Bunting, a global designer and manufacturer of magnetic separation and metal detection technology, supports waste management companies and MRF designers in recovering as much metal as possible while keeping purity high. On average, about 8% of the material handled in UK MRFs is metal, making efficient recovery essential.

Recovering Ferrous Metals

The process starts with ferrous metals such as steel food and drink cans. These are typically removed early in the sorting line using Overband Magnets. Positioned across or in line with conveyors, these magnets lift ferrous materials out of the waste stream and automatically discharge them into a collection area.

For smaller MRFs, Permanent Overband Magnets are common. Larger facilities, which handle higher throughputs, often rely on the power of Electro Overband Magnets such as Bunting’s ElectroMax. This early-stage recovery prevents valuable metals from ending up in landfill and ensures downstream systems can focus on non-ferrous separation.

Separating Aluminium and Other Non-Ferrous Metals

After ferrous metals are removed, what remains still contains valuable non-ferrous metals, primarily aluminium cans. Aluminium is both in demand and profitable when delivered at high purity levels.

Many MRFs install Eddy Current Separators after the manual picking stage. These machines use magnetic forces to propel aluminium cans off a conveyor and into a separate collection area.

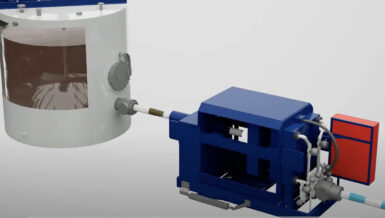

An Eddy Current Separator consists of a dual pulley conveyor. Inside the non-metallic drum cover is a high-speed rotating magnetic rotor. As aluminium enters the magnetic zone, it is exposed to rapidly changing magnetic fields that induce eddy currents within the metal. According to Fleming’s left-hand rule, those induced currents generate an opposing magnetic field that repels the aluminium away from the rotor.

The result is a clear physical separation. Metals change trajectory and are diverted by a splitter into a clean metal stream, while non-metallic materials continue forward.

Real-World Impact: Parry & Evans, UK

At the Parry & Evans pre-sorted domestic recycling site in Deeside, North Wales, Bunting technology plays a crucial role in keeping operations financially viable. Using a combination of an Overband Magnet, Drum Magnet, and Eddy Current Separator, the plant recovers around 800 kilograms of metal every hour.

This recovery represents more than just tonnage. It is a major revenue source that offsets operational costs and ensures long-term sustainability.

The Bigger Picture

Metal recovery in MRFs is about more than sorting technology. It is about efficiency, profitability, and responsible resource management. Every tonne of recovered steel or aluminium reduces the need for virgin material extraction and lowers carbon emissions tied to metal production.

With continued investment in equipment like magnetic separators, eddy current systems, and metal detectors, MRFs can boost both environmental performance and financial returns.

Bunting’s global expertise and engineering support help ensure waste processors recover every possible gram of metal, turning what might have been waste into a valuable resource.