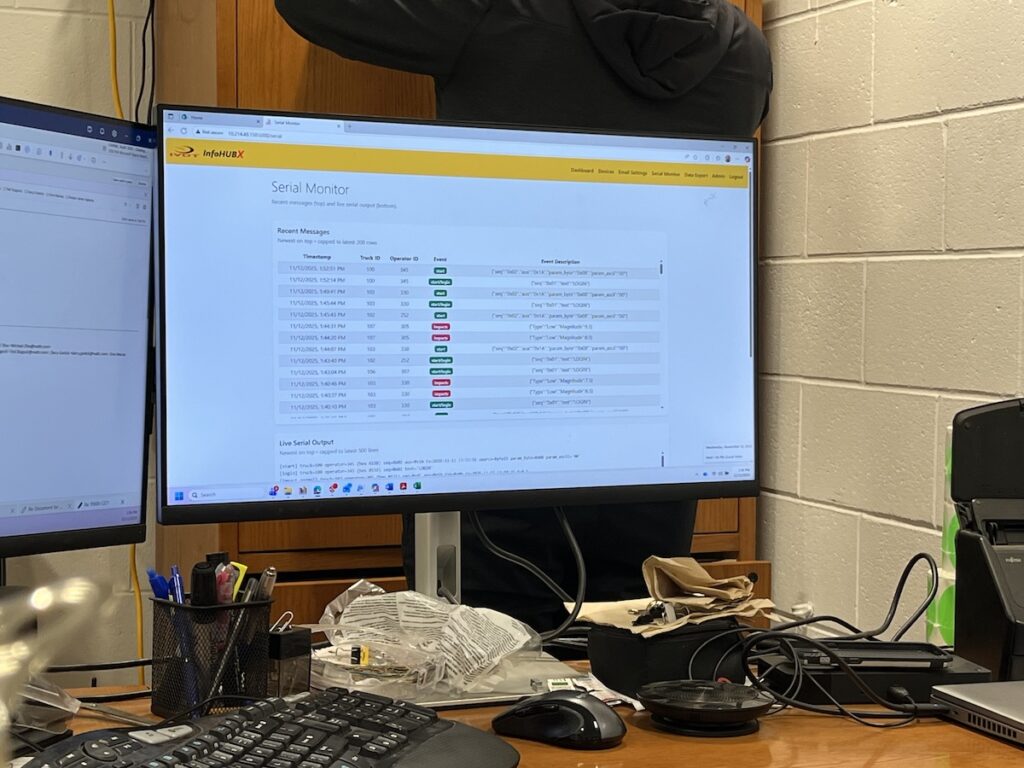

Real-Time Visibility That Reduces Guesswork

Metal recycling operations are in constant motion—loads arriving, materials being processed, equipment moving nonstop. InfoHUBX gives managers a real-time window into everything happening on the ground. From equipment status to weight data to operator activity, the system centralizes information that would otherwise be scattered across clipboards or siloed software. The result is fewer surprises and more proactive decision-making. Yard supervisors can see bottlenecks forming, identify maintenance needs early, and direct personnel more effectively.

Better Data, Better Pricing, Better Profitability

Accurate weight, production, and material flow data are critical in metal recycling, where a few pounds per load can make a major financial difference over time. InfoHUBX integrates seamlessly with onboard hydraulic pressure transducer weigh scales such as ED3, capturing precise data automatically. This accuracy leads to more confident pricing, tighter inventory control, and fewer disputes with suppliers and buyers. For recyclers operating on high volume and thin margins, these advantages add up quickly.

A Safer, More Compliant Operation

Safety and regulatory compliance remain top priorities in metal recycling, especially with heavy equipment and lift trucks, variable terrain, and constantly shifting materials. InfoHUBX supports safer operations by tracking pre-shift equipment checks, documenting operator activity, and generating digital compliance records automatically. This reduces paperwork while strengthening accountability—helping protect both workers and the bottom line.

Streamlined Workflows and Reduced Downtime

Metal recycling relies on efficient movement: lifting, weighing, sorting, stacking, and shipping. Any slowdown impacts revenue. InfoHUBX optimizes these workflows by coordinating data from lift trucks, scales, yard equipment, and business systems.

With automated logs, vehicle usage, and clear visibility into equipment utilization, operations run smoother and downtime drops.

Scalable for Yards Big and Small

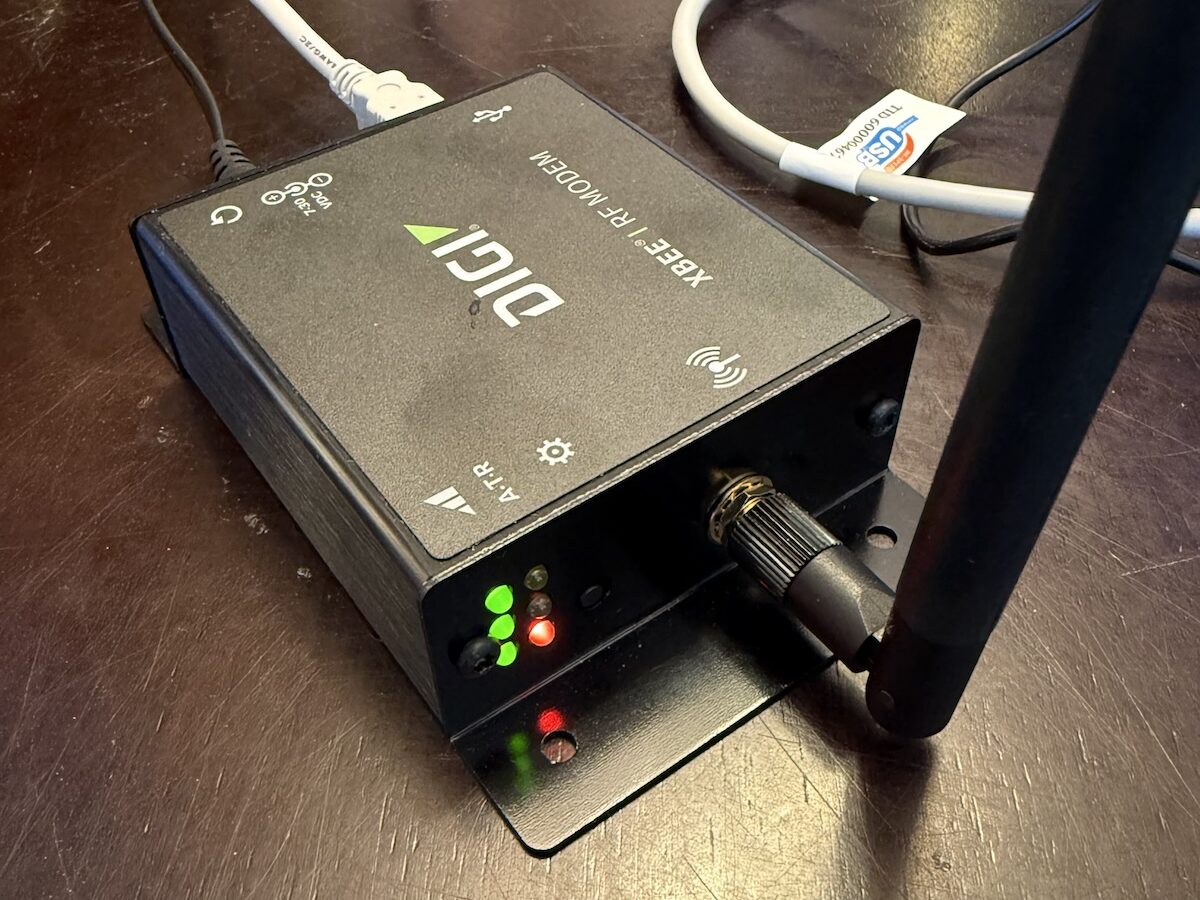

Whether a company operates a single scrapyard or a multi-site network, InfoHUBX is designed to scale. IVDT’s 900 MHz RF technology along with a powerful DIGI XBEE communication modem ensures data is accessible anywhere within the network, and modular features allow organizations to adopt only what they need when they need it.

Moving Metal Recycling Into the Future

The metal recycling industry is embracing digital transformation, and InfoHUBX is at the forefront of that shift. By connecting equipment, people, and processes into one unified platform, it empowers recyclers to operate with greater precision, safety, and profitability.

For an industry built on reclaiming value from discarded materials, InfoHUBX helps ensure that no opportunity goes to waste.