Transportation costs often influence purchasing decisions, so companies worldwide seek ways to reduce shipping costs, expand market reach, and gain a competitive edge. The scrap industry is no exception.

If we follow the flow of scrap going from peddler to feeder yard to shredder yard to mill, there are opportunities for margin improvements due to transportation costs at every step. The peddlers themselves do this manually by densely loading their trucks and hand-selecting only the items that are worth their time. They are often the deciders on what a scrap processor receives and what goes straight to a landfill. The cost of this service is usually overlooked, as it is simply built into the prices that the scrap processors pay for the scrap.

At the feeder yard, equipment like MOROS balers and shears can deliver significant value. These machines can turn large, scraggly piles of metal into dense, uniform packages that efficiently utilize trucks, containers, railcars, and barges, lowering transportation costs to shredder yards. Transportation costs are such a large part of the industry that many scrap processing companies also operate trucking and transportation companies, allowing them to maintain greater control over their costs.

Once material reaches the shredder yard, we’re presented with a new, seemingly counterproductive problem. Many smaller hammermills will struggle to directly process the now-densified feed material, and even in larger hammermills the bales serve as a cloak for hiding costly unshreddables or explosive canisters, increasing the safety risk and operating costs of the hammermill. The high-density bales, logs, etc. that worked so well for transportation end up becoming burdensome for the shredder.

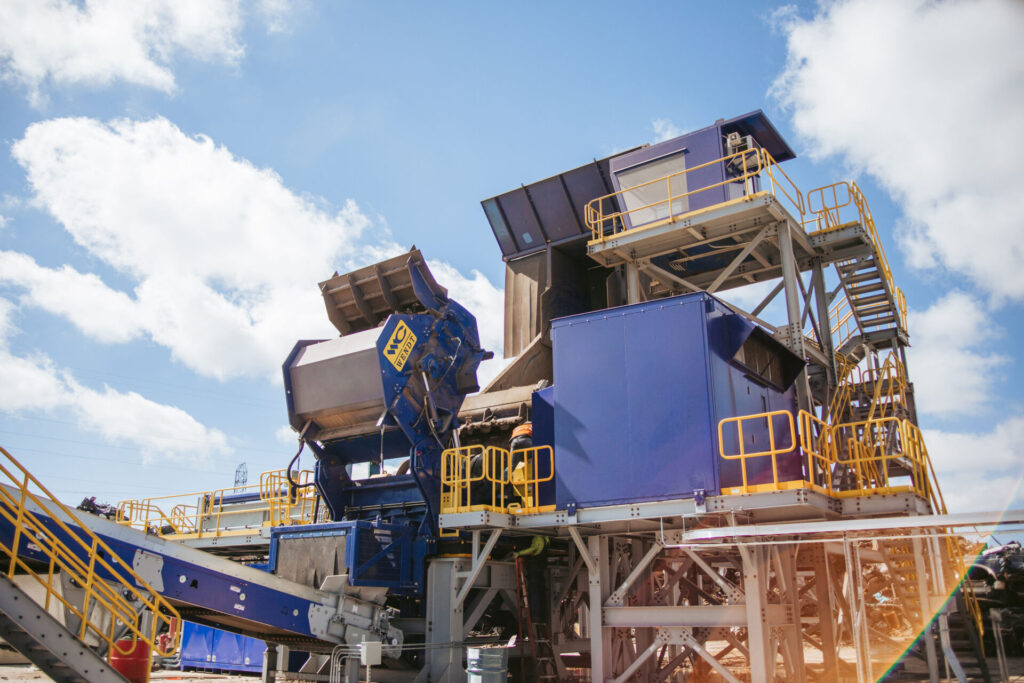

Enter Pre-Shredders. Low speed, high-torque machines like the WENDT EZR Pre-Shredder specialize in preparing densified feed material for final processing in a hammermill. They can rip things like bales, logs, and car bodies into smaller, more manageable sizes. They also have the added benefit of safely handling explosive canisters and unshreddables before they can make it into the hammermill, and they can greatly increase the throughput at the primary shredder. This, in turn, results in higher productivity, higher uptime, and lower operating costs for the hammermill while still being able to maintain the transportation benefits from the feeder yard.

Fully prepared, pre-shredded material moves to the Hammermill, the heart of the scrap processing business. Hammermills serve two critical roles when shredding scrap metal – liberation and densification. These processes work together to remove steel contaminants like ASR (auto shredder residue) and significantly increase steel density for efficient transportation to the mill. Liberating and removing contaminants, particularly copper, is critical when selling shred to a steel mill, as any impurities in melt are extremely costly to correct. Modern WENDT Hammermills can achieve final shred densities of 70 to 100+ pounds per cubic foot, a roughly 400% improvement over initial feedstock.

At these densities, the cost to transport material to the steel mill is only a fraction of what it was before densification. Higher densities also enable better liberation of impurities, allowing for efficient separation in ferrous and non-ferrous recovery systems. The result: increased metal yield and quality.

Hammermills represent the largest investment in the process, outside of the steel mill itself. As a result, they aren’t found on every corner, and scrap often travels significant distances for processing. Every improvement in transportation efficiency expands the service radius of a Hammermill.

Finally, our finished and prepared shred arrives at the steel mill for its last step. It’s been moved multiple times, over many miles, touched by many hands and machines, and put through several processes to perfectly prepare it to be turned into new steel – and between every step in the process, there were freight costs to contend with.

WENDT CORPORATION provides complete solutions for every stage of this journey. From MOROS Balers and Shears to WENDT Pre-Shredders, WENDT Hammermills, and comprehensive downstream systems, WENDT combines advanced equipment, proven processes, and the latest technologies to give our customers a competitive edge. Since 1977, WENDT has specialized in integrated shredding and sorting solutions for ferrous and non-ferrous metals.

Backed by decades of industry experience, engineering-driven design, and a full suite of value-added services, WENDT offers complete system integration, 24/7 in-house service and technical support, and robust project management and engineering expertise. No matter the size or scope of the project, WENDT delivers innovative, efficient, and future-ready solutions for the global scrap recycling industry.

Written By: Justin Kibler, WENDT Business Development Manager