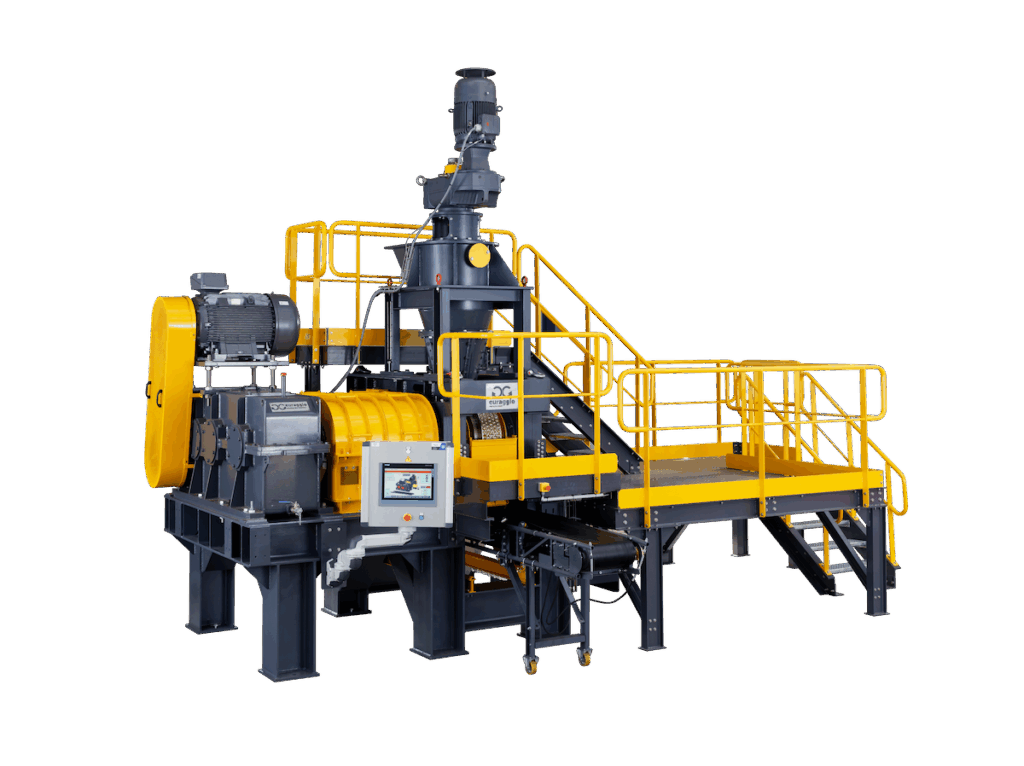

This is precisely the mission that EURAGGLO (a KÖPPERN Group company) has been pursuing for over 30 years. As a specialist in briquetting, compaction, and dry granulation using roll press technology, the company designs and installs industrial solutions to convert fine particles (0 to 3 mm) into solid, dust-free briquettes or granules that are easy to handle, transport, and repurpose efficiently.

Based in northern France and leveraging the engineering expertise of the German group KÖPPERN, EURAGGLO supports manufacturers with a clear and pragmatic goal: maximizing material recovery, minimizing bulk volumes, and reducing dust emissions throughout the value chain.

Turning constraints into resources

In a context of increasing environmental and economic pressures — such as tightening waste regulations, raw material scarcity, and the drive to reduce logistics costs — manufacturers are rethinking how to turn their by-products into usable resources. This is where EURAGGLO brings added value, by delivering robust equipment, tailored processing lines, and reliable technological expertise.

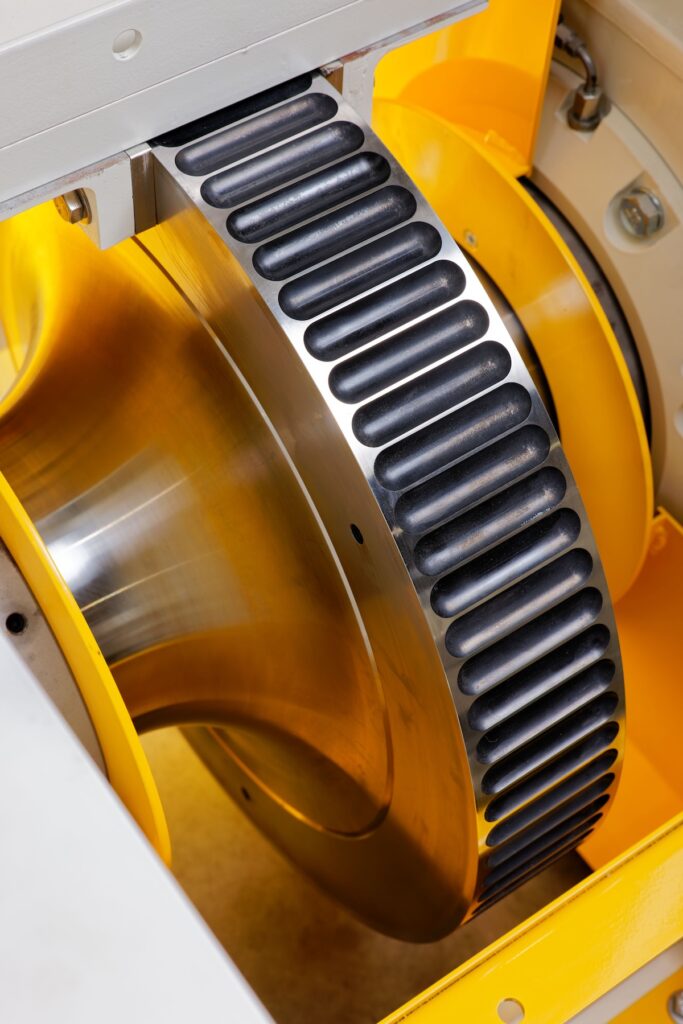

At the core of the company’s expertise lies a straightforward principle: mechanical compaction. This process allows fine powders, crushed materials, or chips to be agglomerated into briquettes. Typically, the feed material must have a moisture content below 2% and can be compacted dry or with a small amount of binder added when necessary.

Applications are numerous and span all industries generating powdery or solid waste streams. Whether dealing with metallurgical residues, mineral by-products, or dry chemical compounds, compaction technology proves to be a strategic solution whenever densification, stabilization, or material recovery is essential.

From converting metal oxides into compact briquettes, densifying mineral flows such as quicklime or carbon, to granulating chemical powders for improved handling and dosing, EURAGGLO delivers tailored solutions customized to suit the unique characteristics of each material.”

The approach is fully customized — taking into account product characteristics, process constraints, and industrial goals such as volume reduction, material recovery, energy valorization, or optimizing logistics.

Agglomeration based on experience

Several recycling companies already work with our technology to transform fines particles into solids. Capacity can range from as low as 200 kg/h to as high as 1 to 10 T/H, depending on the annual volume to be processed into briquettes.

Today the main applications for WEEE start with the production of briquettes in order to feed an EAF and to get metallic lingots. Working with all these steps allows our customers to recover tin, gold and other metals

To start the process, all raw materials need to be suitable for briquetting in terms of moisture, usually below 2% and size-range, for example minus 3 mm. For good briquette strength, the presence of oil and grease in the raw material is prohibited.

If needed, a small quantity of binder can be added in sufficient quantity and properly mixed to guarantee the briquette integrity and strength.

End-to-end support that makes the difference

EURAGGLO’s solutions cover a wide range of configurations. Each project begins with testing in the company’s pilot plant using material samples provided by the client. This phase is critical to validate technical feasibility, define equipment sizing, and produce test briquettes for analysis. Once approved, the production line is designed, installed, commissioned, and supported by experienced teams capable of ensuring maintenance and scaling support when needed.

By focusing on simple, robust, and efficient mechanical processes, EURAGGLO enables manufacturers to significantly advance their sustainability strategies. Whether to reduce landfill, cut transportation costs, or close the loop on material valorization, the results are measurable: less waste, more reusable material, and a stronger, future-ready industrial footprint.

In an era where waste becomes resource and every kilogram of material counts, EURAGGLO positions itself as a trusted partner — helping industries transform regulatory constraints into real economic opportunities.