Many processors have entered the used shredder market believing they found a bargain, purchasing large and seemingly capable equipment, only to face component failures after installation that ultimately raise long-term costs by hundreds of thousands of dollars.

Much of the risk comes from the age and origins of the equipment. Many shredders were produced by manufacturers that have since gone out of business or were custom-built units with little to no documentation or ongoing support. When replacement parts are required, the absence of original drawings or specifications means they often must be reverse engineered.

Even “reconditioned” shredders often only have superficial cosmetic work, typically a repaint and partial testing. The internal state of the machine remains unknown and wear or damage in major components like knife sets, bearings, and shafts often goes unnoticed until the machine fails during operation.

These failures are common and can be costly, leaving buyers with long-term expenses far beyond the initial purchase price.

“While the appeal of seemingly lower cost, used shredders continues to draw buyers, the true costs of bringing these machines into working condition can exceed six figures,” says John Neuens, Industrial Consultant for Milwaukee, WI-based BCA Industries, an established developer and manufacturer of industrial shredding and recycling equipment for a variety of industries.

First-time buyers are more likely to underestimate the severity of repair requirements and the long lead times involved. Attempts to rebuild equipment in-house or through non-specialist channels can further inflate part costs and lead to poor performance. Any downtime adds further expense.

According to Neuens, purchasing new equipment offers the greatest assurance of long-term functionality. However, when new is not an option, a machine rebuilt by the original manufacturer offers a level of reliability and technical backing that the general used shredder market cannot match.

“There are quality machines available on the used market, but they are rare,” explains Neuens. “In most cases, equipment is sold because the owner cannot justify the cost of repairs, particularly due to high part prices.”

Buyers new to the process typically lack insight into the true cost of ownership. They are often unfamiliar with the pricing of critical components like knives and shafts.

“Replacing worn shafts and knives can cost $120,000 with some shredder brands, with lead times of up to four months,” says Neuens. “If a critical part fails and is either unaffordable or unavailable in time, the resulting downtime can be financially devastating.”

New Doesn’t Have to Cost More

Neuens suggests that when accounting for these risks, new equipment does not necessarily have to cost more than used.

However, buyers should still exercise caution and conduct thorough due diligence before making a purchase. Much of the new shredder market is built around assembling machines at low cost while charging a premium for replacement parts. Some experienced buyers understand the pricing structure, but many do not. They assume high part costs are incidental, without realizing that most manufacturers make minimal profit on the initial machine sale and rely heavily on replacement parts for margin.

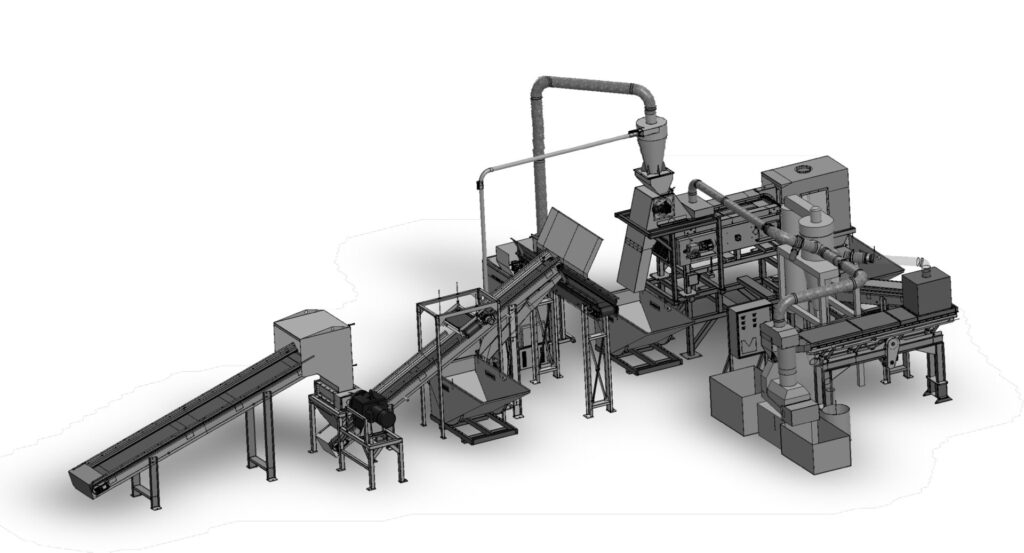

To help high-volume recyclers dramatically and cost-effectively improve their production with minimal downtime, industry innovators have redesigned and modernized shredder systems that have not been substantially updated in generations.

One example is the customizable ES2000 shredder from BCA Industries, engineered to handle the most demanding applications involving ferrous and nonferrous metals, electronic waste, truck tires, and similar materials. The system is available in both stationary and portable configurations. With 24″ diameter hard-faced knives using a base AR-500 alloy, 55″ to 72″ x 44″ cutting chambers, and 8″ 4130 Chromoly steel shafts, the unit can quickly reduce even the largest scrap materials.

Neuens says the ES2000 is an example where a “simpler” shredder design does not necessarily mean a better one. In hydraulic drive systems, for instance, the industry standard is typically to use a single large hydraulic or electric power unit.

In contrast, BCA’s design utilizes an inexpensive cluster drive system of eight small hydraulic motors to create redundancy in the power supply that eliminates catastrophic cost parts and downtime.

These cluster drive motors are off-the-shelf, and readily accessible, and they minimize cost while increasing reliability. Use of the cluster drives ensures continuous operability (at slightly lower output), even if one or more need to be replaced.

“Using a single large motor simplifies the build and requires only one assembly point,” says Neuens. “Our design involves eight separate power points that offer redundancy in the drive system, increasing complexity but resulting in a significantly better-performing machine.”

In addition, if one motor fails, the system can continue operating. A simple plate covers the failed unit, allowing the machine to run on seven motors at slightly reduced torque. Similarly, by splitting the hydraulic pumps, the system maintains partial operation even if one pump or electric motor fails—running at half the RPM but the same torque, but still functional.

This design allows businesses to stay operational while waiting for replacement parts, which can take days or even weeks to arrive. By comparison, large hydraulic pumps or motors can cost up to $90,000 to replace with lead times of 12+ weeks, resulting in excessive downtime.

“Buyers are rarely told that failure of a single component could result in operational and financial consequences far beyond the initial purchase price, that’s why we term them catastrophic cost parts,” says Neuens.

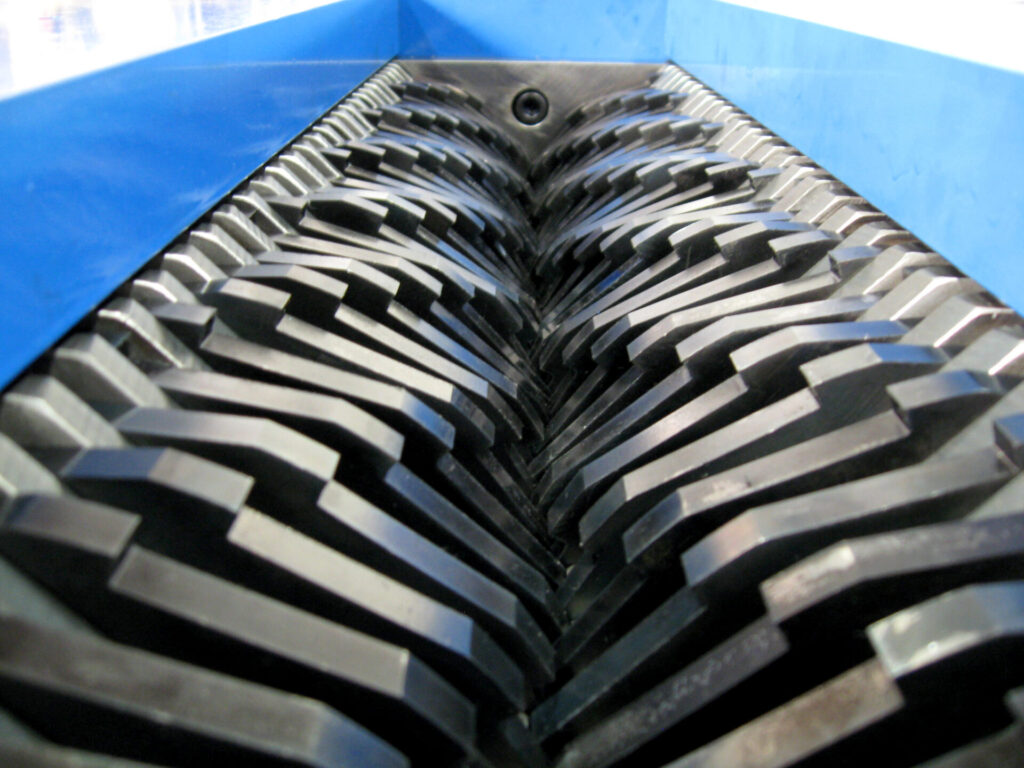

Other design features that minimize downtime include the use of 8” Chromoly shafts instead of 7” to increase usable life. In place of old HEX shaft design or a double key round shaft, the unit uses a 6 key design where the knife literally rides on disposable keys, not directly on the shaft. With the keys taking any abuse instead of the shaft, the design eliminates shaft washout and simplifies knife changes.

Because the ES2000 is designed with a double labyrinth style drop zone and outboard bearings, this eliminates any direct path of contaminants to the shaft bearings. It also allows compressed material a path to exit the shredder, eliminating the “catastrophic costs” of bearing and shaft replacement.

To further enhance production, innovative shredders like this strike at the root of the processing bottleneck.

Instead of using many shredders to progressively reduce the size of scrap, new shredder “knife” technology like BCA’s patented Triplus system (when used in the shredder) can uniformly cut to any size in a single pass without a screen, very quickly reducing scrap to a reclaimable proportion. It utilizes a unique bed knife design in a dual shaft shredder to cut the width of the material of the shredder. The size of the end-product is based on the size and geometry of the rotary and fixed knives as well as their gap distances.

Since purchasing used shredders can pose significant financial and operational risks, new machines from established manufacturers may be the better choice. While the initial price of a used shredder may appear attractive, hidden costs related to repair, replacement parts, and extended downtime can quickly escalate total ownership expenses.

A new machine from a reputable manufacturer, however, offers greater reliability, access to technical support, and the latest design enhancements that help minimize downtime. The benefits to productivity and the bottom line will be realized for years to come.