Salling Group’s headquarters is located in Braband outside Århus, Denmark. The company owns retail chains including Netto, fötex, Bilka, Salling and BR and has stores in Denmark, Germany, and Poland. To Braband comes OCC (Old Corrugated Cardboard) and plastic from approximately 250 of a total of 716 stores in Denmark.

– Previously we hired a company to collect and bale the material before we sold it, but we realized there was an opportunity to turn this expense into revenue instead. We decided to invest in our own baler and now we make the bales ourselves and make more profit, says Kasper Bech Guldmann, senior category buyer at Salling Group.

Store bales become export-ready bales

The material arrives at the facility as bales that the stores themselves have pressed in small vertical balers. The bales are held together with plastic strapping or metal wire which is removed before the material is placed on the large baler’s conveyor belt. Plastic film quite often comes mixed with the OCC. This is then separated to later be pressed into plastic bales.

Requirements for pressing pressure and bale size

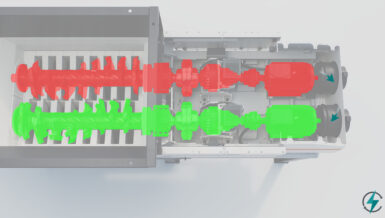

Salling Group’s baler is a Presona LP 85 VH1, a machine with pre-press technology that is very well suited to press both OCC and plastic film but also other materials like PET, household waste and aluminum cans.

Salling Group contacted several suppliers to find a baler that met their specific requirements for pressing pressure and bale size, among other things. Bale size was particularly important since the bales are transported in containers – the right bale length ensures optimal utilization of container space. Delivery time was also crucial.

– Presona met all our requirements and could deliver on time at the right price. We are very satisfied with the baler and have recommended Presona to colleagues, says Kasper Bech Guldmann.

Reliable operation and good training

More specifically, they are satisfied that the startup went smoothly and that the baler has very few operational stops. If operational stops occur, they can solve much themselves after being trained by Presona.

– We can’t wait a whole day for a service technician to come and fix small things. We must be able to solve much ourselves and the training I received from Mattias (service technician at Presona) was excellent! He was here for three days in connection with us commissioning the baler and it was a very good investment, says Kris Hougaard Bech with satisfaction.

More OCC on the way!

The baler LP 85 VH1 has high performance and currently there is unused capacity. Salling Group intends to use this by collecting OCC and plastic from even more of their stores in the surrounding area. In addition, they sometimes open completely new stores.

– The baler will have plenty to do!, says Mickael Moberg, department manager for recycling and returns with a smile.