In this context, Catalan technology company PICVISA has taken a step forward, consolidating its position in the packaging recycling sector with its flagship equipment: ECOPACK.

Over the past year, the company has installed several ECOPACK units in plants across Spain —Asturias, Cáceres, Alicante, Cuenca, the Canary Islands and Castilla-La Mancha— responding to the increasing need to maximize the recovery of recyclable plastics and ensure higher-quality secondary raw materials.

This strong performance in Spain builds on PICVISA’s growing experience while expanding its footprint abroad: the company already has ECOPACK units operating in Brazil, Portugal, Italy and Turkey, markets where demand for advanced optical sorting is accelerating. The Spanish expansion highlights the momentum achieved in 2024, while demonstrating how the technology adapts to diverse regional contexts and regulatory frameworks.

Cutting-edge sorting technology

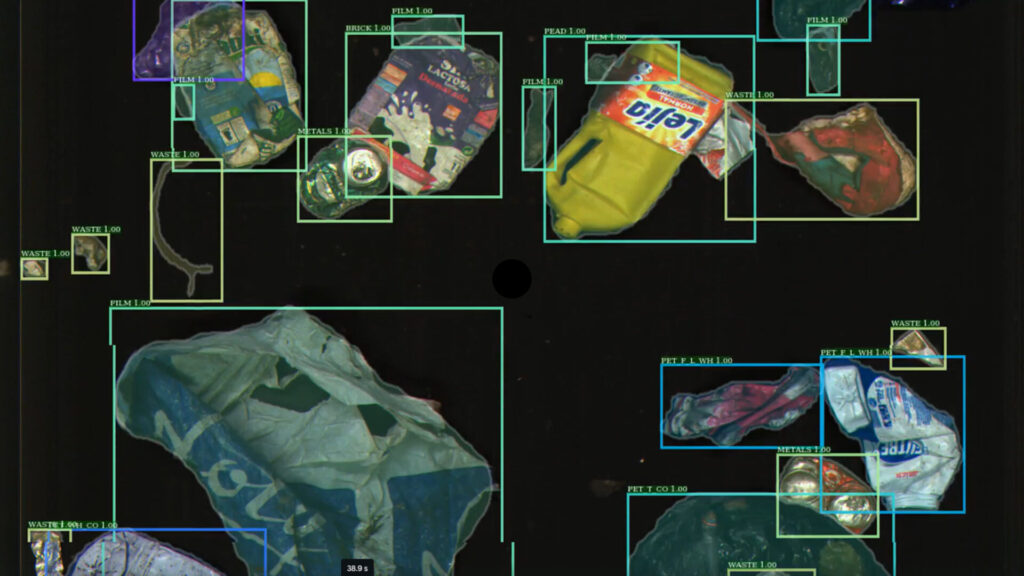

ECOPACK combines near-infrared (NIR) detection, color vision (VIS) and deep learning algorithms to sort packaging and plastic fractions with high precision and speed. It is a versatile system capable of adapting to different material flows —PET, HDPE, PP, PS, among others— while delivering high recovery and purity rates.

Its advantages include advanced automation, real-time monitoring of sorting statistics, and the ability to perform remote maintenance, reducing downtime and optimizing operational efficiency. In short, ECOPACK is not just about separating plastics: it increases plant profitability and directly contributes to achieving Europe’s recycling and circularity targets.

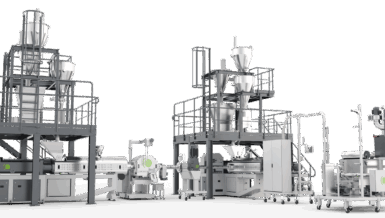

A new design: more ergonomic, more compact, more aligned with PICVISA’s brand

Far from settling with its current success, PICVISA will soon present a new version of ECOPACK that incorporates both ergonomic and aesthetic improvements. The goal is clear: to make equipment more accessible for operators and simplify maintenance tasks, while also modernizing its design in line with the company’s latest machinery.

Among the key innovations are a separate control cabinet, positioned away from the conveyor so operators can perform adjustments without stopping production; a swing-forward valve system, designed to improve ergonomics by avoiding low and uncomfortable maintenance positions; and a more compact chassis that integrates optics and flight box into a single unit. The camera cabinet has also been optimized to be smaller and better climatized, ensuring higher reliability in demanding industrial environments.

At the same time, the redesign seeks to provide ECOPACK with a more modern aesthetic line, consistent with the rest of PICVISA’s latest developments.

Continuing innovation: tackling the challenge of black plastics

Another major announcement from PICVISA in the field of plastics recycling is the development of a prototype for sorting black plastics, which is expected to be launched next year. This breakthrough is particularly significant since black plastics represent one of the toughest technological challenges in the sector. The reason lies in the carbon pigment used in their production, which absorbs near-infrared (NIR) light, making it impossible for conventional detectors to identify their composition.

As a result, thousands of tonnes of black plastics —commonly found in food trays, packaging or automotive components— end up in landfills or energy recovery plants each year instead of being recycled. Overcoming this limitation would open new opportunities for recovery and represent a decisive step toward reducing the environmental impact of plastic waste.

Commitment to the circular economy

With the evolution of its ECOPACK range and the development of new technologies to address challenges such as black plastics, PICVISA is reinforcing its commitment to innovation and to the goals of the circular economy. The company, specialized in machine vision, robotics and process automation, positions itself as a key partner for recycling operators seeking to improve competitiveness while meeting regulatory demands.

PICVISA’s strategy not only responds to the technical needs of plants, but also to society’s growing demand for effective solutions to one of today’s most pressing environmental problems: plastic waste management. With each new ECOPACK installation —from Spain to Brazil, Portugal, Italy and Turkey— and each prototype in development, the company contributes to a more sustainable future where waste is transformed into resources.