The shredding of metal is a necessary step in recycling, regardless of where it comes from or where it ends up. Recycling aluminium, copper and zinc, sheet metal, profiles and scrap metal can not only save billions of euros in climate and environmental costs. Using scrap instead of primary material also avoids millions of tonnes of CO2 emissions. However, there is no simple, general answer to the question of which shredder is best suited for metal shredding, because not all metals are the same. The right shredding solution depends on the shape, toughness and objective of the metal recycling. Whether it is volume reduction for easier processing in smelters or for better separation of different metals and composite materials.

‘Our XR and ZR shredders are the perfect partners for recycling non-ferrous metals. Depending on the customer’s requirements for the output material, one or two machines can be used to produce the perfect output material in a single or two-stage process. The result is always a homogeneous granulate that is then well sorted and transferred to various recycling processes’, says Clemens Jäger, Sales Manager, UNTHA shredding technology.

Special features of the XR / ZR models

- Energy-efficient operation

- Homogeneous output material

- Various grain sizes possible thanks to different perforated screens and cutting units

- Easy access for maintenance and cleaning, e.g. between different material batches

- Single-stage and two-stage processes possible

- Individual adaptation to customer requirements

Customers worldwide already rely on UNTHA’s innovative shredders to recycle non-ferrous metals of various types and compositions. Their work contributes to increasing recycling rates, utilising waste in a meaningful way and conserving resources.

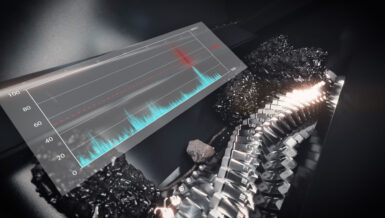

Maximum value creation with UNTHA XR3000C

Karl Karletshofer GmbH has been active in the trade and storage of ferrous scrap, non-ferrous metals and electronic scrap for more than 50 years. To round off its service portfolio, a shredding and sorting system has been put into operation, starting with a UNTHA XR3000C. With this system, the company can shred and sort aluminium, copper and zinc sheets, among other materials. The result: unmixed metal fractions that can be recycled as high-quality raw materials.

‘The UNTHA XR3000C ensures optimum shredding of different metals during operation and prepares them optimally for subsequent sorting. The result is a homogeneous and pure material that we can sell on to our customers as a high-quality raw material. They then return the metals to the material cycle,’ says Clemens Karletshofer, Managing Director of Karl Karletshofer GmbH.

Scrap iron, metals from production plants, electronic components, hard discs and circuit boards are processed at Karl Karletshofer GmbH in Germany. The company uses the single-shaft shredder XR3000C for this purpose: this shredder is ideal for recycling material streams with different compositions and can be customised to the respective input material. Depending on the material composition, size and thickness, the shredder’s operating programme can be set specifically, and different perforated screens can be used. This ensures that the material is always shredded to the desired size and that processes run efficiently. The shredder is driven by slow-running water-cooled synchronous motors – UNTHA Eco Power Drive – and is therefore particularly powerful and energy-efficient.

Clemens Jäger, Sales Manager, UNTHA shredding technology: ‘The single-stage shredding of aluminium sheets to a grain size of 90 mm is quite a challenge. However, our XR3000C can handle it. This shredder is the right technology for the job and can be adapted accordingly, for example with a particularly resistant design of the screen baskets to reduce wear. This enables us to achieve optimum results with the XR3000C for a wide range of customers.’

Energy-efficient two-stage shredding process

The recycling company Schaufler GmbH uses the ZR2400W two-shaft shredder for the pre-shredding of FE and NE scrap (composites of aluminium, lead, tin and zinc). The main factors were quick cleaning and maintenance, which is important in the non-ferrous sector, and low energy consumption in terms of specific energy input in kW/h per tonne. This shredder stands out in its class thanks to its impressive life cycle costing (LCC). ‘We were able to achieve surprisingly good values, especially in terms of energy consumption. Compared to other manufacturers, we are talking about annual savings of around € 70,000 in energy costs, which we can achieve by using the ZR,’ says Hubert Schwarz, Head of Processing and Process Development at Schaufler GmbH. The powerful pre-shredder with the energy-efficient UNTHA Eco Power Drive delivers high throughput rates – even with bulky and difficult-to-shred waste and recyclables. The robust and durable machine design is built for continuous multi-shift operation. The quick-change table system and simple design guarantee high plant availability. The slow-running cutting system is extremely resistant to contaminants and ensures perfect material preparation for downstream sorting plants.

Some materials need to be shredded even finer. For these cases, Schaufler GmbH has a second UNTHA shredder – the XR3000C. This single-shaft shredder ensures even better material breakdown and helps the company to efficiently process different material streams. The main focus is on the separation of individual metals by type: the purer the material, the better it can be recycled and the higher the profit. The XR3000C offers high throughput, great energy efficiency and is easy to maintain and operate.

Test operation as a decision-making aid

UNTHA offers interested parties the opportunity to test shredders intensively. The requirements profile for the shredder is first defined: input material to be shredded (size, composition, etc.), desired output size and throughput rate. Customers can then test the shredder in their own company, with their material and under real conditions, and see for themselves how powerful it is. During this test run, the company is supported by UNTHA’s experts in order to achieve the best possible result.

‘Our shredders stand out not only because of their technical specifications and energy efficiency, but above all because of their performance. We are happy to demonstrate this to interested parties in person. With UNTHA live demonstrations, everyone can see for themselves that our shredders meet all their expectations,’ explains Clemens Jäger.

UNTHA is committed to finding the right shredding solution for every customer: The company’s experts take the specific requirements into account and work together to find the right solution – single or double shaft shredders, one- or two-stage solutions, etc.