Cumberland has been producing world-class size-reduction equipment for decades since its launch in 1939. Given the unique demands of repurposing post-use plastic content, recycling processors need a wealth of options to stay flexible – and profitable.

Choosing a granulator

For starters, choosing the right granulator means deciding what your application needs are.

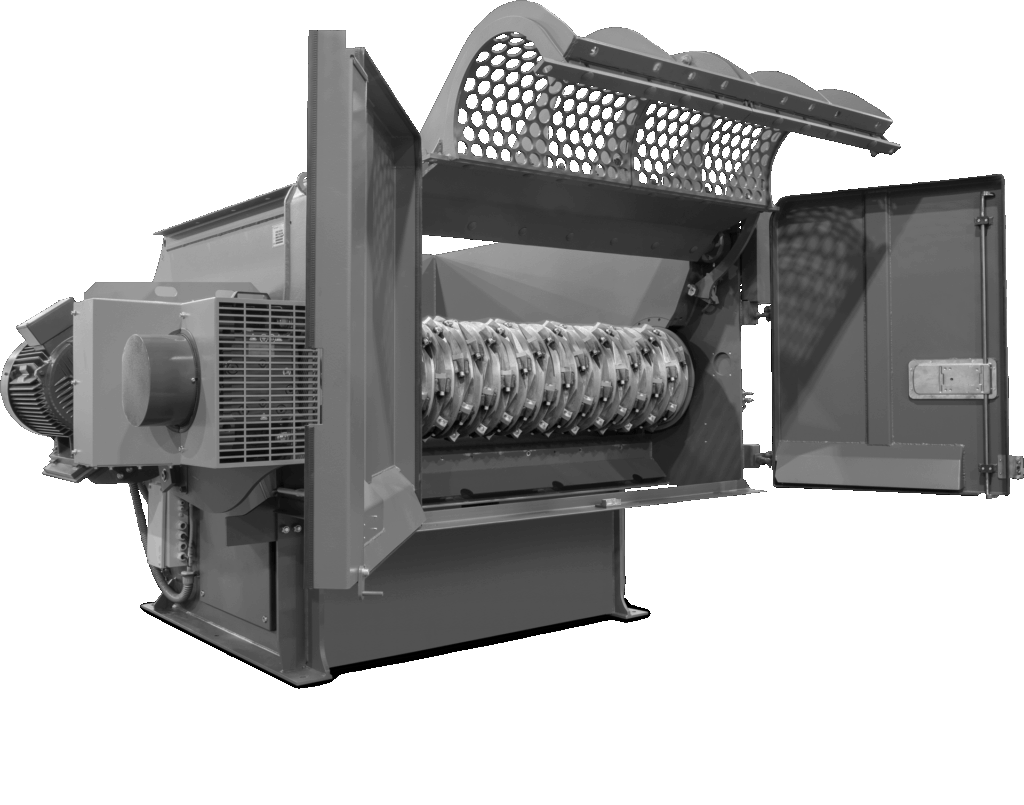

Cumberland’s family of central granulators is available with tangential or offset geometries so processors can create a machine configured to their exact process needs.

Tangential chamber geometries allow processing of larger parts through a smaller machine. A three-blade rotor complements the tangential geometry for large part ingestion. Cumberland also offers five-knife configurations. They are also ideal for large water bottles, milk jugs, HDPE detergent jugs, trash waste bins, laundry baskets and shipping cartons.

Offset chamber geometries limit material bite size and allow for granulation of thicker-walled, higher-density parts. As part of the offset chamber Cumberland granulators can include a third bed knife to increase cuts per revolution and maximize throughput for automotive parts, PVC fittings, thick plastic parts, film and sheet rolls and plastic appliances.

Unique to Cumberland granulators is TwinShear™ Technology – a scissor-cutting rotor design that provides energy-efficient granulation with a solid machined rotor pocket for industry-leading structural integrity.

Cumberland’s T50 series central granulator models – T5070, T5090, and T50120 – are designed for the big jobs in the reclamation of large blow molded and thin-walled, injection molded plastic parts as well as film and fibers. The tangential design can process many types of scrap with improved ingestion using less power, reducing plastic material to chips or granulate. The machine can be fed by hand through a hopper opening in the front or automatically from a custom-designed hopper. Throughput ranges from 1,500 to over 2,500 pounds per hour.

For more throughput, Cumberland’s X series allows throughput from 1,800 to over 4,500 pounds per hour. Featuring rotating end discs to improve airflow and minimize heat, the X series can be configured with options like multiple hopper designs, replaceable rotor knife seats, a water-cooled rotor and chamber and a digital load meter.

Granulators for big jobs

When processors face tough size-reduction jobs – for instance, with low-density fiber or heavy purgings – Cumberland offers a range of heavy-duty granulators:

- 3200 series: Features deep-welded, precision-machined cutting chamber; slide-out pivoting discharge assembly for easier cleanout; and a hydraulic actuation system for hopper and cradle opening.

- B series: A high shear rotor design maximizes every cut, while precision machined internal surfaces maximize material flow. Outboard mounted bearings reduce contamination risk and support maintenance.

- C series: A dual flywheel high-torque design breaks down the hardest materials, while a TwinShear knife design makes every cut more efficient to consume less energy. A split chamber supports faster cleanouts.

Robust size-reduction granulators like these are ideal for large-scale processing of the hardest materials in the most challenging shapes. They also excel at tire recycling and cast blocks and purgings including ABS.

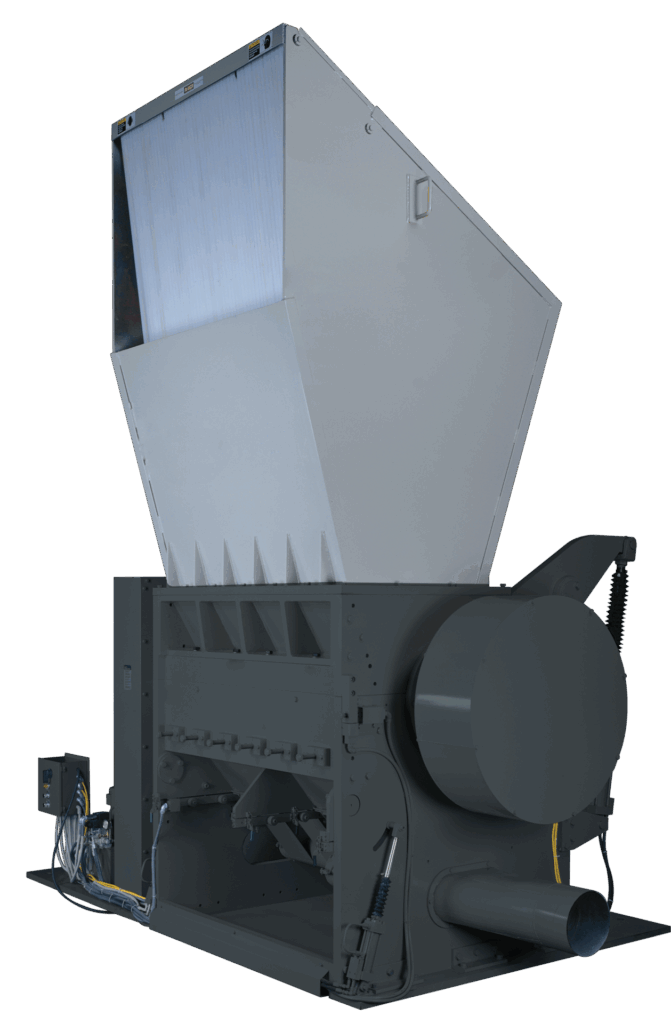

Shredders improve breakdown efficiency

Processors requiring more efficient reclamation efforts, versatile – and profitable – will use shredders upstream from their granulators to add a pre-breaking stage that relieves strain on their granulator systems.

By using an upstream shredder, processors can run higher density parts and purgings – and extend granulator life with more uptime and less maintenance.

Cumberland’s flagship shredders are the medium-size VAZ Series 1300/1600 models. New-generation VAZ shredders incorporate a wide range of innovations that improve performance, increase durability and decrease maintenance time, including:

- Solid rotor bodies

- Cardan shaft drives

- Double sidewalls

- Reversible counter knives

- Rotatable screens

- Optional hydraulic swing-up screen carriages

Meanwhile, Cumberland’s V Series shredder systems properly size plastic scrap whether they are used as standalone units, convey into a granulator or are built as a stacked system. They are engineered to handle some of the most challenging materials recycling processors encounter, including:

- Large purgings from extrusion, injection molding and blow molding

- Bulky scrap plastic

- Baled or loose film

- Synthetic fiber

- Medical waste

- Cardboard and wood

- Carpeting

- Hard plastic, fabrics and fibers

- Sheet extrusion pipes and profiles

Cumberland offers a broad range of styles within the V Series, all the way up to the VIZ Series for all plastics. The VIZ shreds a wide range of plastics with a simple, quick screen change. Its VFD inverter drive eliminates gearboxes and stops automatically when it senses errant metal. The hydraulic cutting chamber floor provides fast and safe access. Other V-ECO features include:

- Single or double-row bed knives: More shredding surface maximizes throughput and yields smaller particle sizes.

- Ram feed: Hydraulic processing ram feeds material by pushing it into the shredding rotor.

- Water-cooled rotors: Chilled water is circulated through the rotor for shredding materials with low melting points.

- Double-sided walls: Eliminate bearing contamination and prevent sidewall wear.

- “W” rotors: Innovative cutting geometry shreds flexible/fibrous or rigid/bulky materials.

For even higher capacity, Cumberland’s VAZ Series 2000/2500 features infeed openings from 63 to 98 inches long and 78 or 98 inches wide. The VTH Series (VTH 45/12/3 and VTH 65/12/3) tackles long-length plastic parts by combining a guillotine, shredder and granulator in a single machine. Production waste such as edge strips in sheet extrusion, pipes and profiles are shredded and ground in a single-stage process, enabling the plastic granulate to be returned straight to the production process.

On the other side of the size spectrum, Cumberland’s VAZ 800/1100 small rotary shredders provide one-pass shredding in a small footprint, with cutting chambers available at 32 x 42 inches, 42 x 46 inches or 42 x 51 inches.

For more details, visit www.cumberland-plastics.com.