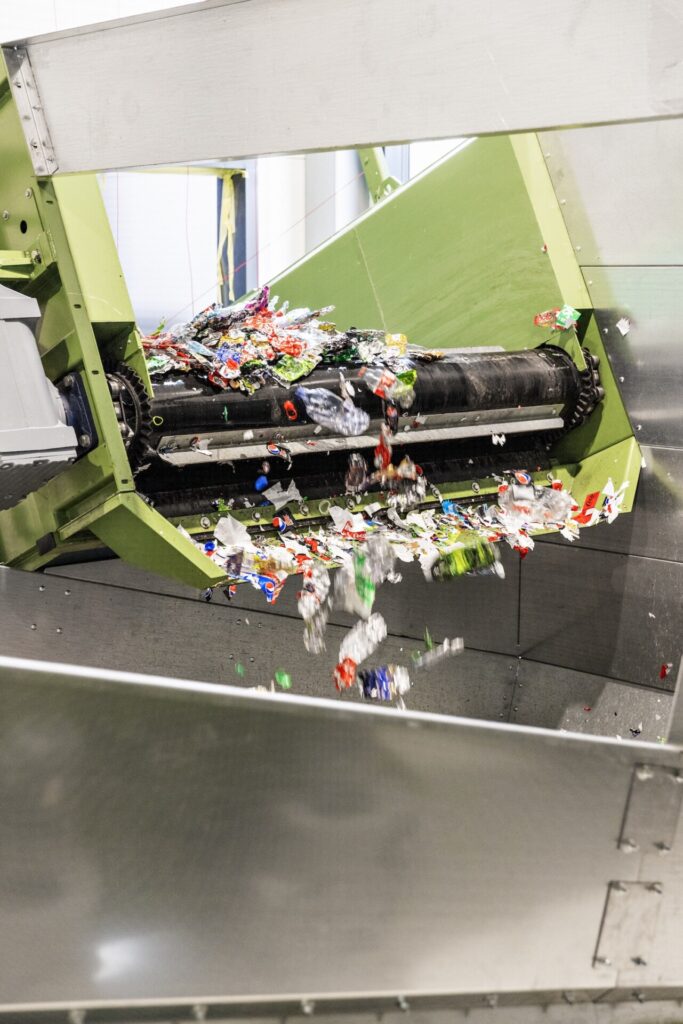

Situated near Stavanger, this new facility marks another significant step in EUROPRESS’s ongoing mission to deliver innovative, high-efficiency recycling solutions. Those eager to visualise the outcome can look to their successfully completed plant in Trondheim, which serves as a strong reference point. (see pictures)

Focused on Precision Material Separation

As with previous installations, the new plant will specialise in the highly efficient separation of PET bottles and aluminium cans. It is specifically designed to produce three distinct, high-purity fractions:

- Coloured PET

- Clear / Light Blue PET

- Aluminium Cans

Working closely with trusted local partners, EUROPRESS Umwelttechnik GmbH is managing every stage of this ambitious project — from early planning and engineering through to the fabrication of steel structures and machinery, the installation of electrical systems, and the final assembly and commissioning.

Driving Innovation in Recycling

Innovation continues to be a cornerstone of EUROPRESS’s approach. The new plant will feature two major technological advancements aimed at further boosting efficiency and output quality:

- Efficient Label Separation

In recycling processes, bottle labels present a persistent challenge by contaminating PET fractions. To combat this, EUROPRESS has integrated a newly developed air separation system, created in collaboration with a long-standing partner. This cutting-edge technology ensures highly effective label removal, enhancing the purity and value of the recycled material.

- EP:Insight App

Through the integration of their new EP:Insight App, EUROPRESS offers customers complete operational transparency. The application provides real-time access to production data via smartphone, tablet, or computer — anytime, anywhere — enabling unparalleled monitoring and optimisation of the plant’s performance.

24/7 Service for Maximum Reliability

Recognising the critical importance of operational reliability, EUROPRESS Umwelttechnik GmbH offers a comprehensive 24/7 service support package. Their expert team is available around the clock to deliver immediate assistance, remote diagnostics, and on-site interventions whenever required. This proactive service model ensures minimal downtime and maximises efficiency, providing clients with continuous peace of mind.

Strengthening the Circular Economy

With the construction of this third sorting plant, EUROPRESS Umwelttechnik GmbH once again demonstrates its strong commitment to advancing sustainable recycling technologies and reinforcing the circular economy. They continue to partner with businesses across Europe to deliver smart, resource-efficient solutions that protect the environment and drive long-term progress.