Through its new software and the fifth evolutionary stage of the tried-and-tested UniSort PR, STEINERT is offering improvements in both these respects and is also paving the way into the next era of waste sorting technology.

Some sorting applications are far more complex than others and cannot be handled using conventional methods – for example sorting silicone cartridges. Since they comprise a polyethylene (PE) outer wall, they are valuable materials for recycling. Silicone residues inside the cartridge can, however, contaminate pure PE products, even rendering them unusable, and meaning that they have to be removed from the material flow.

Going beyond what is currently possible

The Intelligent Object Identifier has been developed for precisely this initial application; an Artificial Intelligence (AI)-supported object detection system for sorting machines that detects and isolates these cartridges using optically detectable characteristics. These additional distinguishing features make for a more stable sorting process, while also improving sorting results.

In the future, this technology will also support other sorting tasks or indeed make them possible for the first time. For example, STEINERT is working on an addition to the sorting program to separate polyethylene terephthalate (PET) bottles and trays that will further improve sorting reliability thanks to a new object detection feature.

What makes the STEINERT solution so special is the fact that it can be integrated without any additional sensorics and is downward compatible with UniSort machines dating back to 2018 with a combination of near-infrared (NIR) and colour cameras.

Learning from machines

This improvement has come about through software and the latest developments in the field of machine learning, especially in artificial neural networks.

Machine learning is the ability of algorithms to acquire information without being explicitly programmed to do so. In its most basic form, data can, therefore, be analysed in order to learn recognition and distinguishing features on their own and then – in the case in question – to come to a conclusion about any silicone cartridges potentially present.

The optimum precondition for this training is comprehensive and detailed data. Since hyperspectral imaging (HSI) technology was introduced in 2012, STEINERT has been generating this data and uses it today to create the training conditions for algorithms which set the bar in this industry. The data also allows users to sort better and in the long term to also develop digitalisation strategies, for example, for collaborations with customers and suppliers.

Users can then be provided with the best possible sorting result without having to configure parameters themselves or deal with programming.

Taking the all-rounder to its next level

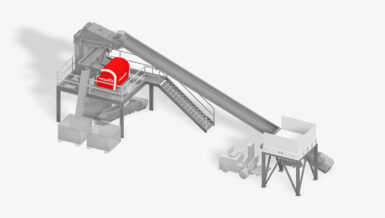

This is exactly how the latest stage of expansion of the UniSort PR, the UniSort PR EVO 5.0, came about.

The model has been put through its paces in practical trials since the start of 2019, and is the next logical step in the evolution of sorting machines. It is also a showpiece of modern technology and robust engineering work. Alongside a whole host of detail improvements, the latest iteration features a design which is much easier to maintain and delivers advanced sorting results.

Dynamic calibration monitors the spectrum of the belt lighting, which is changing all the time in response to external factors, and does so without interrupting the sorting process. Revamped light boxes ensure improved detection in the long term while also simplifying maintenance. Coupled with software updates that are being developed all the time, optimised valve blocks then guarantee a consistently precise separation of the waste flow. An optional automatic white balance reduces the intensity of maintenance, eliminating further manual stages, thereby improving staff management and making new levels of flexibility possible.

Fit for the future

The UniSort PR EVO 5.0 reflects STEINERT’s years of experience gained from several UniSort generations and the huge amounts of data that have been processed. This forms the basis for further advances in sorting performance, but also for optimising processes in the value-added chain. This in turn enables users to respond flexibly to changing material flows and recognise but also most importantly tap into new potentials.