The new Halifax MRF will incorporate advanced processing technologies specifically engineered to handle the complex material streams emerging from provincial and territorial regulations taking place across Canada and deliver stronger environmental outcomes, so more materials are recycled into new packaging and products.

“The Municipal Group is proud of REgroup’s collaboration with Circular Materials on this transformative project,” said Ken MacLean, Vice President & General Counsel of Municipal Group of Companies. “As an Atlantic-based organization, we’re deeply invested in advancing recycling innovation right here at home through our affiliated companies. REgroup’s facility represents a major step forward in material recovery, technology, and environmental stewardship for our region.”

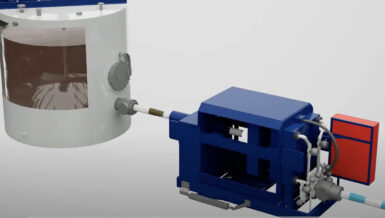

The facility will process 30 tons/hour, featuring dual infeeds and advanced sorting equipment to address the challenging material separation requirements of modern packaging waste streams. CP Group’s patented Auger Screens will be used on the front end of the system to improve processing consistency.

Advanced optical sorting infrastructure will include eleven MSS NIR (Near-Infrared) optical units providing comprehensive material identification and separation, complemented by advanced imaging systems for enhanced material recognition and quality control of aluminum. A scavenger optical sorter positioned on the last chance line maximizes material recovery rates.

The facility’s robust plastic film recovery solution utilizes density, mechanical, and NIR optical separation technologies to address one of the most challenging materials of modern waste processing. A SCADA (Supervisory Control and Data Acquisition) system will provide real-time monitoring and process optimization throughout the facility.

“CP Group is honored to be selected by REgroup to partner and deliver such an important system for Atlantic Canada,” said Richard Coupland, SVP of Strategy and Growth at CP Group. “With the growing momentum of EPR across North America, CP Group is excited to apply the unique capabilities of our technology to address the requirements of this new facility.”

Canada’s move toward extended producer responsibility shifts the operational and financial responsibility for the recycling program from municipalities to producers, requiring enhanced processing capabilities to meet recovery targets and material quality specifications. The Halifax recycling facility’s design addresses these requirements through enhanced material purity specifications required by EPR programs, improved processing efficiency to handle increased material volumes, technology integration supporting detailed material tracking and reporting requirements, and infrastructure designed to accommodate evolving packaging formats and materials.

The Halifax MRF represents Regroup’ s commitment to advancing recycling infrastructure in Atlantic Canada and is expected to be operational in early 2027.