Safety and Compliance

Every ITS machine is delivered with an electronic control panel that manages all safety features required by local regulations. At ITS, these requirements are not just met—they are integrated into the design philosophy:

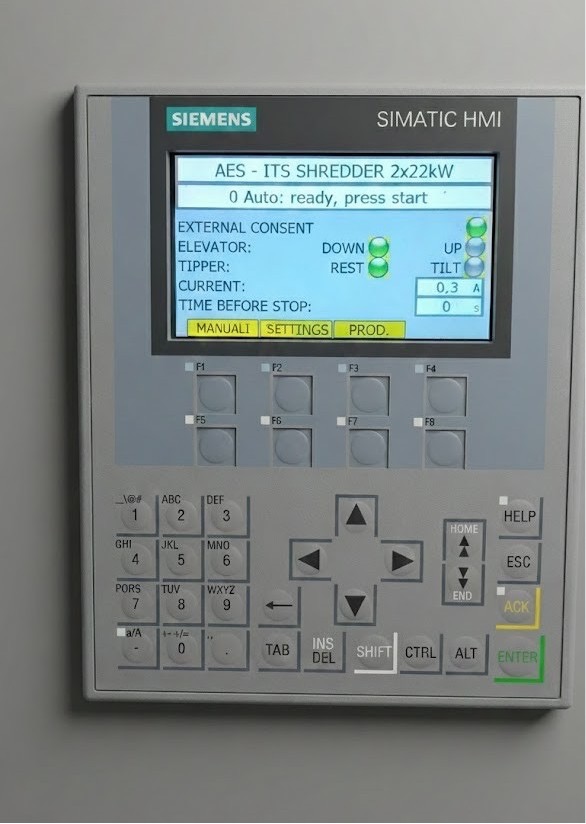

- Our electronic control panels are configured to manage all mandatory safety features.

- Machines are equipped with emergency stops, interlocked guards, and overload protections as standard.

By combining these mechanisms with our advanced data collection and monitoring systems, ITS ensures that every machine is not only compliant but also future-ready, offering both operator safety and operational intelligence

Data Collection and Monitoring

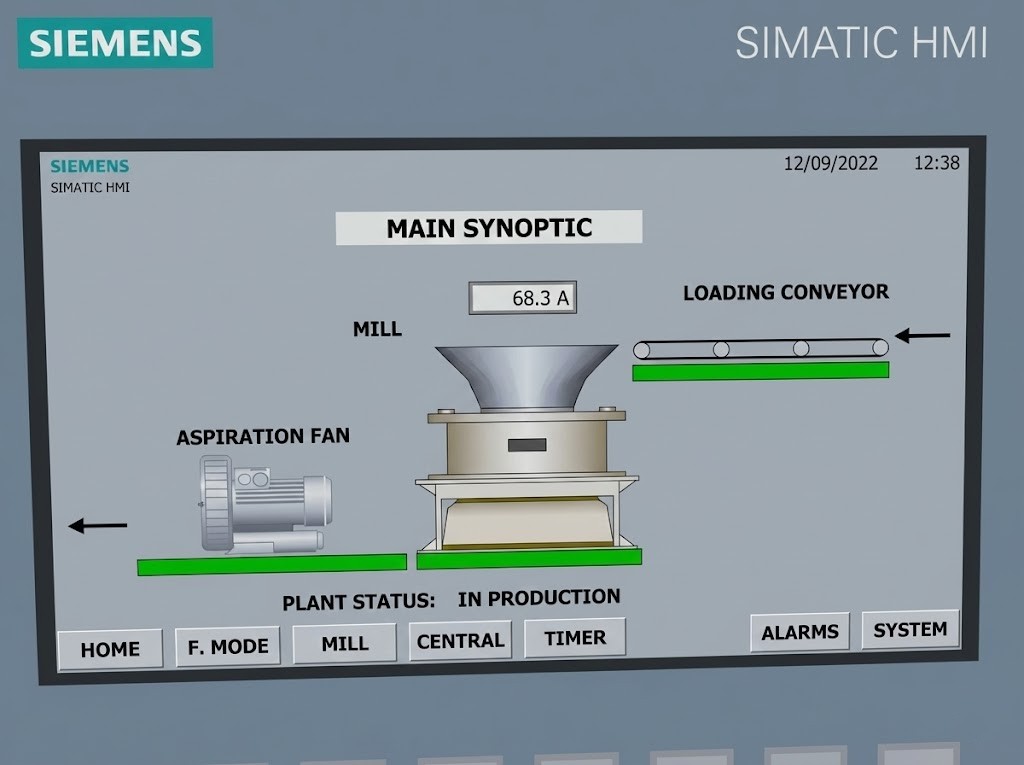

Beyond safety, ITS machines are capable of much more in terms of data management. We have extensive experience delivering equipment with integrated digital data collection systems.

Key features include:

- Operating time tracking – recording machine runtime and suggesting actions to complete scheduled maintenance.

- Behavior and event monitoring – tracking specific machine events, such as the number of blade rotation inversions in a shredder. These inversions occur automatically when a certain amperage threshold is reached, and the system logs each occurrence.

- ERP integration – collected data can be configured to communicate directly with the company’s ERP system, ensuring seamless flow of operational information.

Enhanced Measurement with Sensors

The advantages of data collection go beyond readiness. Systems can be equipped with additional sensors to provide deeper insights. A common setup involves weight sensors placed before or after shredding or grinding units. These sensors measure the exact amount of material processed, offering precise data on throughput along the recovery line.

Data collected from sensors can be also used to control loading and unloading equipment.

Predictive Maintenance

The possibilities extend even further. By combining vibration, temperature, and energy consumption data, ITS machines can support predictive maintenance. This system analyzes sensor values and suggests maintenance actions before issues arise, reducing downtime and optimizing performance.