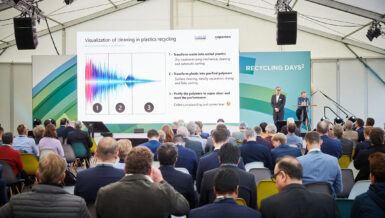

Experts from TOMRA Recycling and Novelis discussed the typical challenges in aluminum recycling and how the latest technologies – X-ray transmission (XRT), Dynamic LIBS and deep learning – are optimizing sorting processes, enhancing the purity of aluminum scrap fractions and creating new market opportunities.

Maximizing scrap utilization and input potential is essential

A key takeaway from the webcast was the critical need to maximize both the utilization of aluminum scrap and the capacity for high scrap input in production and recycling processes. Success hinges not just on incoming material quality, but also on effectively generating the necessary scrap qualities. Consequently, material quality is emerging as a central focus in product development and operational strategies.

The webcast highlighted the aluminum industry’s significant shift towards sustainability, driven by such innovative sorting technologies and recycling initiatives. Companies like Novelis, with its 3×30 vision to advance aluminum as the material of choice with circular solutions, are at the forefront of this transformation, aiming to maximize circularity and shape a more sustainable world.

Key themes raised during the webcast included:

- The business opportunities and profitability enhancements the latest innovations, particularly AUTOSORT™ PULSE (a Dynamic LIBS solution) and GAINnext™ (a deep learning-based solution), offer aluminum recyclers and processors

- Insights into an end-user’s experiences regarding recycled content, as presented by Wilhelm Kiefer, Metal Optimization Lead at Novelis

- The urgency and importance of improving the metals recycling infrastructure and technologies to keep pace with industry demand for recycled aluminum

TOMRA and Novelis also shared findings from various test results conducted at TOMRA’s Test Center and in the field, highlighting a successful reduction of individual elements in Twitch using different sorting technologies. The optimal sequence for the best overall results was found to be XRT first, then deep learning, followed by Dynamic LIBS. From 100% Twitch – a widely available yet challenging scrap type due to its complex composition – 40% of wrought aluminum was successfully extracted as exceptionally high-quality 5xxx and 6xxx alloys. The test results further highlight the future potential for recovering a broader range of aluminum alloys, including the 2xxx, 3xxx, 7xxx, and 8xxx series.

Audience insights from live polls

Live polls were conducted during the webcast. The first revealed that attendees felt the primary challenge in improving recycled aluminum content is material purity. The second highlighted that the most critical scrap grade to sort more efficiently in the future is Twitch, while the third found that participants’ primary goal when investing in sorting technology is increasing yield and purity. An interactive live Q&A session provided the opportunity to engage directly with experts from TOMRA and Novelis.

A paradigm shift towards a more sustainable and efficient future for scrap recycling

The webcast concluded with a call to action for the industry to implement optimized test sequences to enhance material digestibility and prioritize quality in production processes for improved outcomes. The ongoing innovation in scrap recycling, from processing to designing environmentally friendly alloys, is propelling the industry towards a circular economy where products are designed with recyclability in mind from the outset.

Frank van de Winkel, Business Development Manager – Metal at TOMRA Recycling, commented: “We were delighted to welcome attendees from across the globe to our recent webcast. It was a great opportunity to gather feedback from the industry on the challenges facing aluminum recyclers and post-shredder operators today, while at the same time showcase the unmatched levels of material separation available on the market today using a combination of X-ray transmission, Dynamic LIBS and deep learning technologies. Together with Novelis, we were able to demonstrate the realities of the paradigm shift towards a more sustainable and efficient future for scrap recycling, and we look forward to continuing this important dialogue.”