Furthermore, the heterogeneous nature of tyre materials, comprising rubber, steel, and textiles, requires sophisticated processing technologies to unlock their recyclable potential.

The Transformative Power of Pre-Processing: Reducing Logistics Burdens

The most effective strategy to mitigate these inherent challenges lies in robust pre-processing. By reducing the size and altering the form of ELTs, shredding technologies fundamentally transform these bulky, cumbersome items into manageable small pieces for higher-density material.

This process is not just about volume reduction; it’s a strategic intervention that directly impacts the economic viability of the entire recycling chain, particularly concerning costly and logistical nightmare.

Whole tyres, with their inherent shape and air pockets, are incredibly inefficient to transport. They occupy vast amounts of space in trailers, often leading to wasted capacity and requiring more trips. When tyres are shredded, their bulk density dramatically increases. This means a significantly greater weight of material can be loaded into each transport vehicle, optimizing freight costs per tonne.

Instead of moving air and awkward shapes, transporters are moving concentrated, valuable material. This efficiency extends beyond outbound logistics to the collection phase as well, allowing collectors to gather more material per trip from various sources.

Fornnax’s Engineered Solutions for Optimized ELT Management

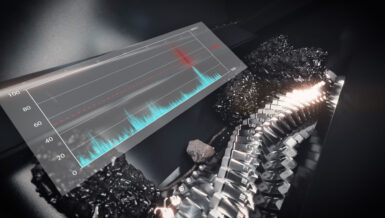

At Fornnax, we specialize in developing high-capacity, robust shredding solutions specifically designed to tackle the complexities of ELT processing. Our tyre shredders are engineered to perform across the spectrum of tyre types, delivering consistent output that is ideally suited for both further recycling and as an alternative fuel source.

Our core offerings for ELT processing include:

Primary Shredders: These powerful Fornnax SR-Series Primary Shredders are the first line of defense against whole tyres. They are designed with aggressive cutting teeth and high torque to effortlessly break down even the largest OTR and mining tyres into smaller, more manageable pieces (typically 50-150mm).

This initial reduction is critical for volume compression, immediately making the ELTs easier to store and transport from collection points to centralized processing facilities. For instance, our SR-Series Primary Shredder helped one our Australian client in substantially improving initial handling efficiency with approx. 30% reduction in transportation costs and a 25% increase in storage capacity, which enhanced their overall tyre recycling operations.

Secondary Shredders: Following primary shredding, Fornnax R-Series Secondary Shredders take the reduced tyre fragments and further process them into smaller, more uniform chips (typically 10-50mm). This stage is vital for producing steel free tyre chips various combustion applications or further granulation.

The uniform size of the output is crucial for automated material handling systems, allowing for smoother conveyance and reducing the risk of blockages, thus ensuring continuous operational flow.

Granulators: For applications requiring even finer output, such as rubber granules for sports surfaces or asphalt modification and more, Fornnax’s TR-Series granulators convert tyre chips into crumb rubber/rubber mulch, further compressing the material and enabling efficient bulk handling for specialized end markets.

Efficient Transport & Handling Through Advanced Shredding System:

The implementation of Fornnax’s shredding technology delivers quantifiable benefits in logistics and operational expenditure:

- Reduced Transportation Costs: By increasing the bulk density of ELTs through shredding, the number of truckloads required to transport a given tonnage of material drastically decreases. This directly translates to fewer fuel consumption, lower labour costs per tonne transported, and reduced vehicle wear and tear. For businesses operating across vast geographical areas, this optimization represents significant savings.

- Optimized Storage Capacity: Shredded tyres occupy far less space than whole tyres. This allows recycling facilities to store a greater volume of material in the same footprint, reducing the need for expensive additional storage facilities and maximizing the utility of existing space. Additionally, shredded tyres facilitate easier handling and export in containers due to their reduced volume and increased density.

- Streamlined Material Flow: Uniformly shredded material is easier to handle with automated conveyor systems, forklifts, and loaders. This reduces manual labor requirements, minimizes equipment strain, and accelerates the movement of material through the processing chain, improving overall operational efficiency.

- Enhanced Safety: Handling smaller, more consistent material reduces the risks associated with moving bulky, irregularly shaped whole tyres, leading to a safer working environment for personnel.

By strategically integrating robust shredding solutions like those offered by Fornnax, tyre recycling businesses can convert the challenge of ELT bulkiness into an opportunity for operational efficiency and significant cost reduction. This pre-processing step is not just about preparing material for recycling; it’s about fundamentally transforming the economics of the entire End-of-Life Tyre value chain, making sustainable recycling more viable and profitable.