The baling press Arno®Press D 500-3 was developed in cooperation with Cronimet, one of the leading companies in the field of stainless-steel recycling and the treatment of special alloys.

The machine was specifically adapted to the requirements in the field of stainless steel and combined with ATM Smart – a modern feature for the collection and analysis of real-time machine data which can simply be used as an app.

The first baling presses were delivered as early as 66 years ago. Some of these machines from the 60s and 70s are still in action today, which reflects the high quality and reliability of our machines. The solid construction makes them perfectly suitable for continuous and heavy operation.

Even though the majority of baling presses are used in the automotive industry, ATM has now also expanded its product portfolio for requirements in the scrap yard.

Arno®Press D 500-3 cuts with up to 3.000 KN in 3 steps and has a pressing force of up 5.000 KN. The maximum bale size is 600 x 600 mm. All wear plates that come into contact with the material are made out of Hardox® 500. The knives are also hardened and can be used several times.

The hydraulic cylinders and all other mechanic components are also produced in our own factory and correspond to the highest quality requirements. The baling press weighs over 100 to. The solid construction makes it perfectly suitable for continuous and heavy operation.

Benefits

The baling of metal scrap has many benefits. For example, pressed bales to save storage and transport costs. Furthermore, the smelting process is much easier than with loose metal scrap. This makes pressed bales more efficient.

ATM Recyclingsystems products fulfill all environmental requirements and standards. Thereby our customers contribute an important part to the responsible handling of raw materials.

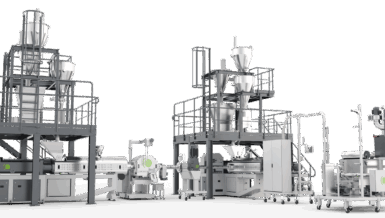

Recycling Solutions from ATM Recyclingsystems

ATM stands for Arnold Technology for Metal Recycling based on more than 80 years of experience. The company plans, produces, and provides worldwide service support for metal recycling systems for the treatment of secondary raw materials.

Our strength? High-Performance Metal Recycling Technology!