The benefits of waste volume reduction are both obvious and significant. Volume reduction contributes to more productive use of store and warehouse space, and minimizes the number of waste pickups needed, resulting in lower waste transport costs and reduced CO2 emissions. There is a wide variety of compaction equipment for small and large-scale waste management.

Balers are especially useful for managing recyclables like cardboard, plastic wrap, PET and aluminum. By neatly compacting recyclables into standardized bales, balers improve recycling efficiency, cut down on clutter, and provide a more profitable waste management.

Balers come in different shapes and sizes; from small vertical balers for convenience stores and restaurants, big vertical balers for supermarkets and manufacturing industries, multiple chamber balers for creating an internal sorting and recycling point to semi- or fully automated horizontal balers for large-scale waste handling in warehouses, distribution centers and recycling stations.

In a small business, where the floor space is of the essence, a compact baler that takes up less than 1 sqm can be the optimal solution providing effective volume reduction yet generating light bales that can be easily removed and transported internally on a trolley.

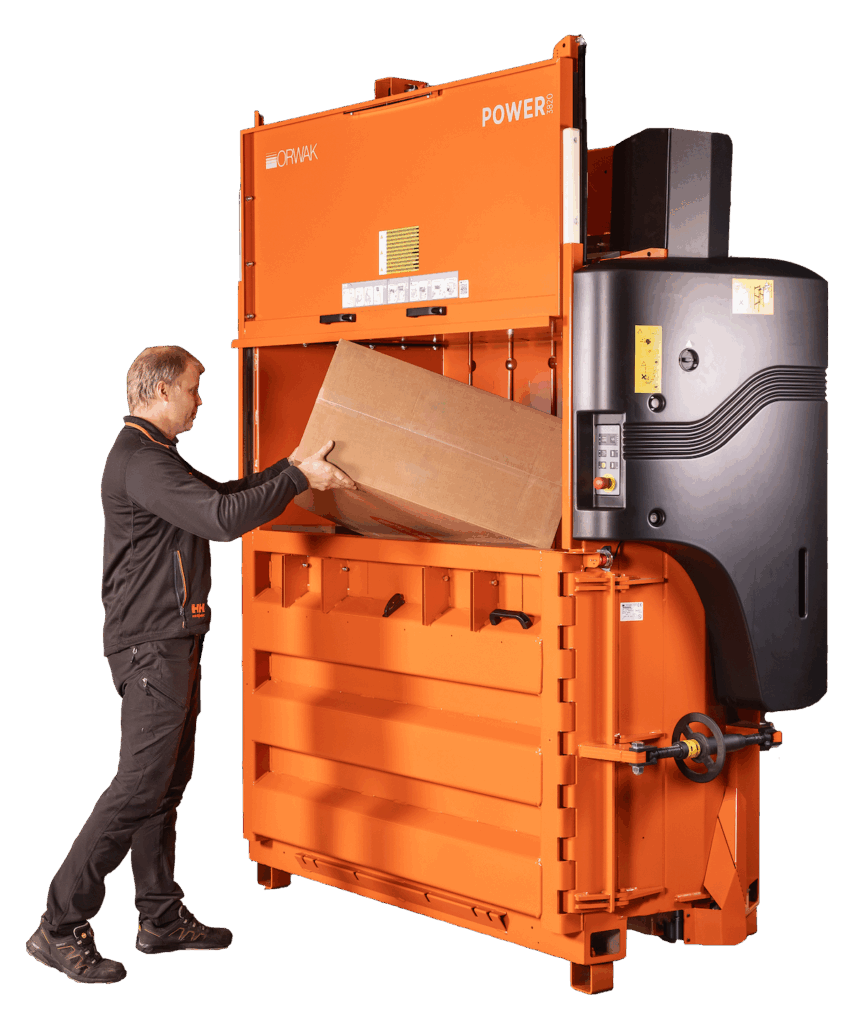

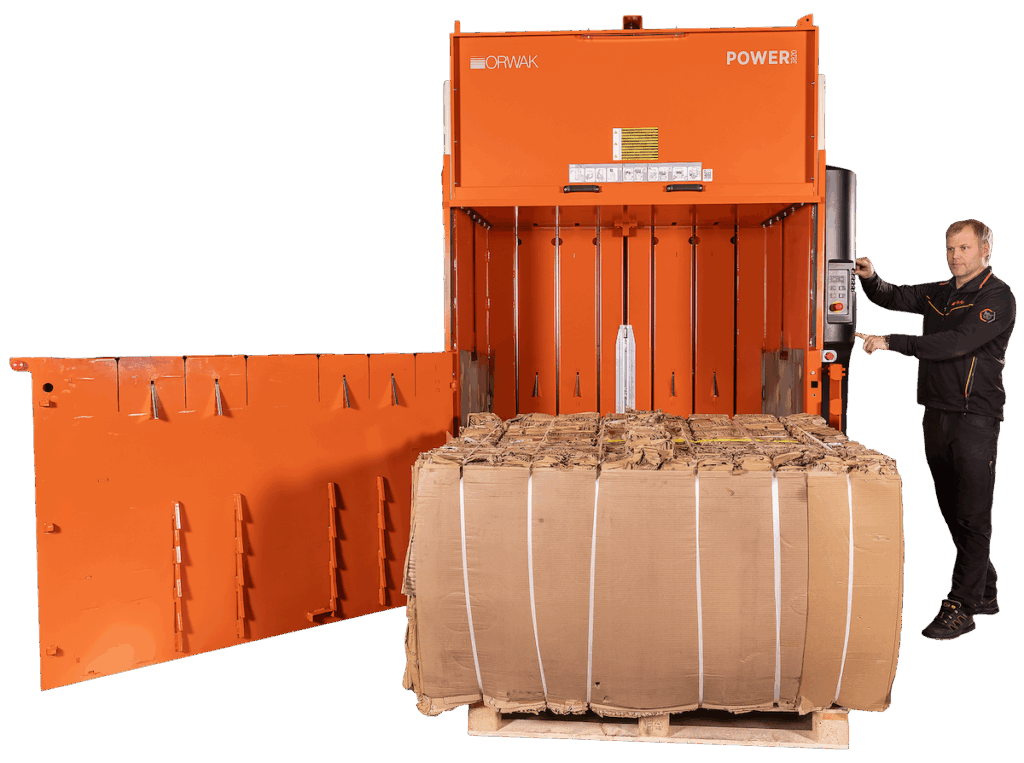

On a busy Monday morning when cardboard boxes are piling up in the store, factory or warehouse, a big vertical baler strategically installed where the goods are unpacked, makes a difference! No manual cutting or folder is required, which saves time and energy. The staff can easily load the packaging waste into the baler, close the shutter and walk away. The machine transforms the bulky boxes into thin cardboard layers in a dense bale. Sorted and compacted recyclables normally generate an income when delivered to a recycling company.

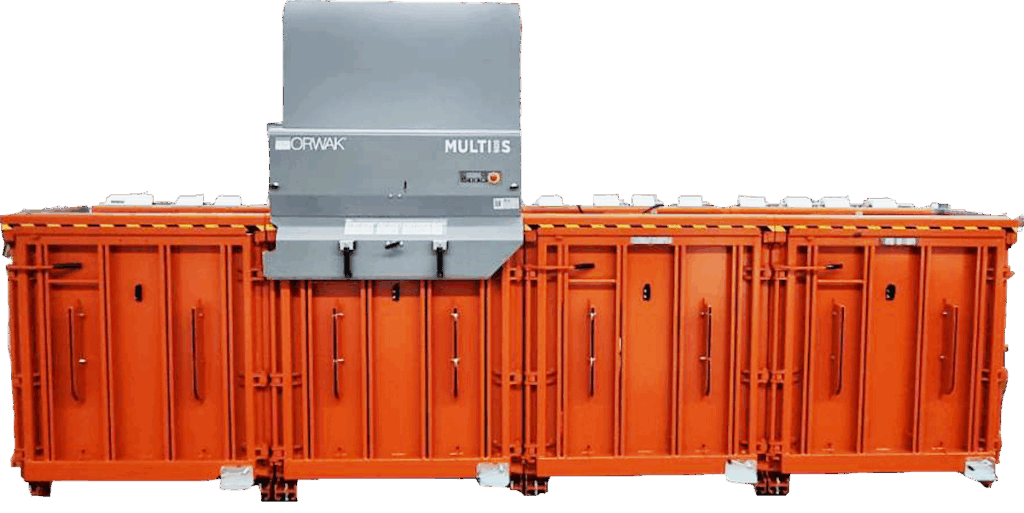

Cardboard boxes, shrink film, wooden pallets, straps, metal cans and on top of that shredded paper from the office. Many companies are dealing with a lot of different waste fractions and lack of space for a regular outdoor recycling station is often a challenge. Then a multi-chamber baler can be the answer! It comes with numerous chambers – one for each waste fraction. The baler chambers have a much smaller footprint than standard containers for loose waste and fit easily indoors next to the packing station or production line.

Businesses dealing with large volumes of recyclables, where vertical balers are too labor intensive or bulk loading is required, can benefit from semi or fully automated horizontal balers. Semi-automatics are small horizontal balers, where the compaction cycles are automatic, while the bale tying is manual. Fully automated horizontal balers on the other hand meet the challenges presented by centralized and large-scale waste handling. They can be fed manually but are designed for continuous infeed. The whole process of compacting, cutting, tying and ejecting the bales is automatic and the loads of mill-size bales can be delivered directly to the recycling industry.

Besides recyclables, the stream of general waste can be substantial, especially in the hospitality sector. Waste compactors reduce the volume of general waste by compacting it into dense, manageable loads in bags or bins. This is an effective and hygienic waste management solution that helps minimize the number of waste pickups and reduces overflows and odors.

No matter what type and volume of waste your business generates, it is worthwhile looking into a compaction solution to save space, transport and money and thereby contributing to reduced CO2 emissions and an increased recycling rate.

Orwak is a leading provider of compaction and baling solutions and offers a broad and innovative product range to promote sorting at source and make waste management more profitable. The headquarters and the production are in Sweden, where Orwak has been designing and manufacturing waste compactors and balers since 1971: https://orwak.com/