In September 2020, Taha Zahir from Kfar Quasem in Israel decided to expand its fleet with a second RM crusher and chose the new RM 120X. The crusher unit processes C&D waste inside a closed hall. The aggregate produced is then used as a road substructure. Because processing takes place in a hall, the lowest possible dust and noise emissions were key concerns for Taha Zahir.

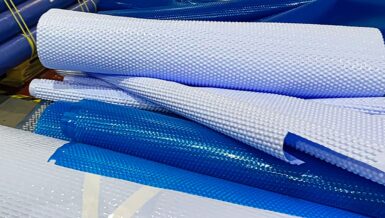

In early 2018, Taha Zahir invested in his first RM 120GO! The high-performance crusher has since been reliably crushing C&D waste to produce road substructure aggregate in a hall near Tel Aviv. Processing takes place inside an enclosed hall, which is why it was essential to the customer that the exhaust, dust, and noise emissions are as low as possible. Their volume of orders increased, which is why Taha Zahir became interested in a second, low-emission crusher. They went for the new RM 120X hybrid, which can be both diesel-electric and purely electric powered. The feed material with an edge length of up to 800 mm is now processed fully electrically to produce cuboid final aggregate (0-32 mm). In order to keep dust levels during the crushing process as low as possible, Taha Zahir also ordered a dust suppression system that minimizes dust formation using water mist generated by a water pump and spray bar.

In addition to the option of entirely diesel-free crushing, the new RUBBLE MASTER innovation also delivers impressive user-friendliness, both during operation and during maintenance. The proven RM GO! principle – which stands for intuitive machine operation and more accessible machine components

has been further developed for the new NEXT machines. With the innovative machine communication lights, the customer can now easily see the current status of the system: If the machine displays the green light, then everything is working perfectly. If the yellow light is on, the operator knows that a service is needed, and the red light indicates a warning.

Taha Zahir’s employees are also pleased about the new developments in terms of safety: As the first crusher in the NEXT series, the RM 120X keeps the operator well outside the danger zone during the crushing process. The radio remote control with a display, RM GO! SMART (optional) as well as the machine communication lighting considerably increase the safety of the machine operator. All information relating to the crushing process is displayed in the RM GO! SMART App on a mobile device, smartphone, or tablet.

Every day, approximately 1,000 tonnes of C&D waste – mixed with plastic, wood, and textiles – are delivered to Kfar Quasem. To ensure clean, high-quality final aggregate, Taha Zahir decided to install a wind sifter on both RM impact crushers. The C&D waste is now easily freed of unwanted light materials to produce a high-quality final aggregate.