“What is the ESA app? How can we imagine the app? Could you, Dr Eggersmann, give us a brief overview before we turn to the specific situation at Interzero?”

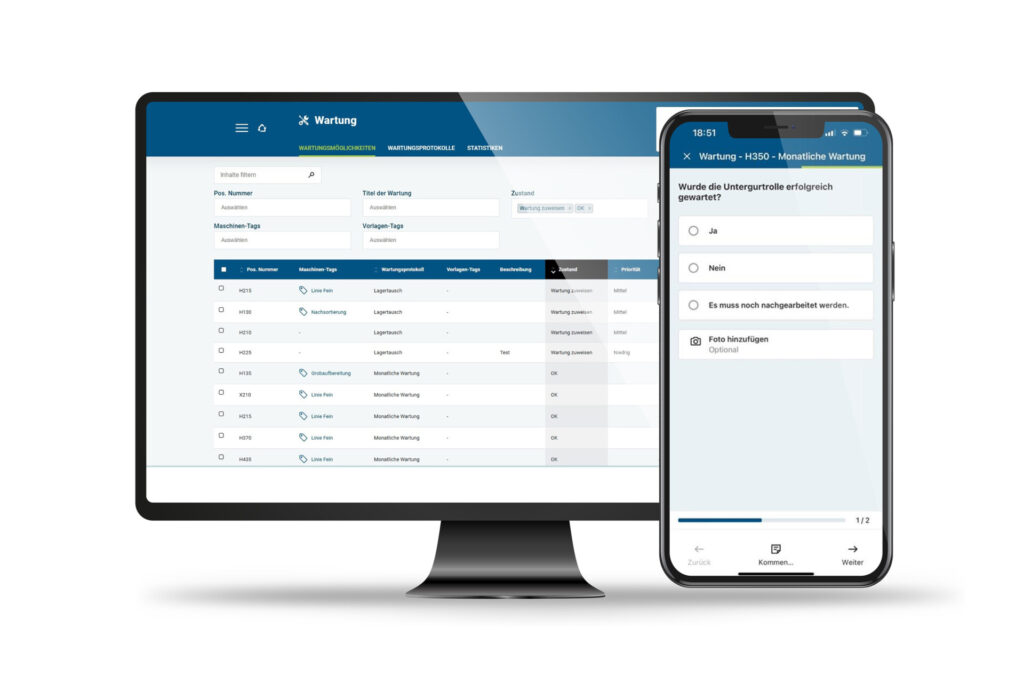

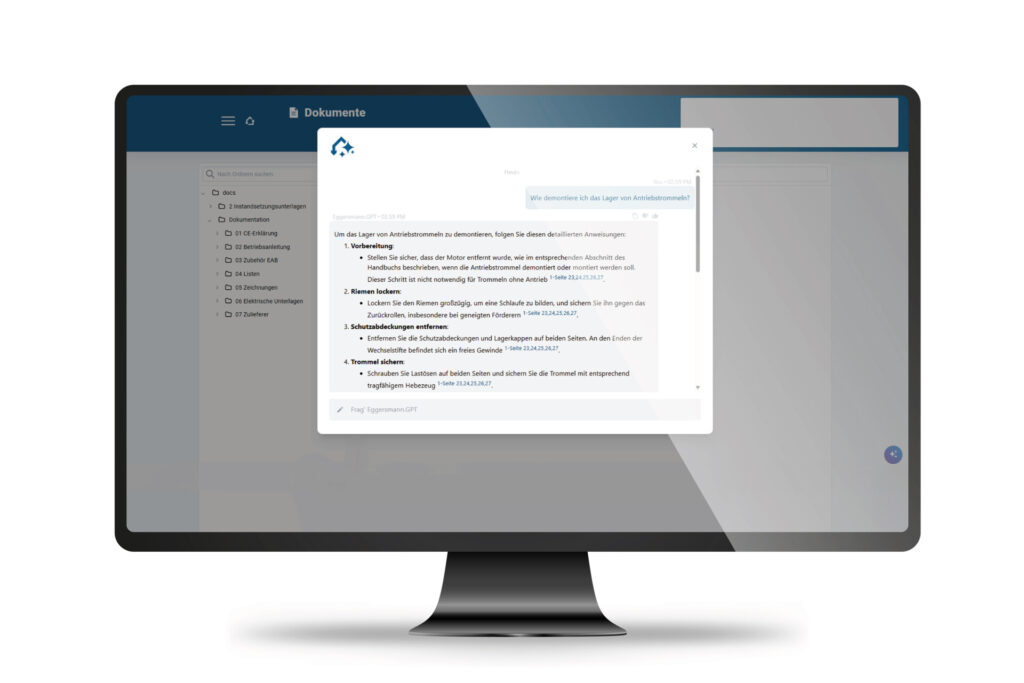

Dr R. Eggersmann: “The ESA app is our central platform for modern process management in the recycling industry. By ‘our’ I mean the companies gathered under the umbrella of the Eggersmann Recycling Technology. We cover everything from individual mobile machines to the planning and construction of large recycling plants. Together, we form one of the world’s leading full-service providers for recycling technologies. The ESA app meets the need for a digital product to optimise processes in all these areas. After all, our customers should be able to achieve the best possible results with their new plants and machines – but without digital fine-tuning, potential is always lost. We have therefore created a modular software based on the latest technologies such as real-time KPIs [key performance indicators, editor’s note] or AI-supported data analysis. The customer selects the modules they need specifically for their purposes from the performance monitoring, maintenance management, anomaly detection, logbook, and document storage modules.”

“Why did you choose the ESA app, and which of the modules just mentioned do you use at Interzero?”

T. Herkert: “We know Eggersmann as a reliable plant engineering company. They have already realised several major projects for us as a general contractor, from planning to commissioning. Eggersmann then offered us a role as a pilot customer for the development of their ESA app. This was an excellent opportunity for us to incorporate our own requirements and ideas as co-creators in the development of a complete digital solution. We therefore participated with several pilot plants. We are also using the entire ESA app. However, the modules were introduced one after the other and we therefore have varying degrees of experience with them. The maintenance management module was the first to be implemented over two years ago, and we have therefore tested it most extensively of all the modules. This module alone was able to significantly optimise our processes.”

“What exactly has the maintenance module improved? Why has this module already been so helpful? Could you elaborate this point?”

S. Leubner: “The process in a sorting plant is like a chain with many links. All these links have to be regularly maintained – and all this maintenance has to be planned, carried out, and documented. The amount of work involved is enormous, and even small simplifications have a big impact. The maintenance module of the ESA app has fundamentally changed our entire maintenance management. The app provides a status overview for the entire system with all upcoming maintenance work, which can also be called up on mobile devices at any time. Responsibilities are clearly assigned, and the digitally stored step-by-step instructions not only speed up the maintenance processes but also increase the quality of maintenance. However, the introduction of data-based maintenance will be the most drastic change. This will alter the existing system entirely.”

“You talk about ‘data-based maintenance’ – what exactly do you mean by that?”

S. Leubner: “‘Data-based maintenance’ describes a new approach: Usually, machines are maintained in predefined periods. However, these are only rough guidelines based on our experi-ence or that of the manufacturer. The reality is often completely different for individual machines. If a machine is serviced too early or too late, this is equally inefficient. The right moment is crucial and thanks to the ESA app, we will be able to determine this even more precise and automatically. We are currently still automatically collecting the necessary data with the ESA app, but soon our maintenance intervals will no longer be based on estimates but specifically on the maintenance history of the machines. This harbours enormous potential for system availability and resource savings.”

“I understand the difference in principle, but how exactly does it work? Where does this data come from?”

Dr R. Eggersmann: “As briefly mentioned earlier, the basis for using the ESA app is the comprehensive recording of all relevant operational and machine data within the plant in real time. For the maintenance module, this means that we derive the relevant key maintenance figures, such as the average time between breakdowns, from the operational maintenance data. The statistics that can be derived from this then enable maintenance intervals to be precisely tailored to machines and machine groups.”

“Have the other modules been able to change your work in a similar way?”

T. Herkert: “Performance monitoring enables us to check the most important key performance indicators such as throughput, availability and quality at any time. This is already very practical, but the true value of the module only really comes into play for us when we intervene directly in the process. Eggersmann advertises the fact that optimisations can be validated in real time, and we can now actually follow the consequences of every change almost live on the monitor – this is of great benefit when it comes to increasing plant efficiency.

Performance monitoring also helps us to define the most frequent sources of faults by providing detailed error statistics. This allows us to prioritise and tackle them in a targeted manner. As far as I know, anomaly detection offers even deeper insights here, but Mr Leubner can explain this in more detail.”

S. Leubner: “Well, anomaly detection increases our system availability even further and also helps us to ensure the quality of the end products. This is particularly noticeable with near-infrared sorters. Faulty calibrations or dirty light sources and sensors are detected much earlier by this module. Contamination in particular is associated with a considerable loss of performance – yet in the past it was often only detected after shift change. Thanks to the ESA app, we are now informed after just a few minutes, which of course has a major impact on the output of the fractions.”

“What about the logbook? Does this module also offer you such clear benefits?”

T. Herkert: “The ESA app logbook is simply a solid solution for digitising shift logs. All relevant events are recorded in a structured manner and recorded in a standardised shift log.”

“That sounds a little less convinced, doesn’t it?”

T. Herkert: “On the contrary. We want to simplify and standardise administration. That’s the whole point of digitalisation, and that’s exactly what the logbook does. The ESA app has been used to record data seamlessly so far. All information can be accessed at any time and is easy to find in one central location. As far as I know, the handover between shifts is now also faster, and the app has enabled us to reduce our documentation workload by up to one hour per day on average. The module is plainly and simply efficient – although plain, simpl,e and efficient fits even better.”

“So, your summary is positive across the board?”

S. Leubner: “Yes, because we were able to significantly increase the efficiency of the entire system with the ESA app. In addition to the time savings in documentation and administration I just mentioned, the increased system availability is a decisive advantage. The optimised maintenance and early fault detection are already resulting in fewer downtimes. We expect the upcoming switch to data-based maintenance intervals to result in a further significant increase in availability.”

T. Herkert: “Additionally, there is greater transparency. Thanks to the ESA app, we have a much better overview of the processes in our systems. We can monitor capacity utilisation live, specifically identify the causes of faults, and improve product quality.”

“Thank you for the detailed exchange and the many interesting insights.”

T. Herkert: “We gladly took the time.”