Although the EU Packaging and Packaging Waste Regulation (PPWR) has already set rules for the use of recycled material, a number of questions remain open regarding the details of implementation. The plastics processing industry continues to be uncertain about these and other rules, and more uncertainty is bound to arise in view of the enormous quantities of plastic waste expected. Mechanical processing methods are already available, however. These offer the necessary flexibility regardless of how the laws are structured in detail. “We see dry cleaning as a key technology in plastics processing. This will be true not only until clearly defined specifications come into effect, but also in the years beyond that,” says Daniel Wienand, Head of Sales for Europe at Vecoplan. “Our shredding and dry-cleaning systems enable us to produce clean plastic flakes from different material flows. These can be used in a wide variety of applications. Dry cleaning ‘builds bridges’ between highly different applications and offers clear advantages.” Recently, Vecoplan announced the acquisition of Pla.to, a company that specialises in dry-cleaning and washing technology. Pla.to’s largest dry cleaner will be on display at the K plastics trade fair. Together, Vecoplan and Pla.to now offer a comprehensive range of services extending from shredding to cleaning of plastics.

From shredding and cleaning to clean flakes

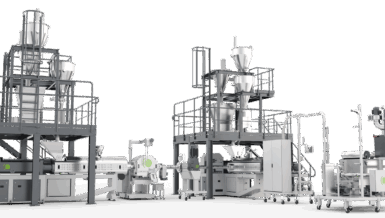

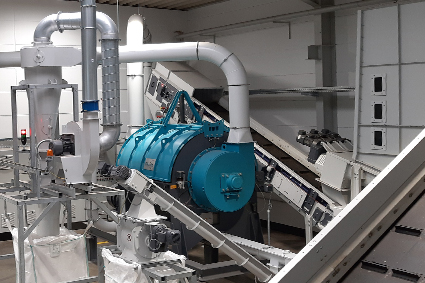

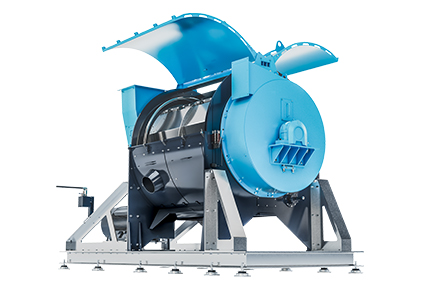

Post-consumer materials are notorious for their content of dust, paper fibres, labels and organic residues. Efficient pre-treatment of these materials is necessary for the production of clean flakes. Shredding is the starting point for all further processing steps. Vecoplan’s VIZ, one of the most versatile shredders available, reliably processes both post-consumer waste and post-industrial material, delivering homogeneous particle sizes that permit trouble-free downstream processing. The next step is drying, which mechanically removes impurities like paper fibres, dust and organic residues – without using any water. The key element of the system is a rotating baffle plate in a centrifuge with a perforated screen basket. Dissolved dirt escapes as the rotor turns, while fibres and dirt are sucked off. With its inner lining of wear-resistant steel, exchangeable rotor plates and integrated cleaning system, this solution is ideal for continuous operation. However, Vecoplan and its subsidiary Pla.to not only offer dry cleaning, but also the entire spectrum of washing technology. “Together with Pla.to, we’ve created a comprehensive solution running from shredding to cleaning. Thus we can even return complex plastic waste, such as multi-layer food packaging, to the materials cycle,” says Martina Schmidt, Senior Vice President for Recycling at Vecoplan. “We’re now ideally equipped to meet future specifications on fractions of recycled material and comply with regulations such as the PPWR.” The portfolio offered by Vecoplan and its subsidiary Pla.to covers the entire range of washing equipment: dry cleaners, friction washers, intensive washers, friction separators, high-spin dryers and thermal drying units, which process the material in an optimum manner. Together they constitute a complete washing system that guarantees output material of top quality. “By offering all of the relevant processing steps from a single source, we not only simplify our customers’ processes, we also improve the quality of the recycled material,” says Martina Schmidt. “This is an important step towards a functioning circular economy.”

Creating durable plastic pallets by means of dry cleaning

Dry cleaning has a wide range of applications, especially in plastics recycling. One key area is the preparation of material for chemical recycling. The output fractions have to meet certain minimum requirements in terms of cleanliness and homogeneity in order to make further processing possible. Pre-cleaning is beneficial even for plastic waste that is difficult to recycle. Chemical recycling breaks down fractions into molecular chains in order to make new polymers. These can then be used as feedstock for new materials. In this process, mechanical pre-treatment is critically important, so this is where dry cleaning is used. By removing dust and residues dry cleaning optimally prepares the fractions for the subsequent process.

Dry cleaning also plays a key role as a preliminary stage for wet cleaning. After shredding, coarse dirt is effectively removed so that the fractions are cleaner when they get to wet processing. This reduces consumption of water and energy and makes the entire process more cost-effective.

Dry cleaning is also practical for recycling low-quality material. Mixed plastics that are not destined for the production of high-quality recycled material can be pre-cleaned and then used as regrind material for durable plastic products like pallets or other thick-walled injection-moulded products.

Dry cleaning provides the industry with a further option for transforming substance flows into cleaned flakes. The flakes are suitable for a variety of applications, ranging from recycling to preparation for chemical recycling. Even if strict rules for ratios and quality standards for the use of recycled material are introduced in the future, dry cleaning will remain indispensable. This is because neither high-quality mechanical recycling nor efficient chemical recycling is possible without clean and homogeneous fractions. “The circular economy does not begin with legislation, it begins with technology,” says Martina Schmidt. “With an intelligent combination of shredding and cleaning, we create the right conditions for high-quality recycled material, regardless of whether the subsequent processes are mechanical or chemical. Our aim, besides meeting the statutory requirements, is to play an active role in shaping future standards for recycling.”