Both myself alongside my partner and CEO, Eelco Osse, have dedicated 37 years to solving this aerosol recycling bottleneck with cutting-edge technology and a bold vision for global change.

The Problem: Safety and systemic barriers in regard to “end of life” aerosol cans pose unique risks in material recovery facilities (MRFs) and recycling centers. Loaded with flammable propellants and hazardous liquids, they’re almost always seen as potential fire or explosion hazards rather than recyclable resources.

UK waste reports from 2021, among others, link aerosols to multiple MRF fires, explaining why waste handling management and workers alike divert billions of cans to landfills or incinerators globally. This isn’t apathy—it’s self-preservation, compounded by a lack of safe recycling tools and inconsistent regulations. For example, one U.S. state classifies aerosols as recyclable, while another labels them hazardous, leaving recycling programs to improvise without standardized guidance.

The Solution: Use the proven advanced technology to eliminate these barriers. These systems come safety-certified by Lloyd’s and are fully automated technology that process almost all aerosol types. The current technology also captures the gases, collects the liquid for waste-to-energy, and produces clean metals for metal recycling.

Five global patents, including one converting contaminated propellants to EU-compliant end-of-waste fuel, back both our commitment and our approach to making a true difference—versus programs that lack the content or direction to make significant real-life changes to the aerosol environmental footprint.

Our latest innovation, a soon-to-be-patented system, achieves 100% volatile organic compound (VOC) capture for maximum recycling efficiency. Additionally, our AI-powered sorting technology distinguishes aerosols from other cans and sorts specific types—cosmetics, paints, lubricants, and more—making it compact and adaptable for any MRF or recycling center.

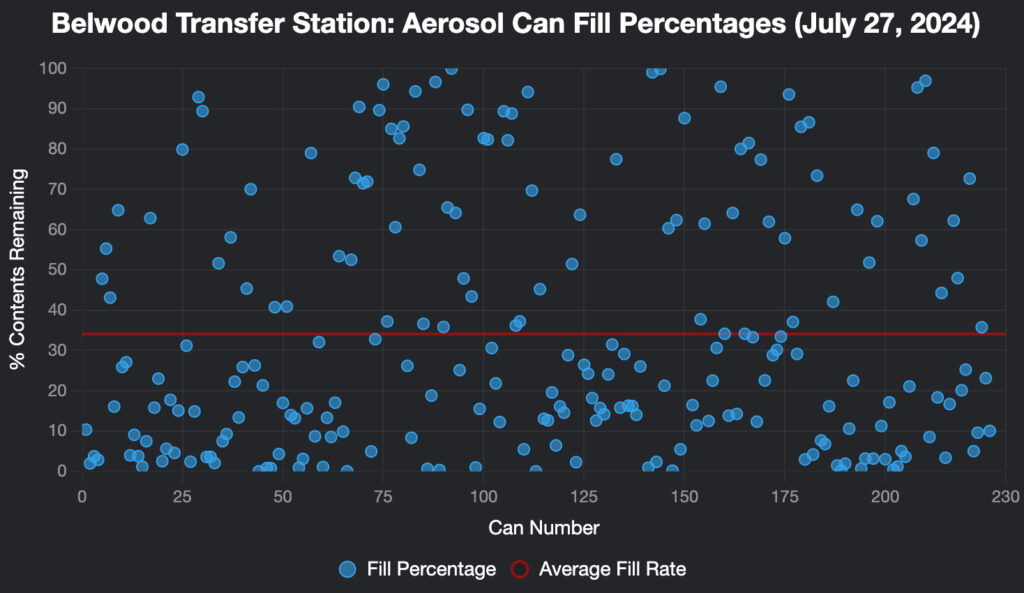

Importantly, and not to be overlooked, is our decades of data. Our data speaks for itself. The system needs big changes, not just white papers. Our detailed studies at multiple sites across multiple countries over multiple years show consistent data supporting the fact that end-of-life aerosols retain an average 25% fill rate after consumer and business use. This is a figure backed by a decade of video evidence and log data. It’s time to face this stark reality. This isn’t an estimate—it’s a proven reality.

These results highlight the untapped potential for recovery, slashing emissions and supporting a circular economy. The cost of safe and effective recycling isn’t cheap, but the environmental and safety toll of inaction is far, far costlier. Landfilling billions of cans wastes resources and exacerbates climate impacts, while inconsistent recycling policies hinder progress.

Most curbside programs reject aerosols over safety concerns, and global recycling reports often sidestep hard stats on infrastructure needs. Curbside programs need a major rethink. On the bright side, models like Germany’s 70%+ collection rate prove what’s possible with concerted effort.

With blinders off and minds open to change, a 50% global recycling rate by 2030 is achievable with the right tools, commitment, and support. I started GARA with the global mission to drive this transformation. I can’t do it alone.

GARA will have real-life offerings that will make changes that are desperately needed. This is not just my statement, but my retirement mission—and hopefully legacy. That is to turn aerosols from Earth-polluting landfill waste into circular economy assets. That will be accomplished through GARA.

More info is accessible at www.thegara.org. The goal is to be a one-stop hub uniting recyclers, fillers, supply chains, and industrial partners to share strategies, set benchmarks, and promote safe, efficient recycling.

We’ve already self-funded a PhD thesis on aluminum aerosol recycling, targeting efficiencies by addressing plastic components in metal bricks. Aluminum’s significant environmental footprint makes these innovations critical for emission reductions. These results will be available shortly.

Here is our call to action: The technology exists, the math checks out, and the urgency is undeniable. Hesitation and lack of action are now the biggest barriers—not safety. GARA can’t do it alone.

We need the aerosol industry to step up, align sustainability pledges with actionable recycling initiatives, and support standardized global programs. Join us at www.thegara.org to drive real change. Those 16 billion cans can’t wait—be part of the solution today.

For more details, connect with me on LinkedIn at linkedin.com/in/mikemackaydespray. Take action now. Support GARA. Join GARA. Watch our training videos at www.despray.com.