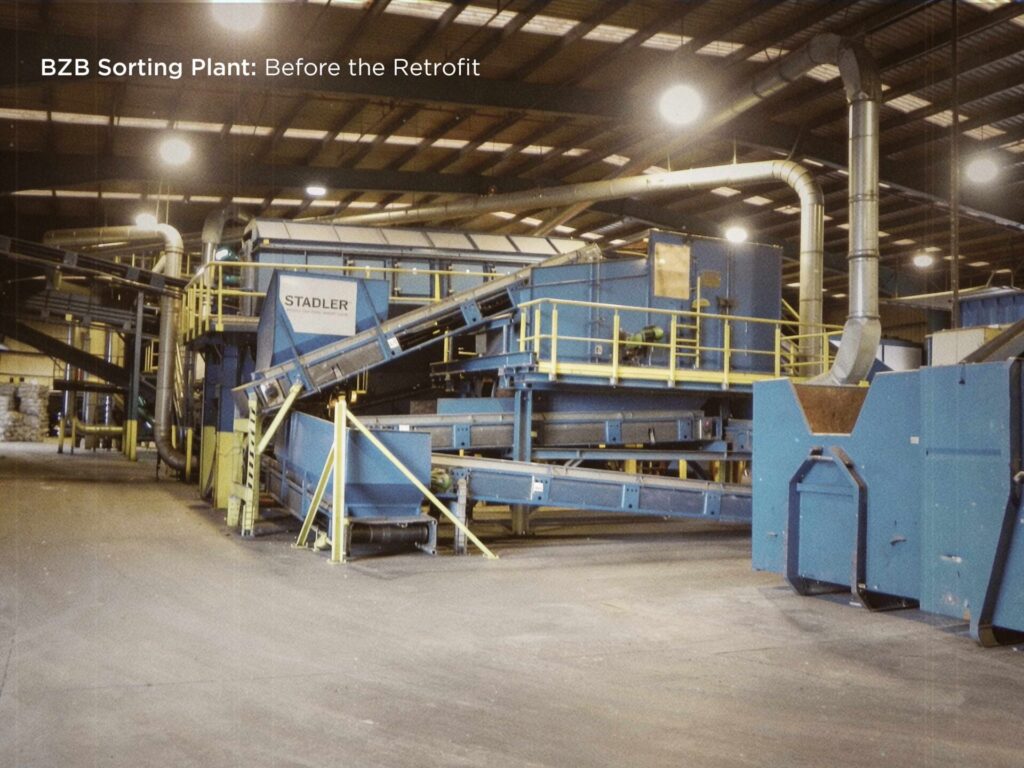

The modernization project holds particular significance for STADLER. The original BZB plant, commissioned in 2002, was the company’s first turnkey sorting facility in Spain and laid the foundation for its long-term presence in the country. Nearly 25 years later, BZB entrusted STADLER once again with the design and delivery of a new-generation plant, reflecting the strength of a partnership grounded in technical expertise and a shared commitment to sustainability and innovation.

A historic partnership renewed with cutting-edge technology

When the first BZB plant was built in 2002, it represented a bold step for both parties. At the time, Garbiker and Trienekens País Vasco placed their trust in STADLER to deliver its first complete sorting facility in Spain.

“This plant is personally very meaningful to me,” says Carlos Manchado Atienza, International Sales Director at STADLER. “It was the first full facility contract we signed in Spain when I was acting as STADLER’s distributor. Being able to sign up for the new BZB plant today as part of the STADLER team is a true source of pride. I feel genuinely honored to be part of this journey and to see how far we have come.”

“The modernization of our plant is transformative for BZB,” adds Pedro Goicoechea, General Manager Basque Country at BZB Amorebieta. “It allows us to increase efficiency and recover more materials, while positioning us to meet future challenges and sustainability goals.”

The decision to modernize the plant rather than relocate it reflects BZB’s commitment to maximizing the use of existing infrastructure while adopting the most advanced sorting technologies available. Working within the constraints of the original building required precise planning and compact design solutions, but ultimately resulted in a highly efficient and modern installation that far exceeds its predecessor’s performance.

The definition of the sorting criteria was carried out in close coordination with Ecoembes, which, as a system partner, plays a key role in the planning and implementation of the facility. BZB would like to thank the entire Ecoembes team for their cooperation.

A step change in performance and automation

The new BZB plant increases processing capacity from 3 to 8 tons per hour, more than doubling throughput while delivering higher recovery rates and cleaner output fractions. Designed to handle a wide range of light packaging waste, the facility produces high-quality fractions, including PET, HDPE, PP, PS, two film qualities, and ferrous and non-ferrous materials.

Incoming material is fed into the system through an automatic feeder and a pre-shredding stage that opens bags and loosens the waste stream. A trommel then separates the material into three size fractions, each processed independently using a combination of STADLER ballistic separators, magnetic and inductive separators, and high-performance NIR optical sorters. The sorted materials are conveyed to dedicated bunkers and baled for shipment.

The plant features reversible conveyors for flexible material routing and integrates bunker level sensors and automatic container change signaling to optimize day-to-day operations. All processes are fully supervised by a central monitoring system, ensuring high transparency and operational control.

A key differentiator of the new installation is its high level of automation. Compared to the original 2002 plant, the modernized facility uses space far more efficiently and reduces manual intervention. The improvements contribute to lower operating costs and increased overall efficiency, while also improving working conditions for operators.

Digitalization and sustainability at the core of the upgrade

One of the most innovative aspects of the project is the integration of STADLERconnect, STADLER’s digital platform for plant monitoring and maintenance. The BZB facility is the company’s first plant in Spain to benefit from STADLERconnect Predictive Maintenance, enabling continuous supervision of equipment condition and supporting proactive maintenance strategies to maximize uptime.

Beyond performance gains, the modernization strongly supports sustainability and circular economy objectives. By increasing sorting accuracy and recovery rates, the plant significantly reduces the amount of waste sent to landfill or final disposal, while enabling more materials to re-enter the value chain as secondary raw resources. Improved energy efficiency per ton processed further enhances environmental performance.

The project was completed in a remarkably short timeframe, with assembly taking just three and a half months. Commissioning was completed at the end of October, two months earlier than originally scheduled, highlighting the close collaboration between STADLER and BZB.

Customer confidence and a forward-looking vision

The successful delivery of the modernized plant has been met with strong satisfaction from the customer, as Pedro Goicoechea says: “Completing the project ahead of schedule demonstrates the strength of our partnership with STADLER and their commitment to excellence. The modernization ensures we are ready to meet future challenges while continuing to provide high-quality waste sorting services to the region.”

“I would like to sincerely thank the entire Trienekens team in Spain and in Germany and, in particular, Mr Joachim Domrös, Managing Director Trienekens, for their outstanding professionalism throughout the negotiation and installation process,” concludes Carlos Manchado Atienza. “Everything was handled smoothly and efficiently, and it has been a real pleasure working with them.”

Looking ahead, the high degree of automation and the integration of predictive maintenance ensure that the BZB plant is well prepared for long-term operational excellence. For STADLER, the project stands as a technological showcase and a powerful symbol of continuity, linking the company’s first turnkey plant in Spain with the next generation of intelligent, digitalized sorting facilities.