This plant is considered a world pioneer in the drug recycling field. Since start-up, Biotran has always invested in the latest tech innovations to enhance its processes. One of the company’s most recent acquisitions has been the PICVISA’s intelligent robot, Ecopick, designed to tap into the potential of Artificial Vision and Intelligence in the waste management industry.

In recent years, automation in Artificial Intelligence is offering endless opportunities for the recycling industry to streamline the selection and classification process for all kinds of waste. In plants working with pharmaceutical products, such as Biotran, the need is even greater to properly identify and separate the materials, ensuring maximum safety guarantees, as residues from medicinal products can not only be harmful to the environment but also dangerous to people’s health.

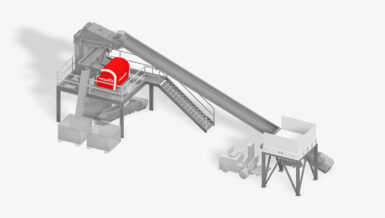

Traditionally, recycling plants had always featured a manual sorter, in charge of selecting and classifying the different types of materials, which are transported on a conveyor belt. Intelligent robots can now perform this clearly manual task fully autonomously. This boosts productivity and safety, as well as recoverable material quality. Ecopick by PICVISA provides all these benefits and Biotran has decided to add the robot to its pharmaceutical packaging and waste treatment.

The PICVISA technical team conducted a prior study of the recycling plant’s characteristics to design the most suitable robotic solution and oversaw implementation, with the corresponding dataset checks and performance tests.

Ecopick is transforming the recycling industry

Ecopick ‘s potential is based on three pillars: Robotics, Vision and Artificial Intelligence. The machine has a fully flexible robotic arm that adjusts its gripping system based on the type of object collected.

Through an Artificial Vision system, it can scan the different products, identify them among the rest of the waste and separate them for recycling and recovery at a later stage. At the Biotran plant, Ecopick is trained to classify and sort up to 8 classes of materials.

It can specifically detect mercury thermometers, biosanitary devices with and without a needle, batteries, inhalers, and X-rays, among others. Material detection is done using a visible imaging spectrometer (VIS) and, optionally, near-infrared spectroscopy.

Ecopick’s most innovative feature is that it works with a vision system featuring AI (deep learning) algorithms, enabling it to recognize objects to separate on the conveyor belt. The robot is trained to detect the shapes, colors, and textures, and later, learns with human supervision to separate different waste, with the subsequent improvement in the quality of the material recovered.

Thanks to data analysis, the robot can make online adjustments and continuously streamline sorting at the end of the line, reducing the amount of unsuitable material that reaches the end of the process. It also provides real-time access to statistics on classified materials.