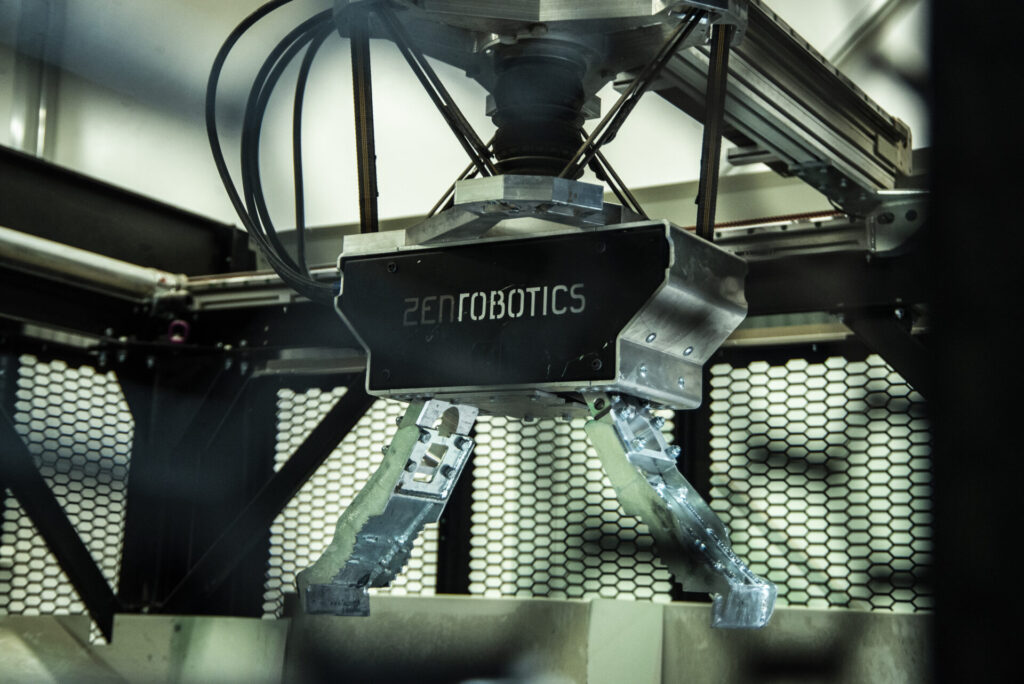

The Heavy Picker uses AI-based computer vision and robotic precision to identify and sort valuable metals and minerals from bottom ash fractions that traditional systems often miss. Stone, inert, and hardcore materials pass through, while the system sorts remaining metals and unburnt fractions directly from the belt. By automating these complex tasks, the system enhances efficiency, reduces manual handling, and improves workplace safety.

Capable of performing up to 2,300 picks per hour per arm, the system can handle objects weighing up to 40kg and measuring up to 1.5 metres in size. With the flexibility to deploy as many robotic arms as needed, it delivers up to 99% purity in recovered materials, making it a powerful solution for high-throughput, high-precision sorting in demanding recycling environments.

“This technology allows us to recover more valuable metals from bottom ash than ever before, which is a major step forward for sustainability,” said Oliver Schäppi of ZAV Recycling, CEO from January 1st. “It strengthens our commitment to the circular economy and helps us reduce landfill residues significantly.”

“However, the biggest advantage for our plant is the fact that, thanks to the Heavy Picker, we can process the material in a fully automated, 24-hour operation. This means an increase in processing capacity,” continued Mr. Schäppi.

The Hinwil site, where ZAV Recycling operates, is also home to KEZO, one of Switzerland’s leading waste-to-energy facilities. The KEZO incineration process produces the bottom ash that ZAV Recycling now processes using advanced AI robotics. This collaboration demonstrates how waste-to-energy and recycling organisations can work together to maximise resource recovery and environmental performance.

“We are delighted to support ZAV Recycling in their transition to AI-powered sorting,” said Juha Mieskonen, General Manager at ZenRobotics. “Our Heavy Picker technology is designed to help operators achieve higher recovery rates and operational flexibility while making waste treatment safer and more sustainable.”

“As a global pioneer in AI-based sorting, ZenRobotics has supplied systems to recycling and waste-to-energy plants worldwide. Our collaboration with ZAV Recycling highlights how News Release public waste management organisations can successfully adopt cutting-edge automation to improve sustainability and economic outcomes.”

For more information please visit www.zav-recycling.ch/en/story or www.terex.com/zenrobotics. Alternatively, view a video showcasing the Heavy Picker in action at ZAV Recycling’s Hinwil facility, demonstrating how AI-driven robotics is transforming bottom ash processing and delivering measurable sustainability benefits.